Pressure Adaptive Low Frequency Broadband Elastic Resonance Muffler

A muffler device, self-adaptive technology, applied in low frequency muffler. It can solve the problems of difficult low-frequency broadband noise reduction, poor compressibility, difficult low-frequency noise reduction, etc., to achieve the effect of increasing the bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

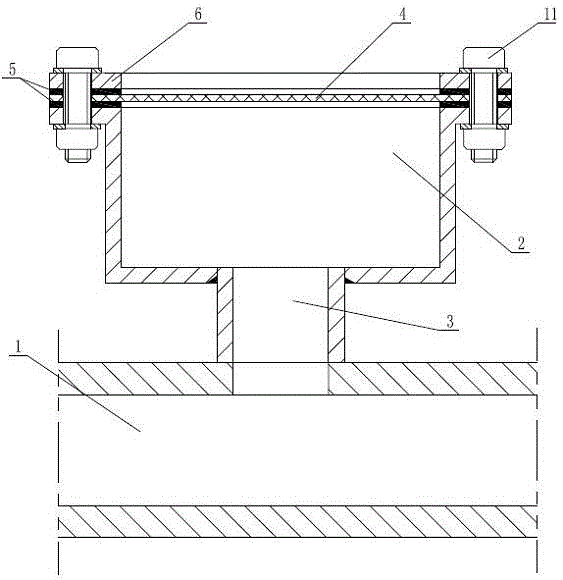

[0026] See figure 1 , the other side of the elastic wall plate 4 is sealed and connected with a pressure ring 6 through the gasket 5, and the elastic wall plate 4, the gasket 5, the pressure ring 6 and the flange part 21 of the cavity 2 are connected by bolts 11, nuts and washers Components are tightly connected. The noise reduction device of this embodiment is suitable for the situation that the pressure of the liquid pipeline 1 is normal pressure or the pressure is relatively low. At this time, it is determined according to the thickness of the elastic wall plate 4 whether it meets the pressure requirement of the liquid pipeline 1. , the sealing gasket 5 and the elastic wall plate 4 can be fixed on the cavity 2 only with the pressure ring 6, and water leakage (other liquids) can be prevented at the same time.

no. 2 example

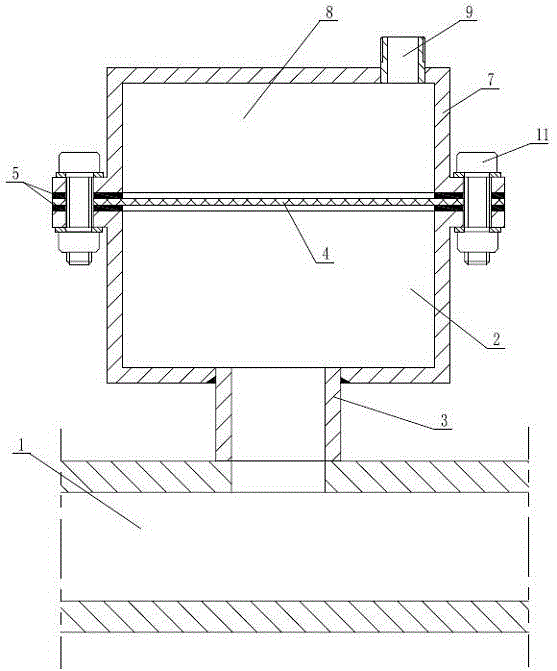

[0028] See figure 2 , the other side of the elastic wall plate 4 is sealed and connected with a hollow shell 7 through a gasket 5, and a back pressure chamber 8 is arranged in the hollow shell 7, and the back pressure chamber 8 is facing the cavity body 2, and the back pressure chamber 8 The hollow shell 7 on the side away from the elastic wall plate 4 is provided with a through hole 9, the through hole 9 is a vent hole, and the end of the hollow shell 7 facing the elastic wall plate 4 has a flange part 71, the elastic The wall plate 4 , the gasket 5 , the flange portion 71 of the hollow shell 7 and the flange portion 21 of the cavity 2 are tightly connected by bolts 11 , nuts and washers. The noise reduction device of this embodiment is suitable for the situation where the pressure of the liquid pipeline 1 is relatively high. In order to protect the elastic wall plate 4 and prevent it from being crushed, a back pressure chamber 8 is provided on the other side of the elastic ...

no. 3 example

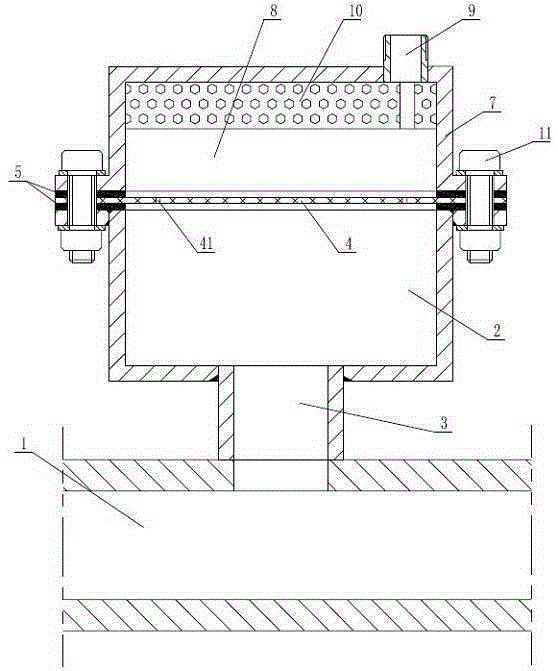

[0030] See image 3 , the other side of the elastic wall plate 4 is sealed and connected with a hollow shell 7 through a gasket 5, the hollow shell 7 is provided with a back pressure chamber 8, the back pressure chamber 8 is facing the cavity body 2, and the back pressure chamber 8 The hollow shell 7 on the side away from the elastic wall plate 4 is provided with a through hole 9, the through hole 9 is the inlet and outlet hole of the liquid, a small number of small holes 41 are arranged on the elastic wall plate 4, the back pressure chamber 8 and the cavity body 2 Connected through the small hole 41, the end of the hollow shell 7 facing the elastic wall plate 4 has a flange portion 71, the elastic wall plate 4, the gasket 5, the flange portion 71 of the hollow shell 7 and the cavity 2 The flange part 21 is fastened and connected by bolts 11, nuts and washers. The muffler device of this embodiment is also applicable to the situation where the pressure of the liquid pipeline 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com