Method for predicting creep-fatigue service life of aluminum alloy piston of high-power diesel engine

A high-power diesel engine, fatigue life prediction technology, applied in the direction of testing the ductility of materials, testing the strength of materials by applying repetitive force/pulsation force, etc., can solve the problems that the practical significance is not obvious, and the damage cannot be fully considered, so as to solve the problem of non-destructive The effect of linear coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

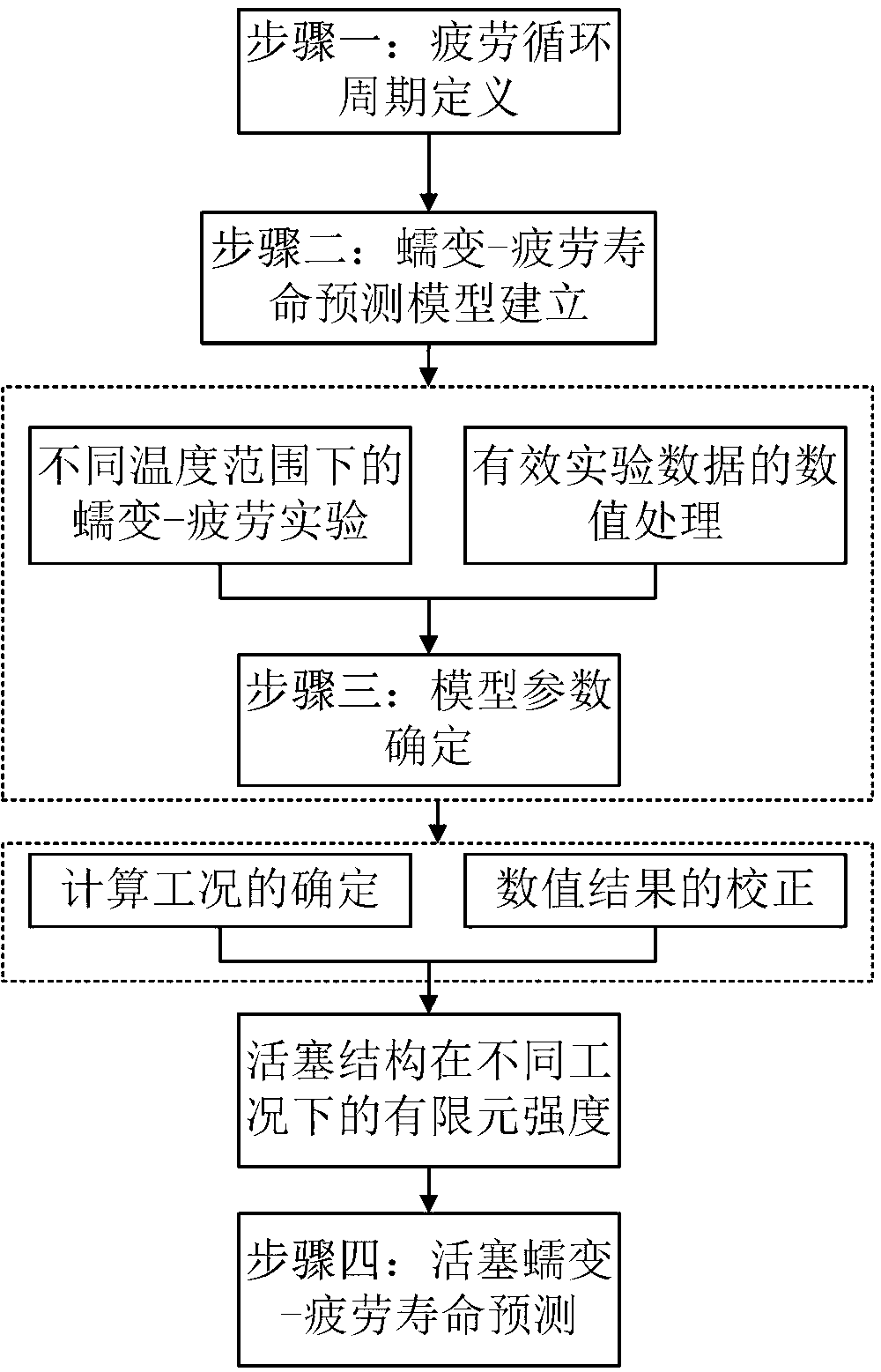

Method used

Image

Examples

Embodiment Construction

[0045] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

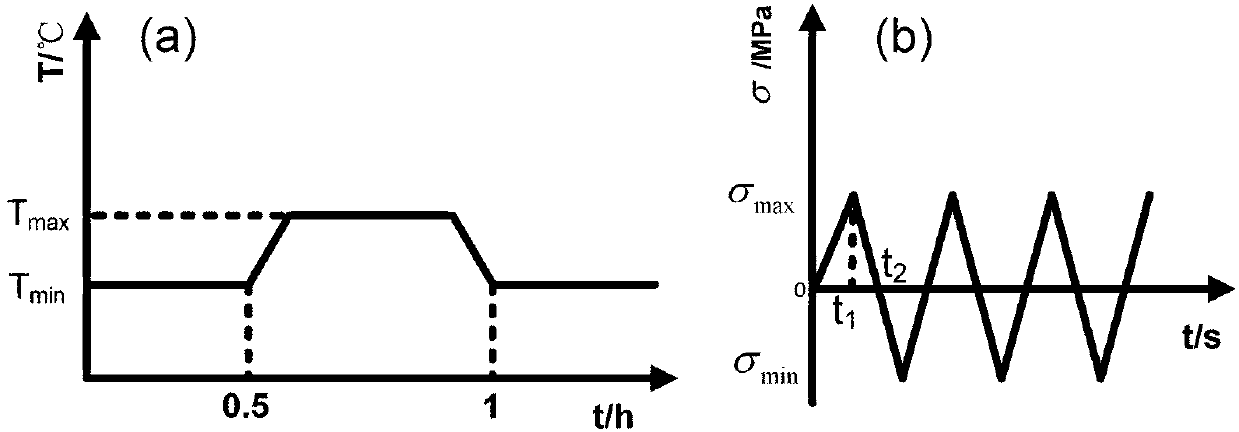

[0046] Due to the long-term and variable working conditions of the vehicle diesel engine, the structural parts of the combustion chamber are subjected to thermal and mechanical loads that change with the engine's working conditions. To predict the creep-fatigue life under this cyclic load feature, the fatigue cycle must first be determined. load. The fatigue cycle load form of the defined high-power diesel engine under changing operating conditions is as follows: figure 2 As shown, the horizontal axis is time, and the vertical axis is temperature and cyclic mechanical stress, respectively.

[0047] The creep damage evolution equation of the material under the above fatigue load characteristics can be expressed as:

[0048] dD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com