Method for machining magnetic yoke applicable to electromagnetic clutch

An electromagnetic clutch and processing method technology, applied in the field of magnetic yokes, can solve the problems of poor rigidity of magnetic yokes, magnetic flux leakage, etc., and achieve the effects of enhanced rigidity, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings.

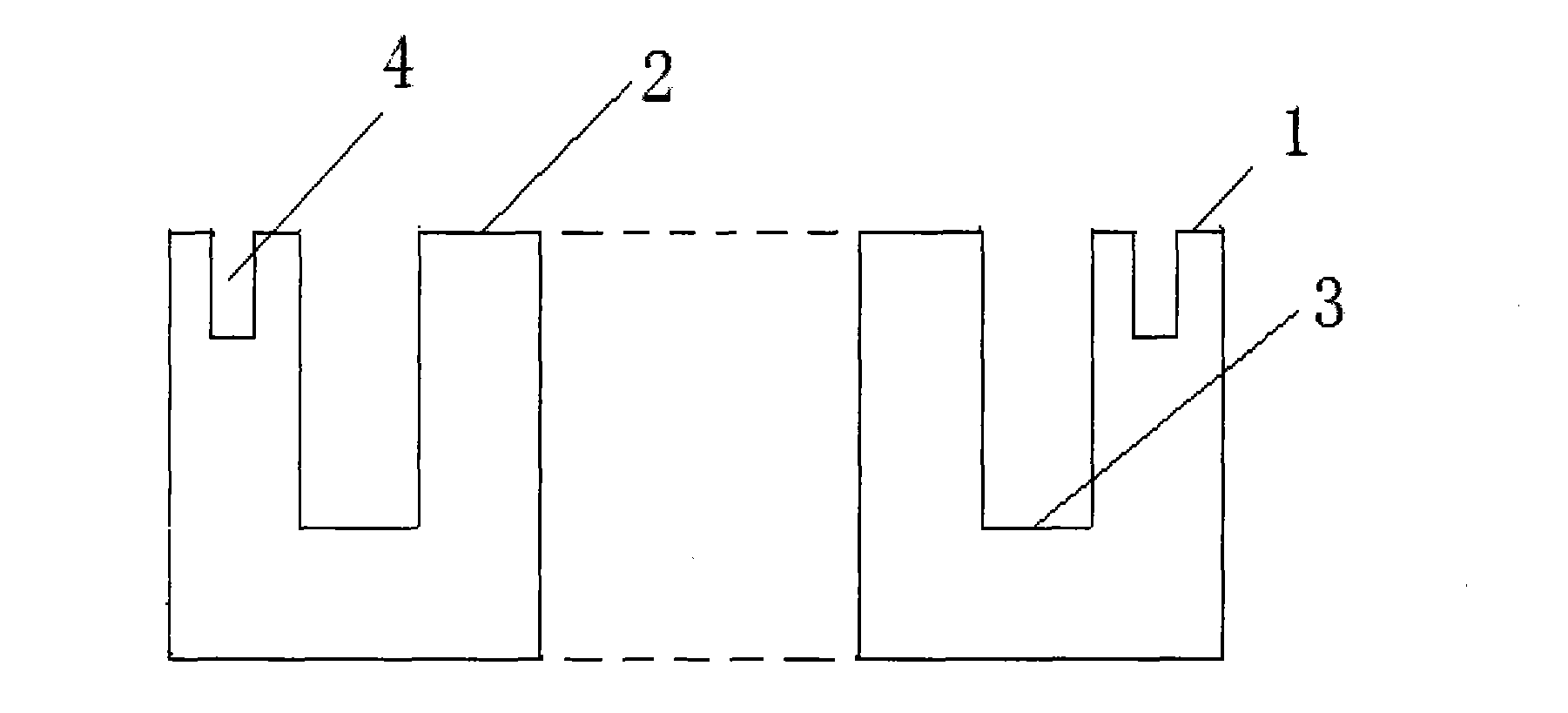

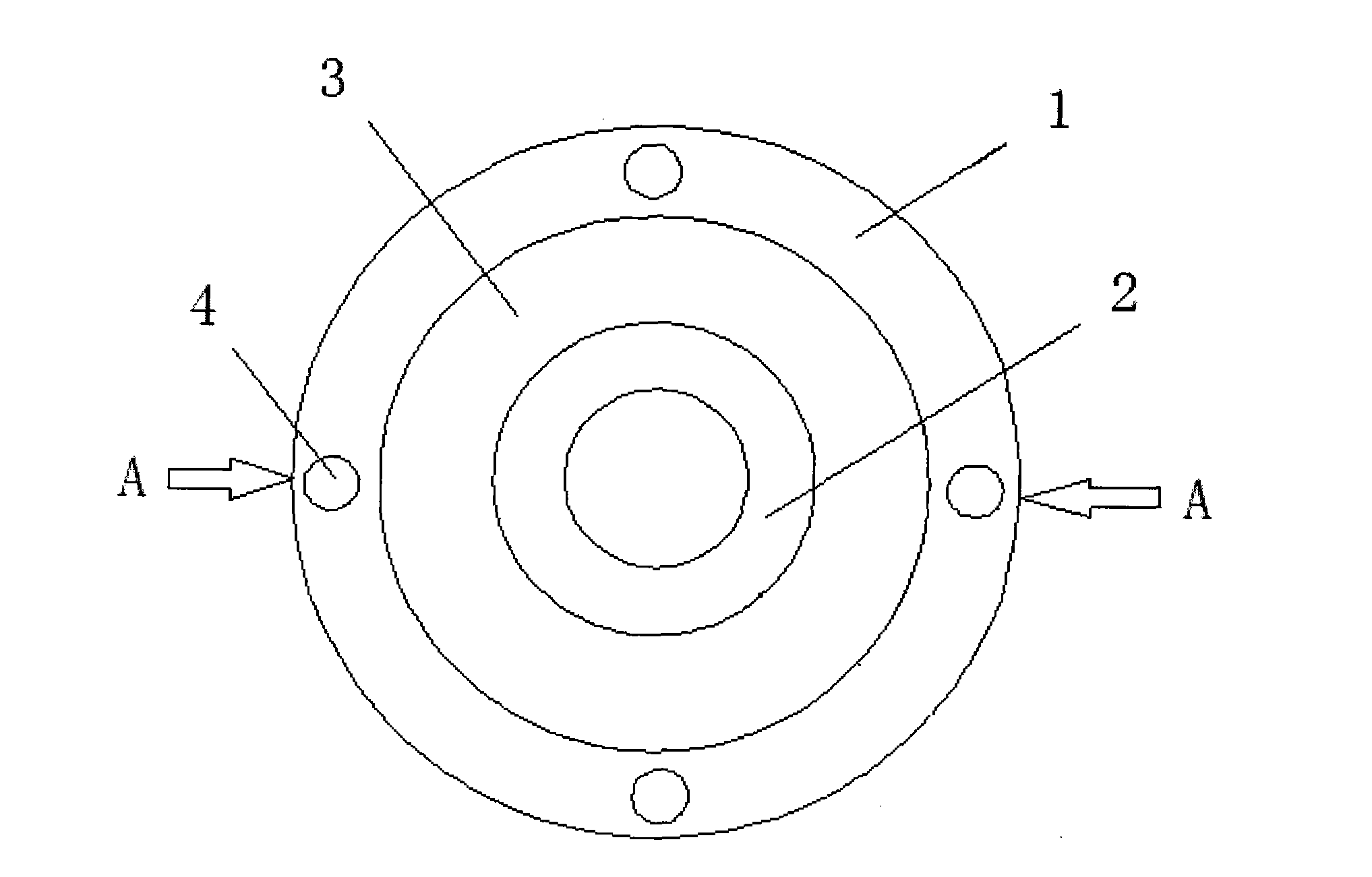

[0014] A processing method suitable for a magnetic yoke of an electromagnetic clutch includes an outer ring 1, an inner ring 2, a bottom pad 3 and a connecting hole 4, and is characterized in that the outer ring 1 and the inner ring 2 are concentric circles and the heights of the two are equal, and the connecting hole 4 is set on the outer ring 1 . The outer ring 1 has an inner diameter of 95mm and an outer diameter of 155mm, the inner ring 2 has an inner diameter of 52mm and an outer diameter of 65mm, and the number of connecting holes 4 is 4, with a diameter of is 10.5mm. The outer ring 1, the inner ring 2 and the bottom pad 3 are formed by one-time punching with cylindrical steel cake material, which increases the sealing performance between the parts of the yoke, improves the performance of the product, and prolongs the service life.

[0015] Various modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com