Golf shoe

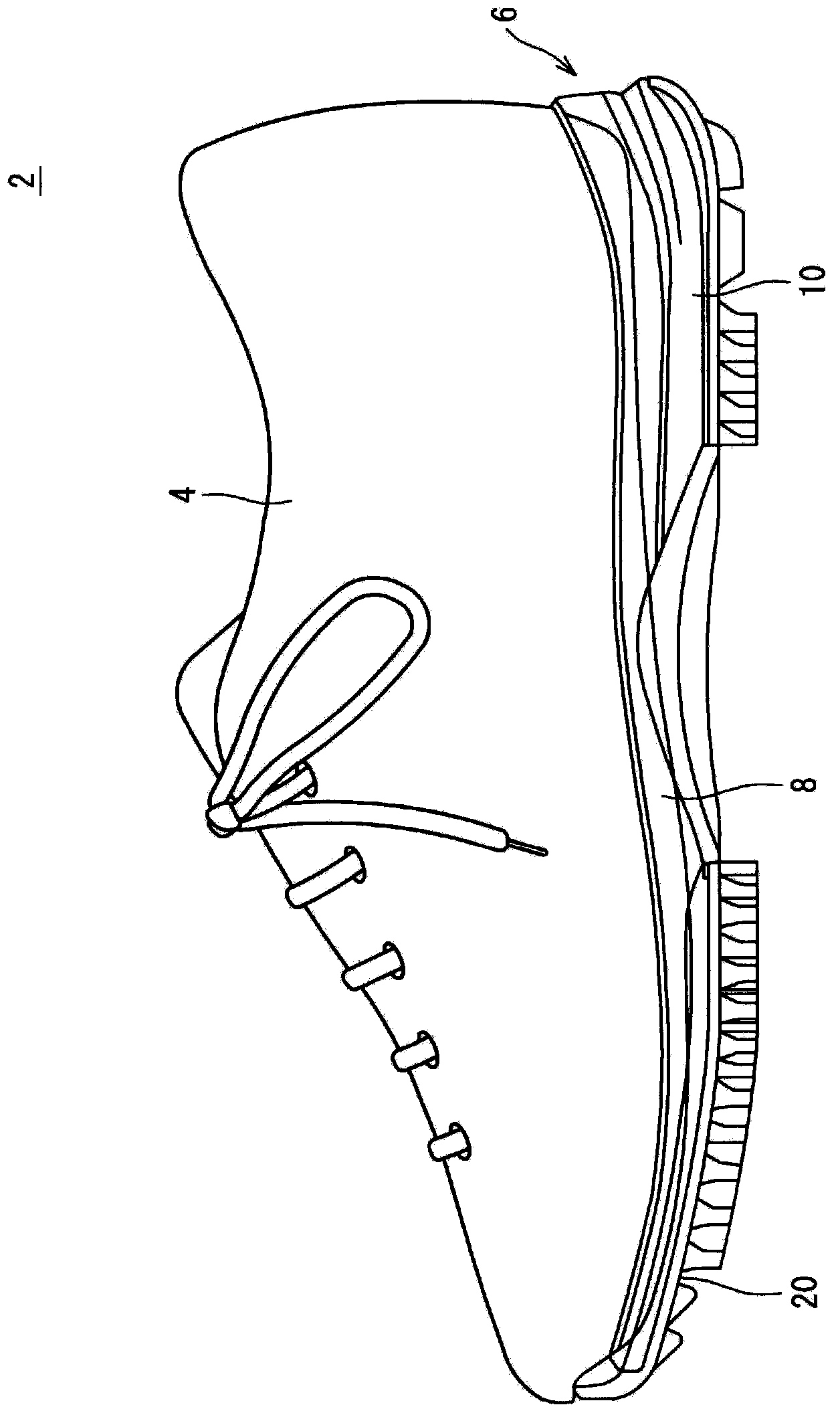

A golf ball and bottom surface technology, applied in the field of golf shoes, can solve the problem of incomplete elimination of the top thorn feeling, and achieve the effect of inhibiting slippage and excellent wearing feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

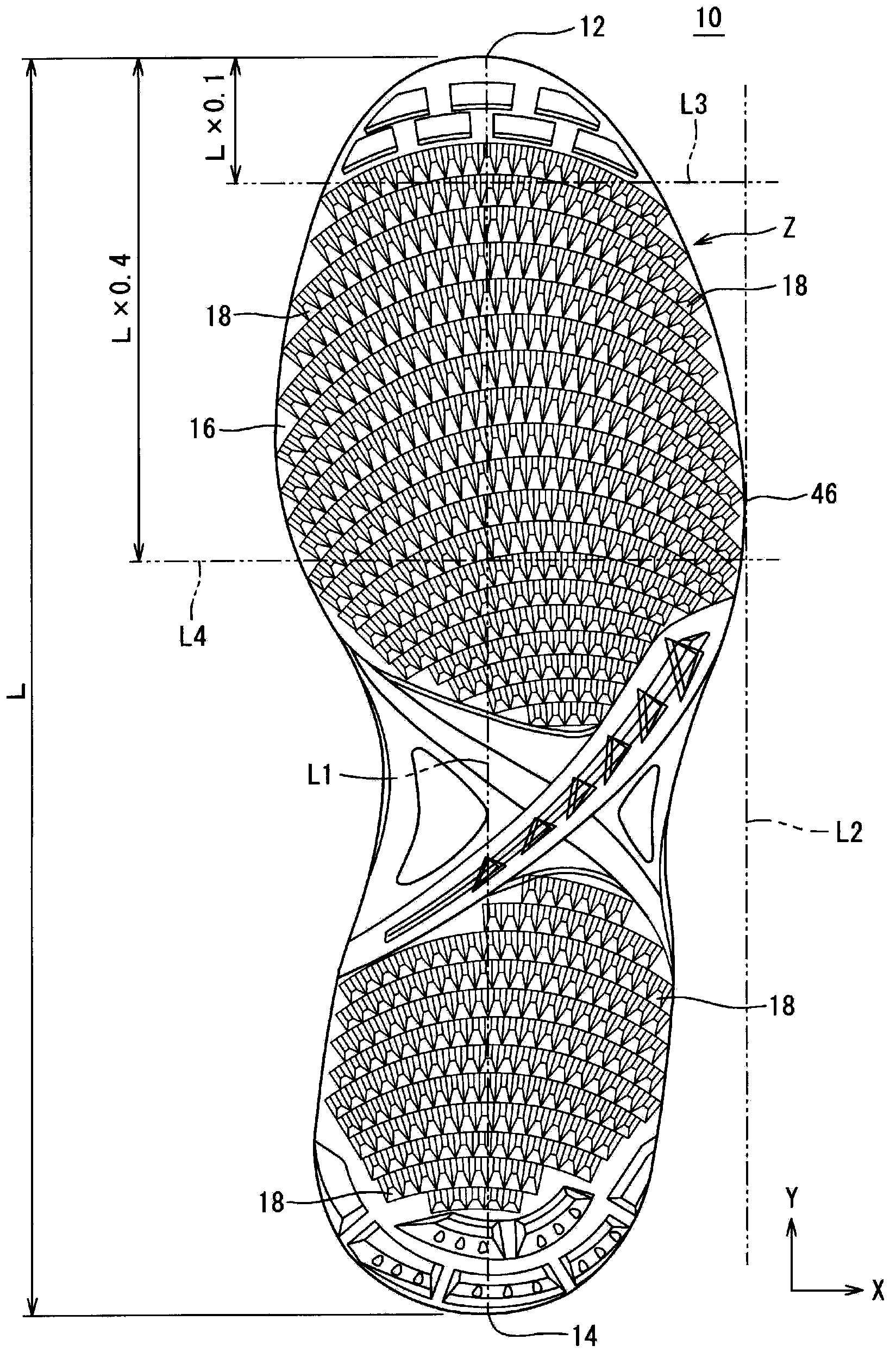

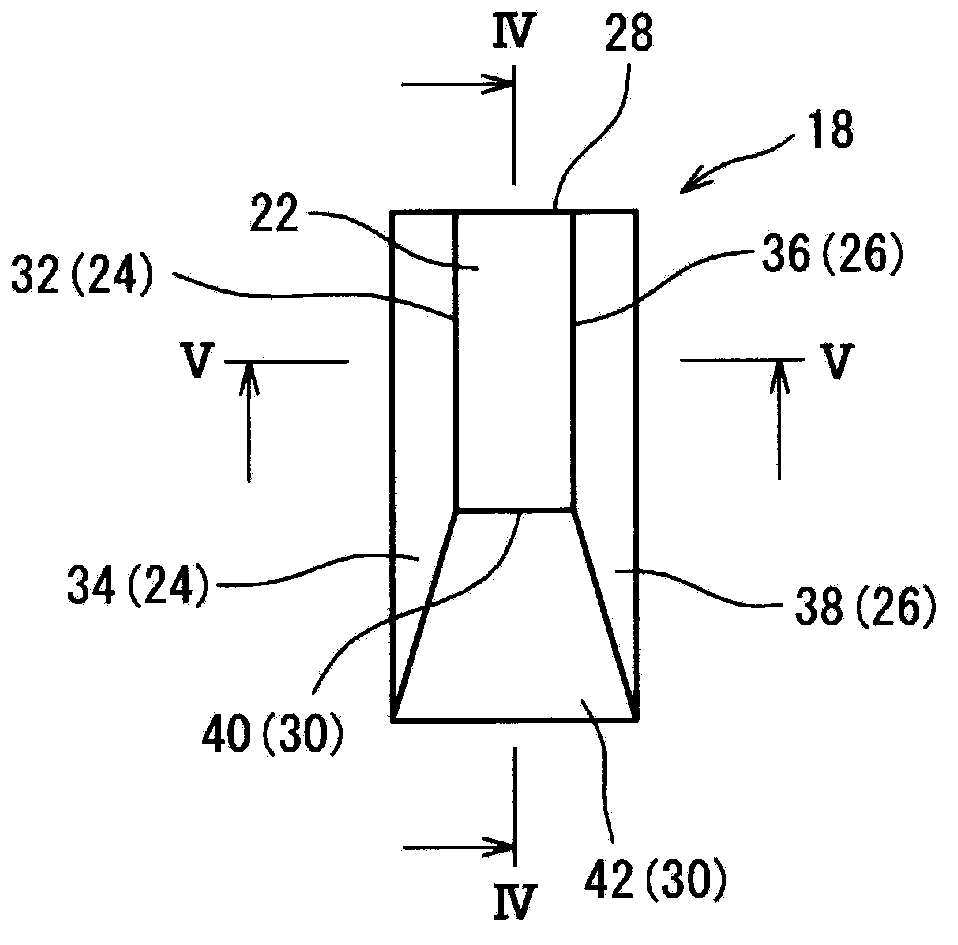

Embodiment 1

[0059] A rubber composition using polybutadiene as a base rubber is injected into a mold. This rubber composition is pressurized and heated to form an outsole having a base and protrusions. The pair of golf shoes of Example 1 was obtained by combining the outer sole, upper, midsole, and inner sole. The pair of golf shoes is composed of a golf shoe for the right foot and a golf shoe for the left foot. In each golf shoe, there are 60 protrusions in the region Z. The area s2 of the ground plane of each protrusion is 4.5mm 2 . In this golf shoe, the area S of the zone Z is 3300mm 2 , the area S1 is 3240mm 2 , the area S2 is 270mm 2 . Therefore, the proportion P1 is 98%, and the proportion P2 is 8%. The hardness of the base and raised Oscar A is 75.

Embodiment 2-4 and comparative example 1

[0061] The area s2 of the ground contact surface was made as shown in Table 1 below, and the others were the same as in Example 1 to obtain golf shoes of Examples 2-4 and Comparative Example 1.

Embodiment 5-7 and comparative example 2

[0063] The number of protrusions was made as shown in Table 2 below, and the others were the same as in Example 1 to obtain golf shoes of Examples 5-7 and Comparative Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com