Integrated adsorption separation device for small-sized oxygenerator

An adsorption separation and oxygen generator technology, applied in the field of oxygen generators, can solve the problems of inconvenient installation, too many accessories, and large internal space of oxygen generators, and achieve the effects of convenient installation, reduced safety hazards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

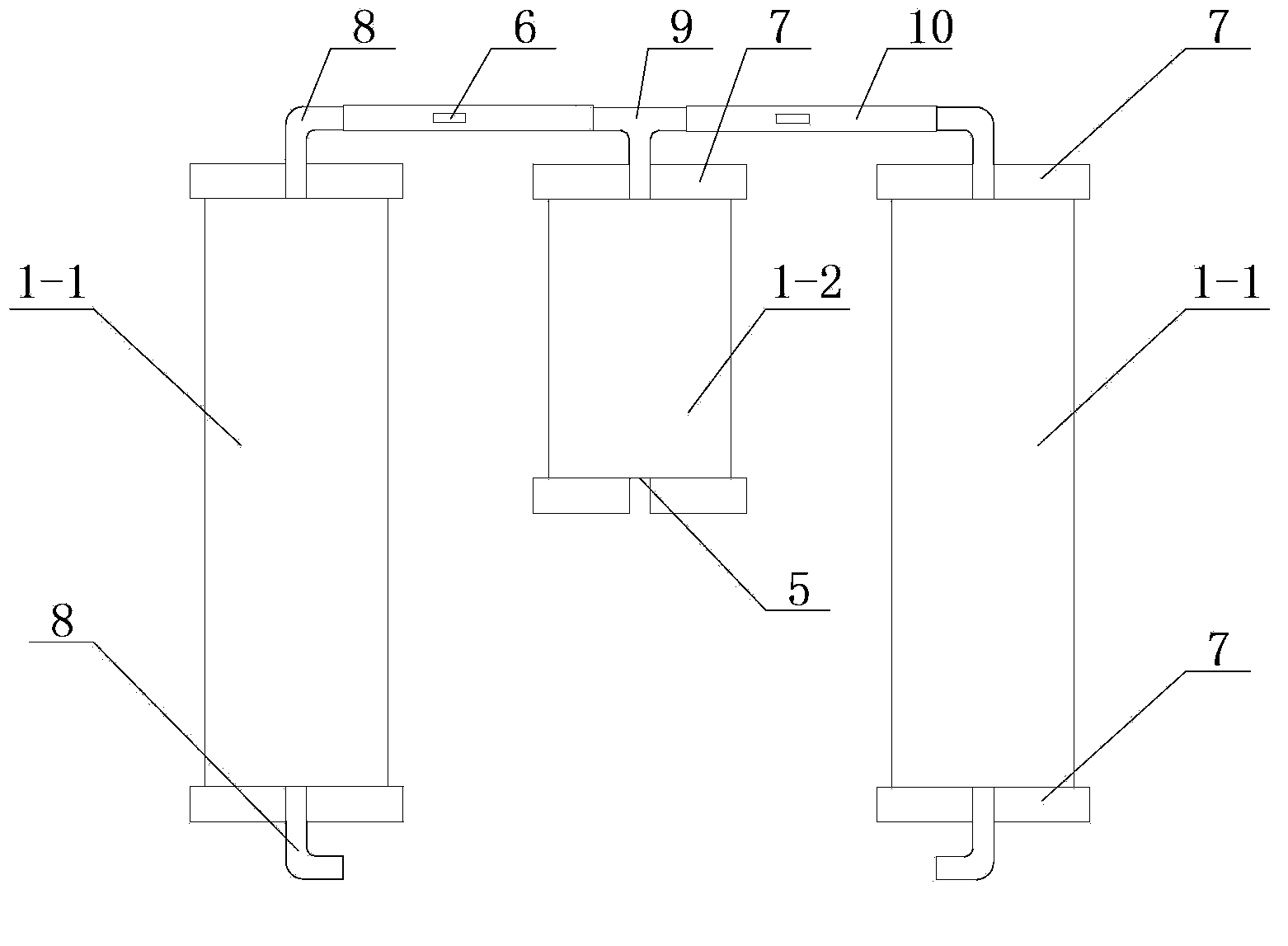

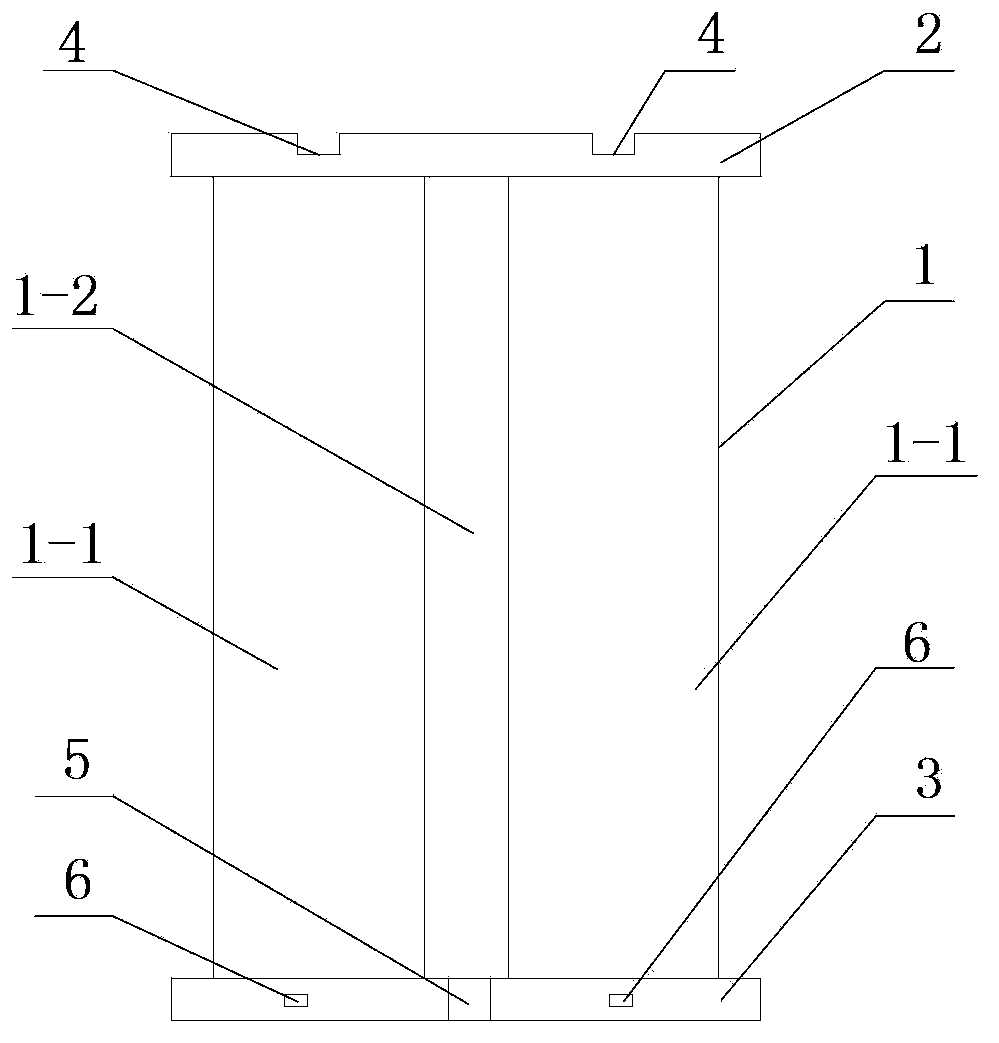

[0013] as attached figure 2 The shown integrated adsorption and separation device for small oxygen generators includes a device body 1 with an integrated structure. The device body 1 has two adsorption towers 1-1 and an oxygen storage tower 1-1 between the two adsorption towers 1-1. 2. The upper end surface of the device body 1 is provided with an upper end cover 2, and the lower end surface of the device body 1 is provided with a lower end cover 3; the upper end cover 2 is provided with two openings 4 for air entry or nitrogen discharge; the lower end cover 3 is provided with There is an oxygen outlet 5.

[0014] Two throttling bridges 6 located on both sides of the oxygen outlet 5 are also arranged on the lower end cover 3 .

[0015] In specific use, the two openings 4 provided on the upper end cover 2 will be connected with the corresponding interfaces on the electromagnetic valve to realize the separation function of oxygen and nitrogen. The oxygen output port 5 provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com