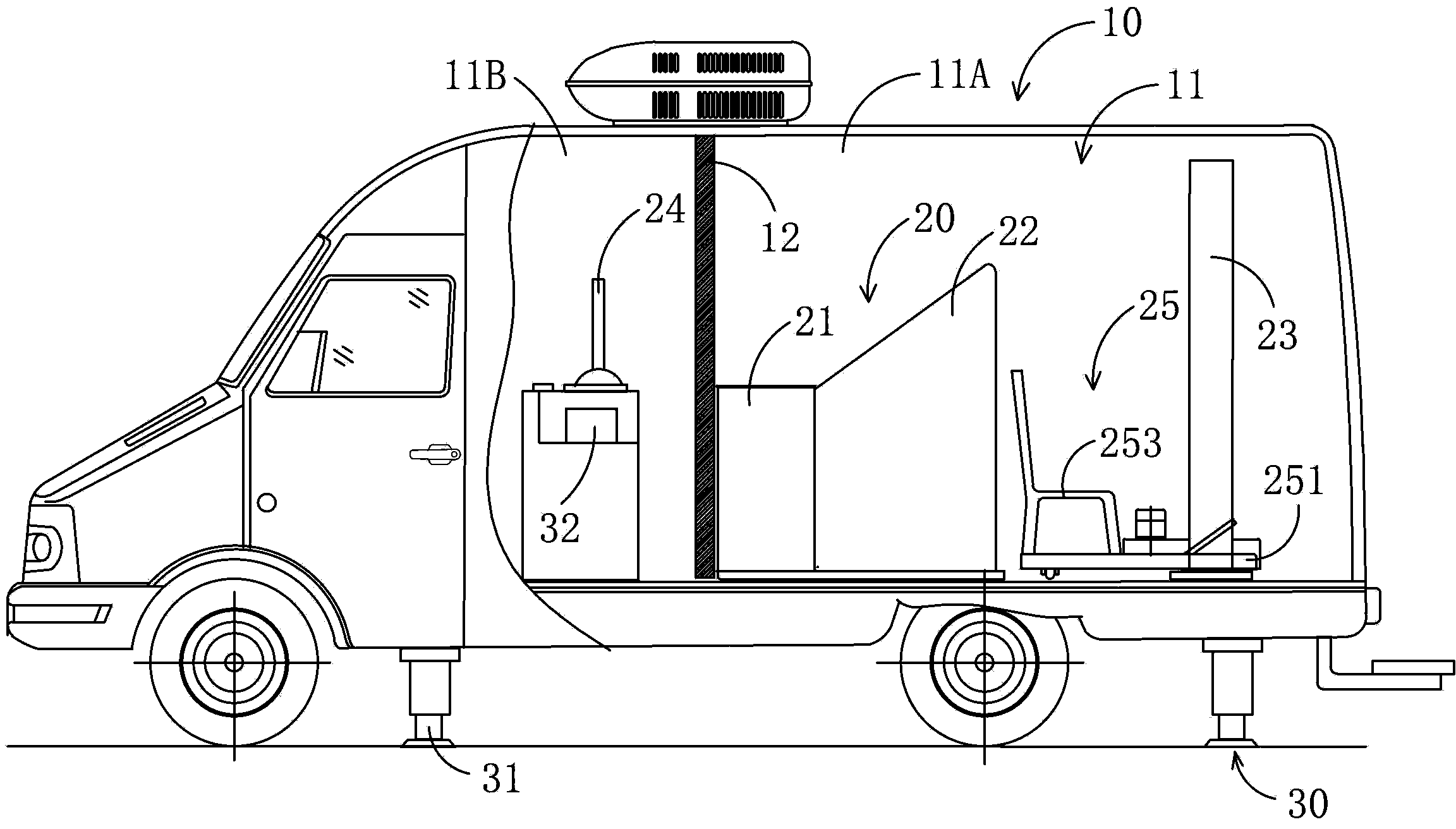

Vehicle-mounted X-ray whole-boy perspective safety check system

A safety inspection and X-ray technology, applied in the field of vehicle-mounted X-ray human body perspective safety inspection system, can solve the problems of being unable to be widely used, failing to meet the installation requirements, and the overall height of the car body exceeding the standard, so as to achieve easy implementation and shorten The effect of high altitude and low radiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

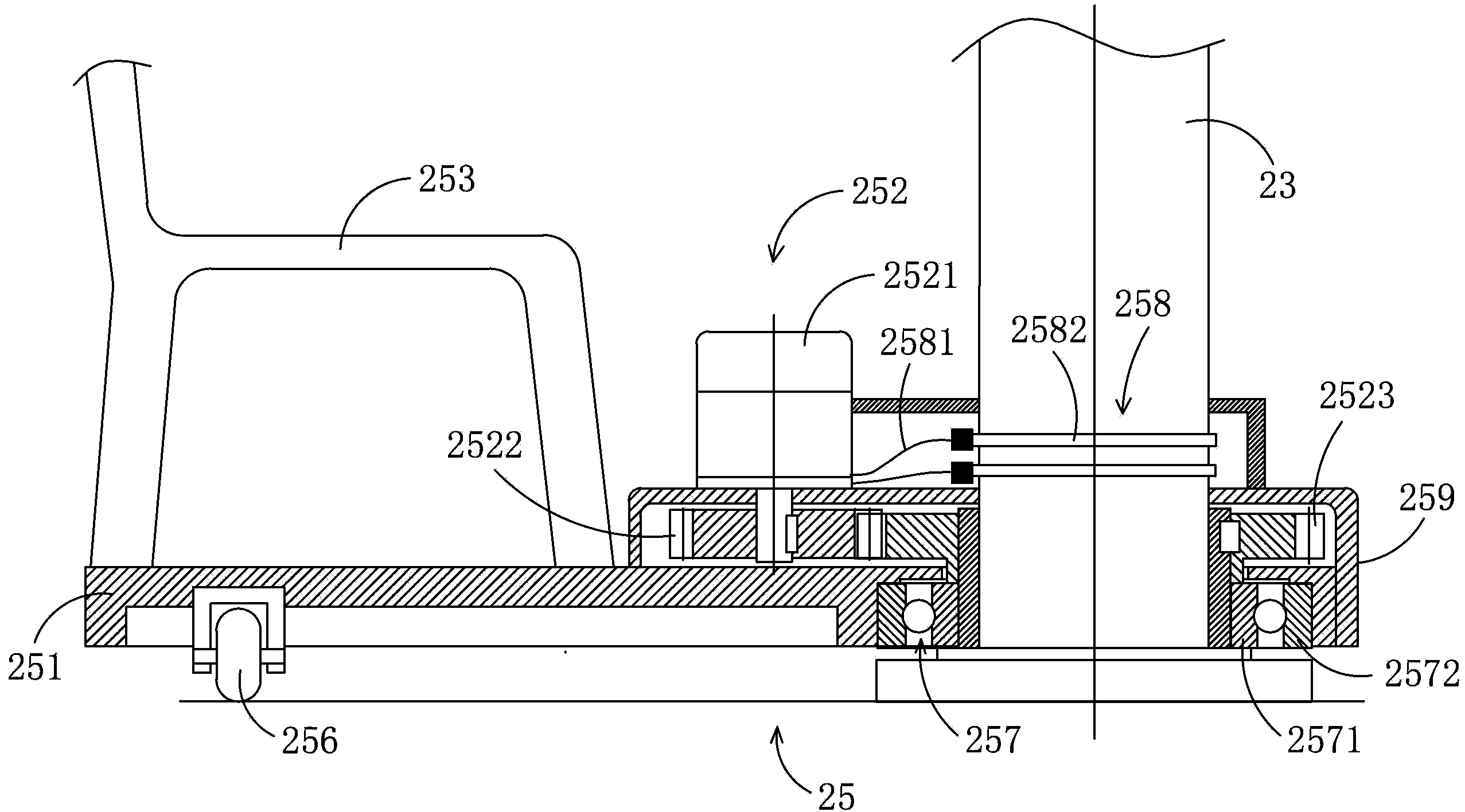

[0030] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the driving device 252, such as Figure 4 As shown, in this embodiment, the driving device 252 is an outer rotor 2524 motor, and the rotor 2524 is sleeved on the periphery of the stator 2525, and the stator 2525 is sleeved on the X-ray detector 23, and is connected to the X-ray detector 23 Fixed connection; the rotor 2524 is fixedly connected to the base 251 . When energized, the rotation of the rotor 2524 directly drives the conveyor table 25 to rotate around the X-ray detector. In this embodiment, the motor of the outer rotor 2524 is used as the driving device 252, and the required torque of the motor of the outer rotor 2524 is relatively large, but its structure is simple and easier to implement.

Embodiment 3

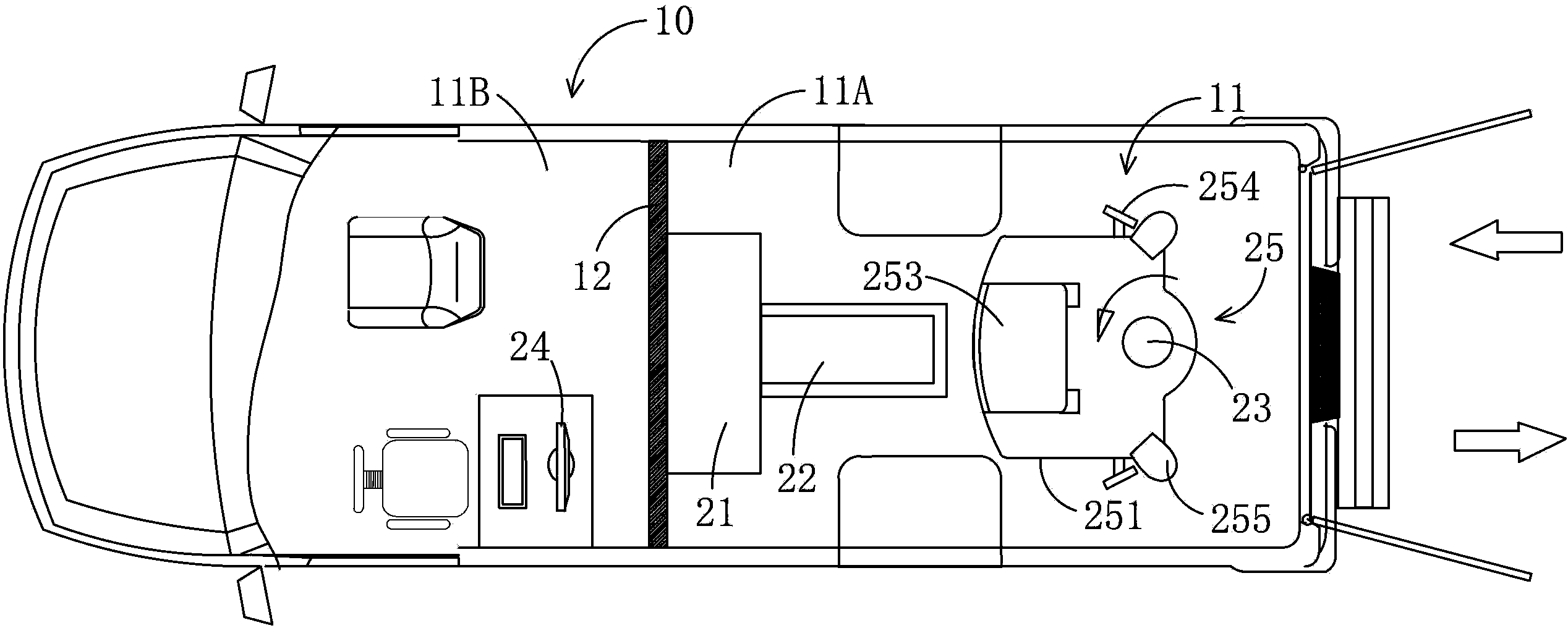

[0032] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 7 , Figure 8 As shown, two seats 253, four armrests 254, and four footrests 255 are arranged on the base 251. Symmetrical; the armrests 254 and the footrests 255 are respectively arranged on the side front of the seat 253 and symmetrically arranged on both sides of the X-ray detector 23 . Of course, the driving device 252 in this embodiment can also be the driving device 252 in the second embodiment. In this embodiment, two seats 253 are provided, which can improve the inspection efficiency. When the previous examinee finishes scanning, the next examinee can directly board the seat corresponding to the former, and then turn into a fan-shaped X-ray. The beam is scanned, which can save the time of the 25 half-circle empty travel of the conveyor table, thereby improving the inspection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com