A kind of workability index tester and test method of asphalt mixture

A technology of asphalt mixture and tester, which is applied in the direction of instruments, flow characteristics, measuring devices, etc., can solve the problems of unfavorable popularization and application, high manufacturing cost, complicated design, etc., and achieve wide applicability, low manufacturing cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

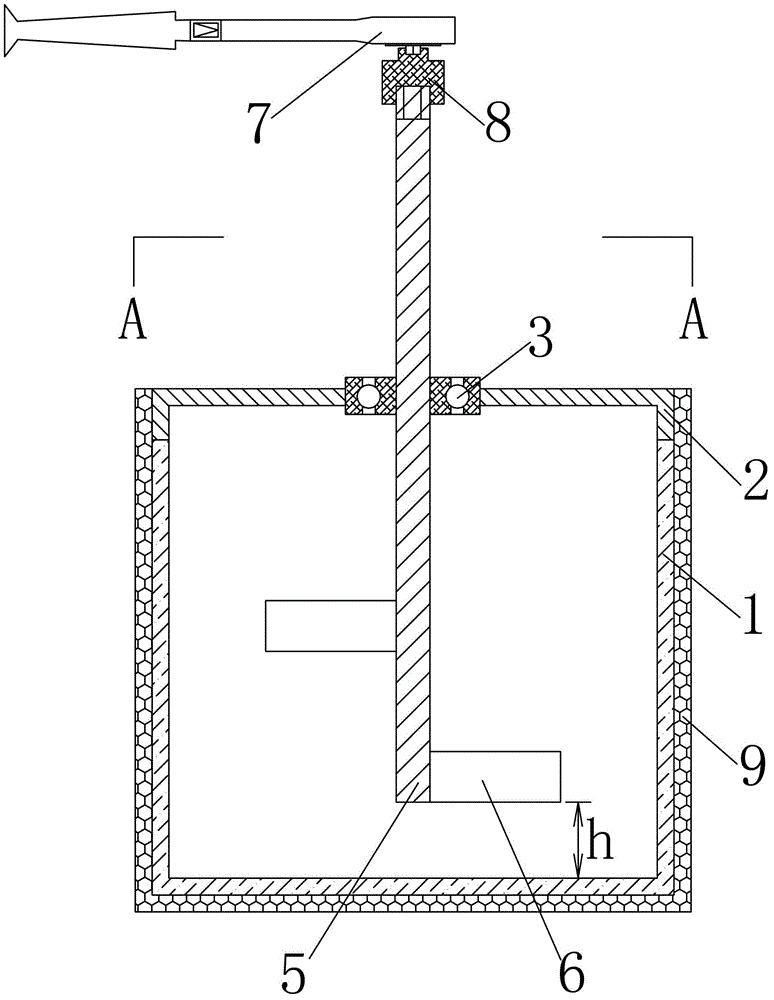

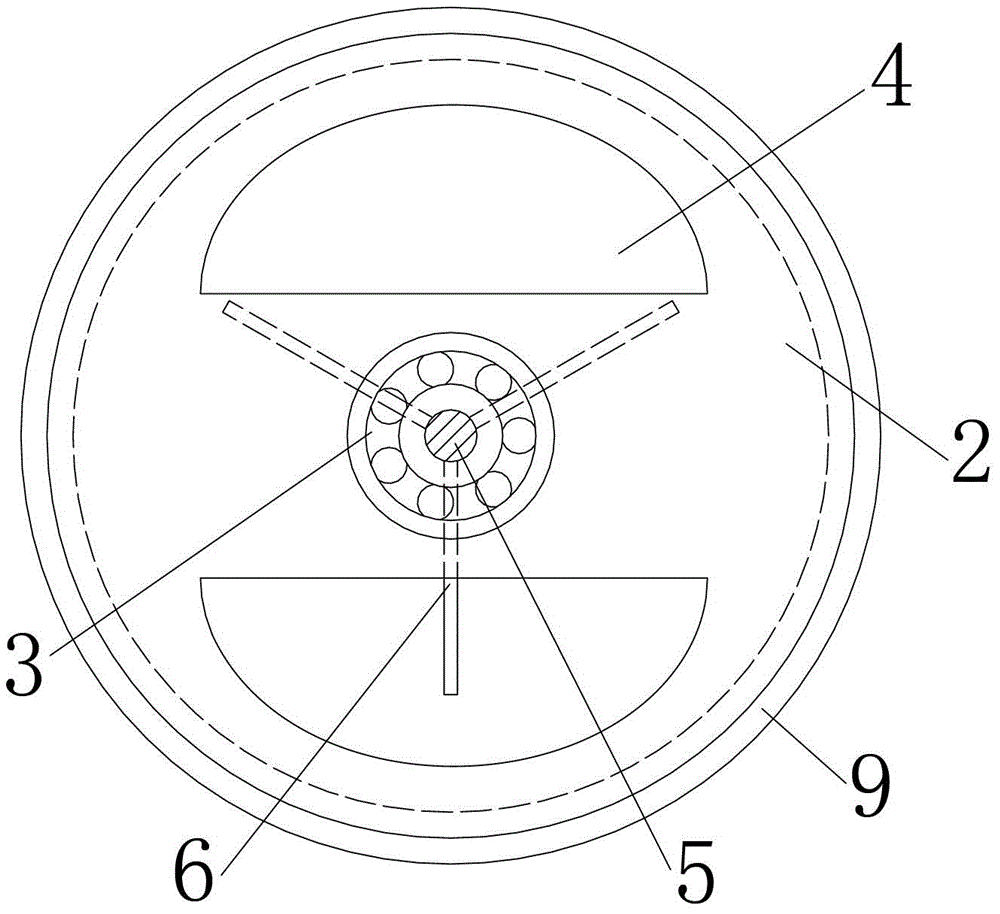

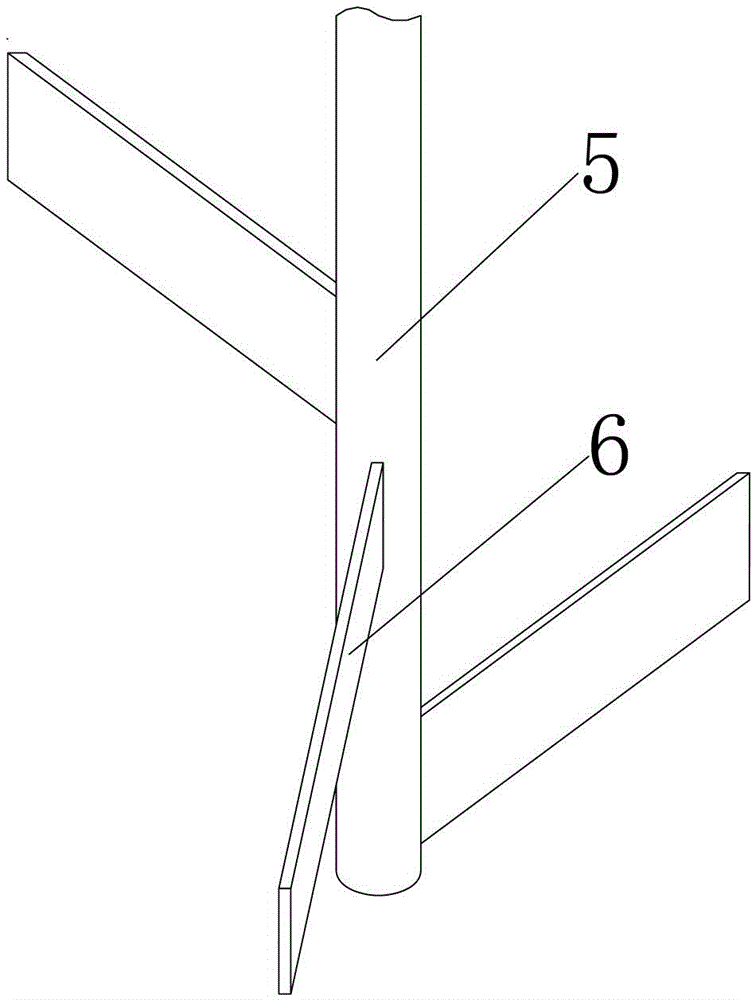

[0033] Such as figure 1 , figure 2 with image 3 As shown, the asphalt mixture and workability index tester of this embodiment includes a bucket 1, a mixing shaft 5, and a torque wrench 7. The top of the bucket 1 is provided with a bucket cover 2, and the bucket cover 2 is provided with a feeding port 4. The stirring shaft 5 is rotatably connected with the barrel cover 2 through a bearing 3, the upper end of the stirring shaft 5 is connected with a torque wrench 7 through a conversion joint 8, and the lower end of the stirring shaft 5 penetrates the barrel cover 2 and extends into the barrel 1 A mixing blade 6 is installed at the lower end of the mixing shaft 5; the torque wrench 7 is a digital torque wrench or a pointer type torque wrench.

[0034] In this embodiment, the bearing 3 is an open deep groove ball bearing. The inner diameter of the bearing 3 is 20 mm, and the outer diameter of the bearing 3 is 52 mm. The conversion joint 8 is an inner hexagon socket joint, and the...

Embodiment 2

[0043] The asphalt mixture and the workability index tester of this example are the same as those of Example 1.

[0044] The method of using the asphalt mixture and workability index tester of this embodiment to test the workability index of the asphalt mixture is the same as in Example 1, except that the asphalt mixture is AC-13 SBS modified Asphalt mixture.

[0045] The workability index K data of the asphalt mixture measured by the asphalt mixture and workability index tester of this embodiment are shown in Table 1.

[0046] Table 1 Test results of workability index K of asphalt mixtures of Example 1 and Example 2 of the present invention

[0047]

[0048] It can be seen from Table 1 that the workability index of the AC-13 base asphalt mixture measured in Example 1 and the workability index of the AC-13 SBS modified asphalt mixture measured in Example 2 all increase with temperature And under the same test temperature and test conditions, the workability index of the AC-13 type SB...

Embodiment 3

[0050] The asphalt mixture and workability index tester of this embodiment is the same as that of embodiment 1, except that the inner diameter of the bearing 3 is 25 mm, and the outer diameter of the bearing 3 is 72 mm. The inner diameter of the barrel 1 is 300 mm, and the depth of the barrel 1 is 300 mm. The number of the mixing blades 6 is three, and the three mixing blades 6 are arranged equidistantly along the axial direction of the mixing shaft 5, and the distance between two adjacent mixing blades 6 is 50 mm. The shape of the stirring blade 6 is rectangular parallelepiped, and the length of the stirring blade 6 is 100 mm, the width is 40 mm, and the thickness is 5 mm. The distance h between the bottom end of the mixing blade near the bottom of the bucket 1 and the bottom of the bucket 1 among the three mixing blades 6 is 50 mm.

[0051] The method for testing the workability index of the asphalt mixture by using the asphalt mixture and workability index tester of this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com