A telescopic structural unit and a telescopic rod composed of the structural unit

A telescopic structure and telescopic rod technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of complicated operation, explosive cylinder, high safety, etc., and achieve the effect of simple operation, low safety hazard, and reduced safety hazard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

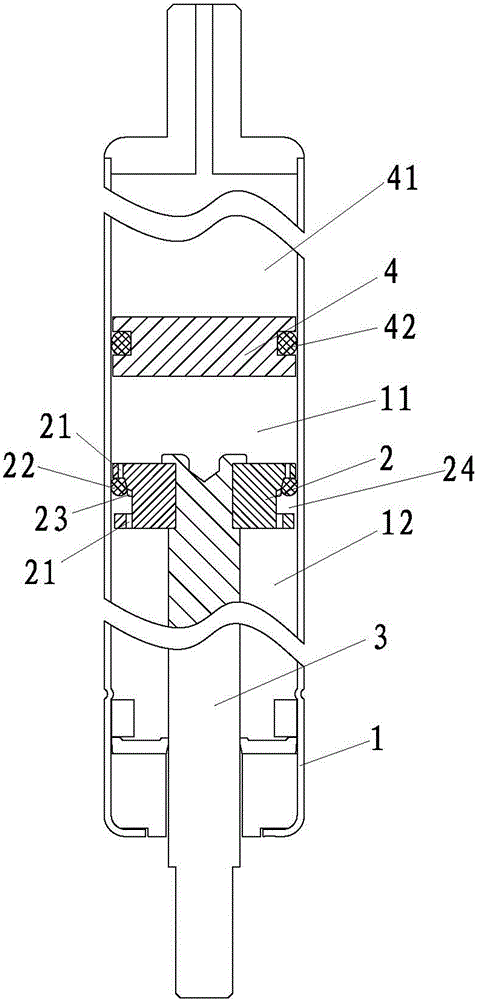

[0036]Embodiment 1: A telescopic structural unit that enables the piston rod to be relatively fixed relative to the cylinder in the original moving direction of the piston rod by increasing the pulling force or increasing the pulling speed, such as Figure 1-3 As shown, including the cylinder body 1, the cylinder body 1 is provided with a floating piston 4 that is sealed and slidably connected with the inner wall of the cylinder body 1 through the first sealing ring 42, and the floating piston 4 divides the cylinder body 1 into an exhaust chamber 41 that communicates with the atmosphere and A liquid chamber that is sealed and filled with liquid. The valve body 2 is arranged in the liquid chamber. The valve body 2 divides the liquid chamber into a liquid chamber 11 and a liquid chamber 2 12, and the liquid chamber 11 is located between the liquid chamber 12 and the exhaust chamber 41 between; the valve body 2 is fixed with a piston rod 3, and the piston rod 3 extends to the outs...

Embodiment 2

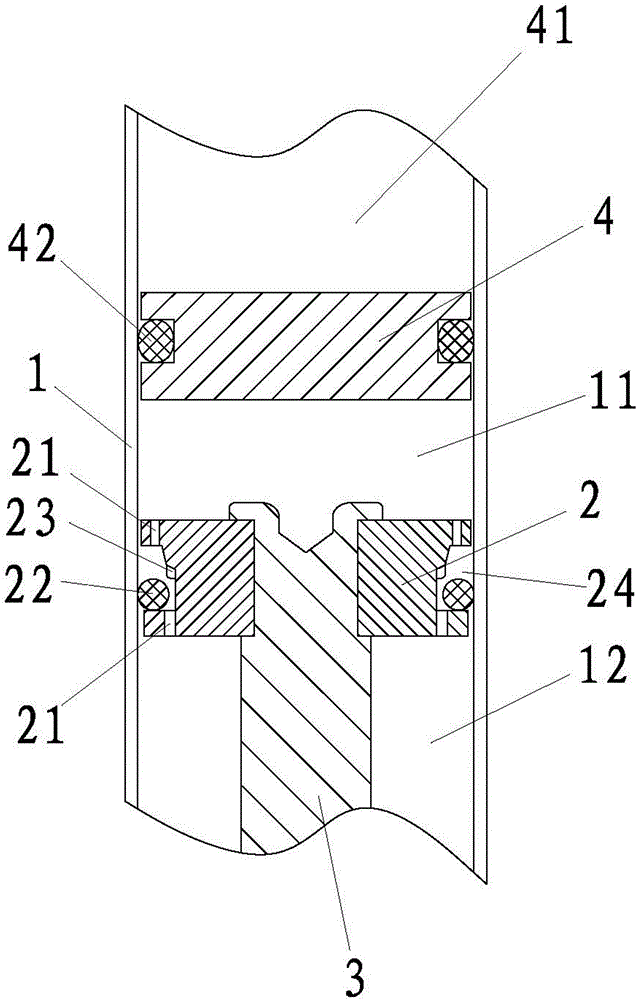

[0042] Embodiment 2: The difference with Embodiment 1 is that, as Figure 4 As shown, the resistance member 23 is a step that reflects the change of the outer diameter of the inner wall of the flow chamber 24. In order to facilitate the flow of the liquid in the first liquid chamber 11 and the second liquid chamber 12 when the sealing member 22 is in contact with the resistance member 23, at the step There should be a groove for easy circulation, the groove is not shown in the figure.

Embodiment 3

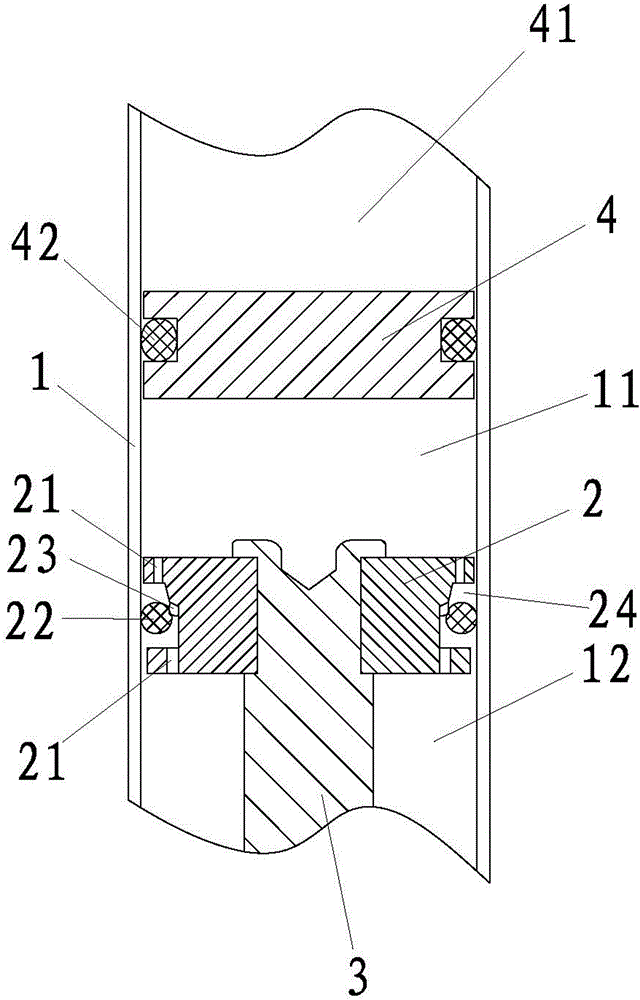

[0043] Embodiment 3: The difference with Embodiment 1 is that, as Figure 5 As shown, the channel 21 communicates with two openings of the flow chamber 24 , wherein the opening closer to the second liquid chamber 12 is disposed on the inner side wall of the flow chamber 24 .

[0044] As an option, the channel 21 communicates with the two openings of the flow chamber 24, and the opening closer to the liquid chamber 11 can also be arranged on the inner side wall of the flow chamber 24, as long as the opening can be closed by the sealing member 22. For this purpose, the position change of this opening is not shown in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com