Distribution box

A technology for distribution boxes and electrical appliances, which is applied to electrical components, substation/switch layout details, busbar/line layout, etc. Interior simplicity, light weight, and safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

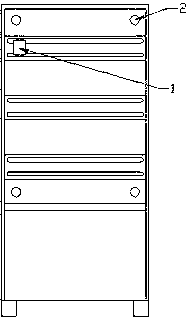

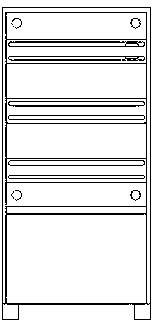

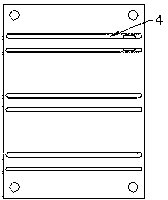

[0022] Such as Figure 1~4 As shown, the distribution box includes a box body and an electrical component installation guide rail, a frame plate, and a pressure plate installed in the box body. The mounting holes 2 at the four corners of the frame plate and the crimping plate are mutually tightened and fixed on the outer shell. There are several wire holes 4 corresponding to the electrical component installation guide rails on the frame plate. The electrical component 1 is installed on the electrical component installation guide rail. On the top, the connected wires pass through the wire hole 4, and are finally buried in the outer embossment 3 on the pressure plate, and finally lead out to the main outlet hole of the distribution box. The outer embossment 3 of the pressure plate is made of aluminum alloy The board is made by mechanical stamping, and like the frame board, it is covered by electrostatic spraying process, which is more beautiful and insulating at the same time, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com