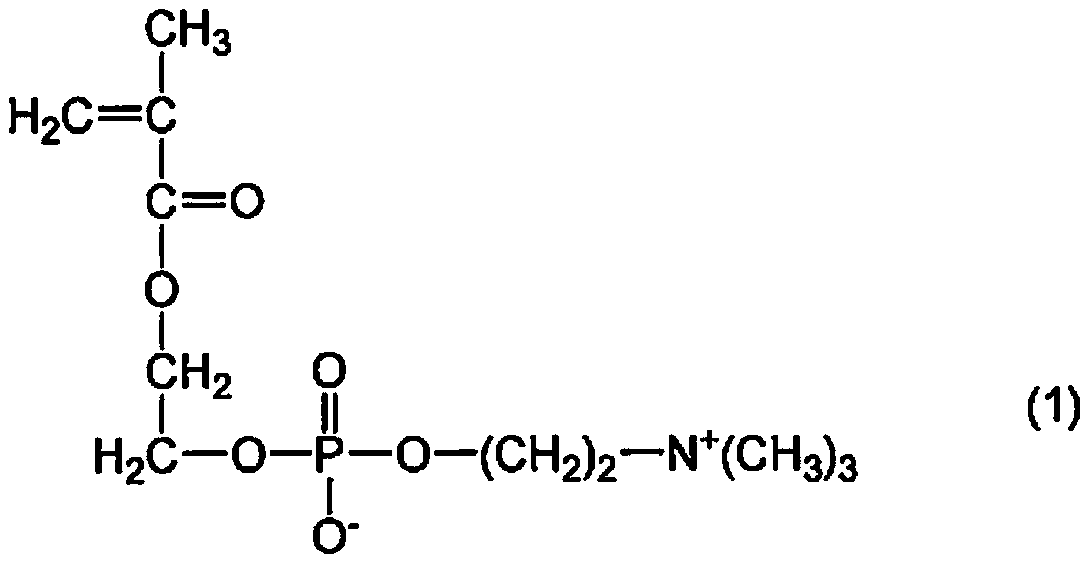

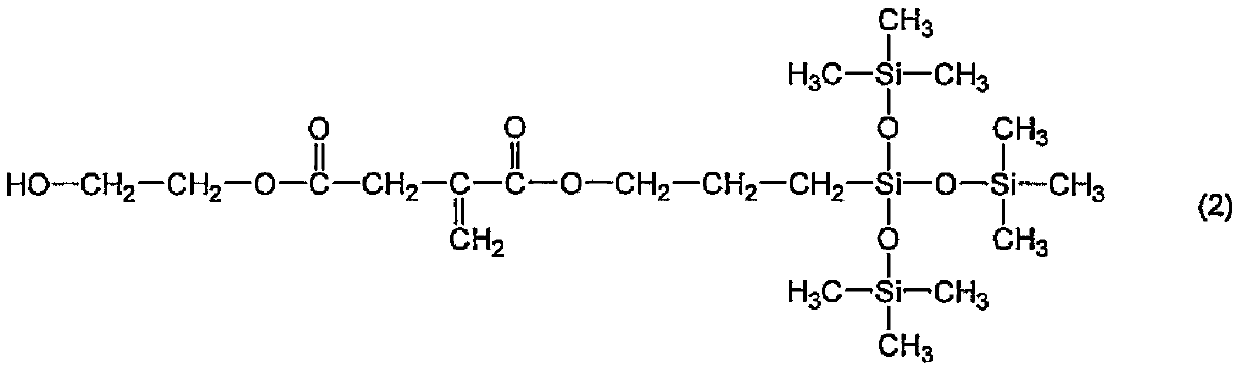

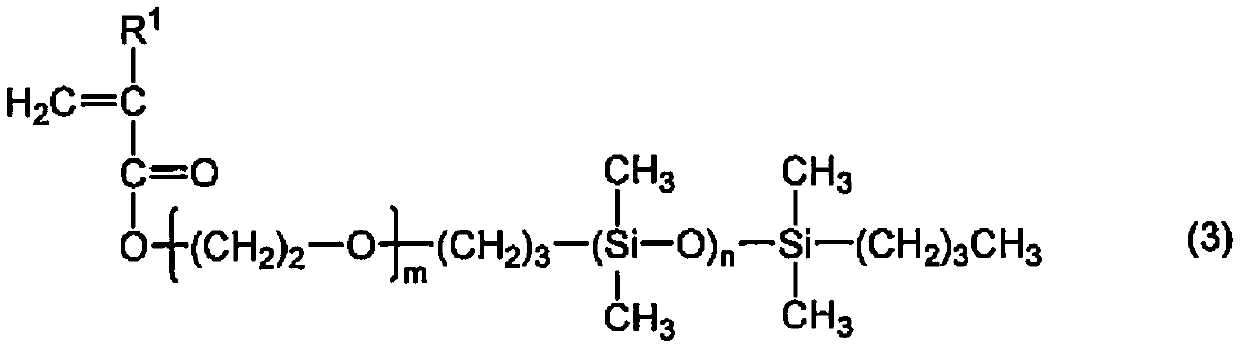

Monomer composition for contact lens, polymer for contact lens and production method thereof, and contact lens and production method thereof

A monomer composition, contact lens technology, applied in the directions of glasses/goggles, instruments, optics, etc., can solve the problem of decreased oxygen permeability, and achieve the effect of excellent surface hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of the composition of the present invention is not particularly limited. For example, it can be prepared by adding each component to a stirring (mixing) device in any order or together, and stirring (mixing) at a temperature of 10°C to 50°C until uniform. However, when the composition contains a polymerization initiator, it is necessary to pay attention not to initiate a polymerization reaction during mixing, and it is preferable to mix at 40° C. or lower. From the point of making the solubility of (A) component favorable, it is preferable to add and mix other components after mixing and dissolving three components of (A), (B) and (C)component.

[0085] The polymer of the present invention is formed from the polymer of the composition of the present invention described above. Hereinafter, the production method of the polymer of the present invention will be described. The production method shown below is only one embodiment of the method for obta...

Embodiment 1

[0176] 0.5g (5.0% by mass) of MPC, 1.0g (10.0% by mass) of HEA, 4.0g (40.0% by mass) of ES and 0.5g (5 parts by mass) of EtOH were mixed in a container and stirred at room temperature until MPC dissolves. Further, 1.9g (19.0 mass %) of FM-0711, 0.1 g (1.0 mass %) of TEGDV, 2.5 g (25.0 mass %) of NVP and 0.05 g (0.5 mass parts) of AIBN were added to the container. Stir until uniform to obtain a composition. The above-mentioned evaluation was performed on this composition.

[0177] 0.3 g of the above-mentioned composition was injected into a 25 mm × 70 mm × 0.2 mm spacer sandwiched between two polypropylene plates with a polyethylene terephthalate sheet having a thickness of 0.1 mm as a spacer. pool (cell), and placed in the oven. After replacing the inside of the oven with nitrogen, the temperature was raised to 65°C and maintained at this temperature for 3 hours, and then the temperature was further raised to 120°C and maintained for 2 hours to polymerize the composition to...

Embodiment 2~27

[0180] The compositions, polymers, and contact lenses of Examples 2 to 27 were prepared / manufactured in the same manner as in Example 1 except that the content ratio of each component and polymerization conditions were changed to those shown in Tables 1 to 4, and evaluation tests were performed. The results are shown in Tables 1-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com