Horizontal type adjustable rubbing and scrubbing machine

An adjustable, scrubbing machine technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problem that the filling degree and pressing force of sheet materials cannot be adjusted, and sewage and dirt cannot be effectively separated. , friction and incomplete cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

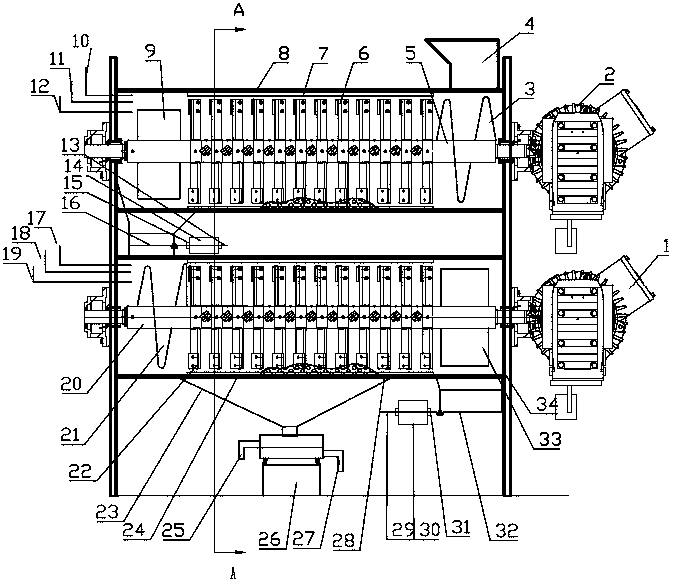

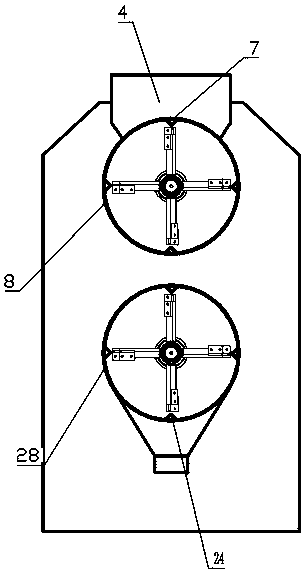

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

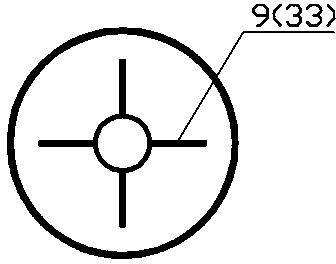

[0017] like figure 1 , figure 2 and image 3 As shown, the present invention includes frame 34, speed reducer, rotating shaft, cylinder body, slag collecting tank 23 and vibrating screen 26 among the present embodiment; The top of described frame 34 is provided with feed hopper 4; Described deceleration There are two machines, respectively a speed reducer 1 and a speed reducer 2, which are arranged on the side wall of the frame 34, and there are also two rotating shafts, which are respectively rotating shaft 5 and rotating shaft 20; the cylinder body also has two, Respectively, the upper cylinder 8 and the lower cylinder 28, the upper cylinder 8 and the lower cylinder 28 are placed horizontally, which include a feeding section, a friction scrubbing section, and a discharge section; the rotating shaft 5 runs through the upper cylinder 8 transversely and The reducer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com