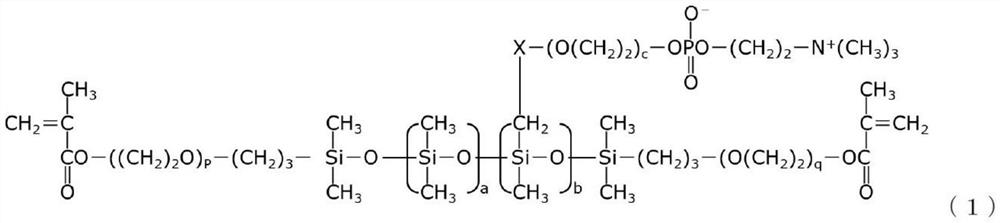

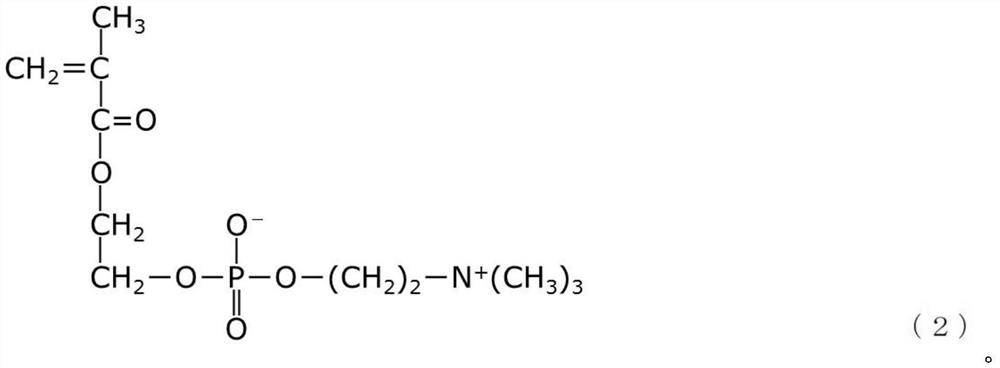

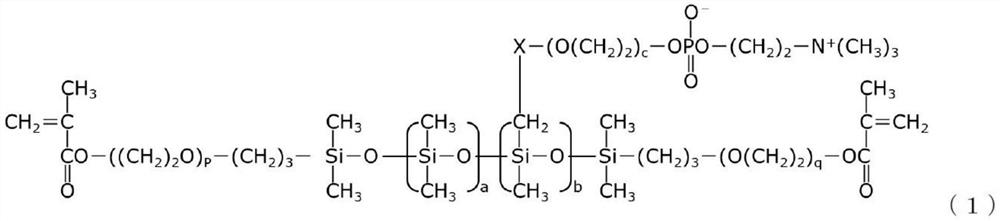

Monomer composition for contact lenses, polymer for contact lenses and method for producing same, and contact lens and method for producing same

A monomer composition, contact lens technology, applied in the direction of glasses/goggles, instruments, optical components, etc., can solve the problems that cannot be said to be obtained, sufficient performance, etc., and achieve the effect of excellent surface hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0139] The preparation method of the composition of the present invention is not particularly limited, for example, each component can be added in any order or added to a stirring (mixing) device, and stirred (mixed) at a temperature of 10°C to 50°C until uniform, thus prepared. However, when the composition contains a polymerization initiator, care must be taken not to initiate the polymerization reaction during mixing, and mixing is preferably performed at 40° C. or lower. In order to make the solubility of (A) component favorable, after mixing and dissolving three components of (A), (B), and (C)component, it is preferable to add and mix other components.

[0140] The polymer of the present invention consists of the polymer of the composition of the present invention described above. Hereinafter, the production method of the polymer of the present invention will be described. The production method shown below is only one embodiment of the method for obtaining the polymer, ...

Embodiment 1

[0221] Under the temperature condition of 25°C, after mixing and dissolving 11.8 mass % of A-1, 11.8 mass % of MPC and 31.5 mass % of ES, 7.9 mass parts of EGMV, 7.9 mass % of HBMA, 0.8 mass % of TEGDMA , 0.8% by mass of TEGDV, 11.8% by mass of MMA, 15.7% by mass of NVP, and 15.0 parts by mass of HeOH per 100% by mass of these in total were mixed and uniformly dissolved to obtain a composition. Table 2 shows the content ratio of each component.

[0222] Add 0.5 parts by mass of AIBN to the above composition, and pour it into a cell in which a polyethylene terephthalate sheet with a thickness of 0.1 mm is sandwiched between two polypropylene sheets as a spacer , and placed in the oven. After replacing the oven with nitrogen, raise the temperature to 100°C and maintain it for 2 hours at 0kgf / cm 2 The composition was polymerized (gauge pressure) to obtain the polymer of Example 1. Remove the polymer from the unit.

[0223] Reference (ISO 18369-3:2006, Ophthalmic Optics-Contac...

Embodiment 2~15 and comparative example 1 and 2

[0226] The compositions, polymers, and Contact lenses, and conduct evaluation tests. The results are shown in Table 2, Table 3 and Table 4.

[0227] [Table 2]

[0228]

[0229] *1 Blending amount of ingredients A~G; based on the total amount of monomer ingredients

[0230] * 2H component, initiator blending amount; relative to 100 parts by mass of monomer component

[0231] *3 contact lens

[0232] [table 3]

[0233]

[0234] *1 Blending amount of ingredients A~G; based on the total amount of monomer ingredients

[0235] * 2H component, initiator blending amount; relative to 100 parts by mass of monomer component

[0236] *3 contact lens

[0237] [Table 4]

[0238]

[0239] *1 Blending amount of ingredients A~G; based on the total amount of monomer ingredients

[0240] * 2H component, initiator blending amount; relative to 100 parts by mass of monomer component

[0241] *3 contact lens

[0242] According to the results of Table 2 and Table 3, in Examples 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com