Automatic charging system

An automatic charging and automatic technology, applied in liquid filling, barrel/barrel filling, etc., can solve problems such as difficulty in accurately controlling the weight of material liquid, leakage of finished material liquid, material loss, etc., to avoid material loss and improve work efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

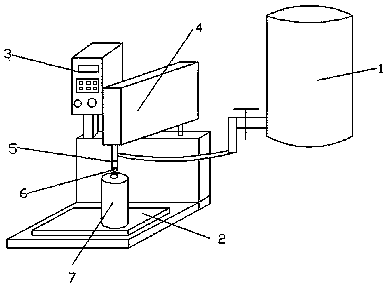

[0010] The technical scheme and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

[0011] Such as figure 1 As shown, the present invention comprises reactor 1 and automatic charging device, and automatic charging device comprises automatic scale 2, is connected with control box 3 on the automatic scale 2, is connected with flow control device 4 on the control box 3, in the flow control device 4 A flow control valve 5 is set, and a weight controller is set in the control box. When the weight of the finished material liquid in the upper loading barrel 6 of the automatic scale 2 is close to the weight value set in advance in the control box 3, the weight control in the control box 3 The device will transmit a signal to the flow control device 4, and the flow control device 4 can adjust the flow control valve 5 according to the signal, which can gradually red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com