An integrated wastewater treatment device and petrochemical secondary effluent treatment method

A wastewater treatment and secondary effluent technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of refractory organic matter and low removal efficiency of total nitrogen, and achieve large specific surface area and high speed , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

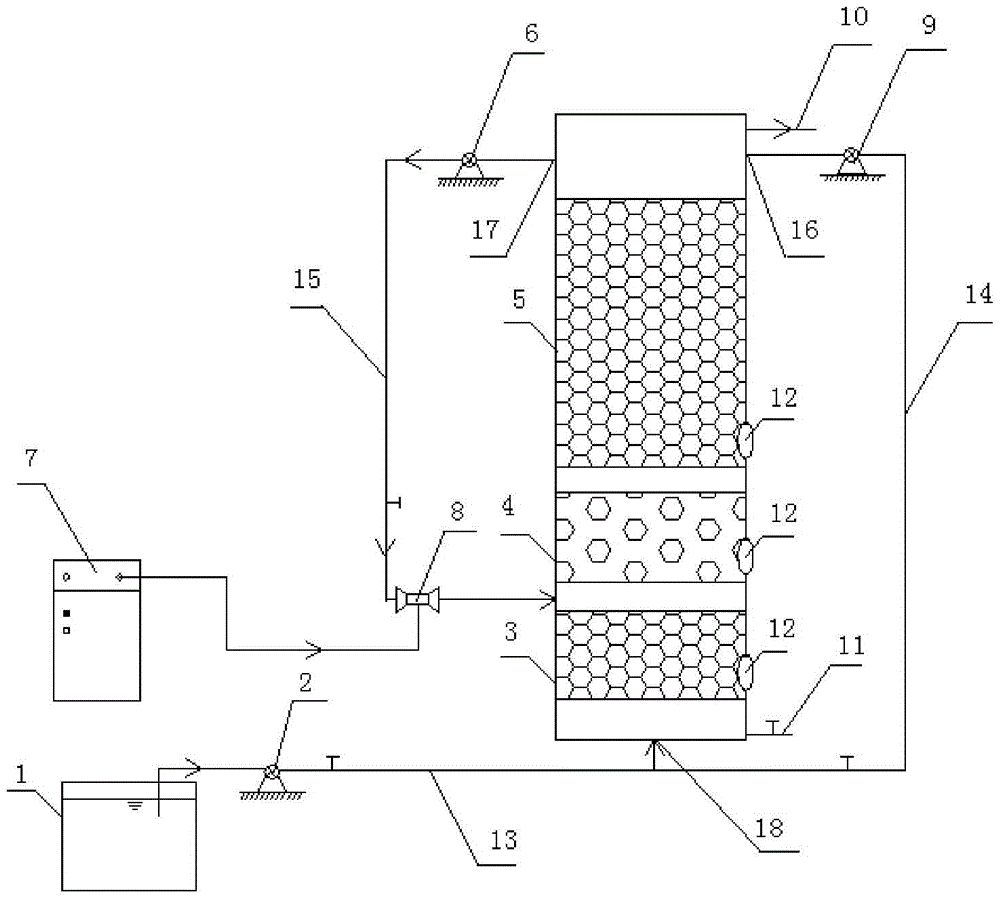

[0026] like figure 1 As shown, the integrated wastewater treatment device of the present invention includes a reactor, an ozone generator 7, a water tank 1, and a Venturi tube 8; wherein, the reactor includes a denitrification zone 3, an ozone catalytic oxidation zone 4, and an exposure Gas biofilter zone 5, a water inlet 18 is provided at the bottom of the denitrification zone 3, and a water outlet 10 is provided at the top; a first return port 16 and a second return port 17 are provided at the top of the reactor; The water inlet 18 is connected to the water tank 1 through the first pipeline 13, and connected to the first return port 16 through the second pipeline 14;

[0027] Described ozone generator 7 is connected with described Venturi tube 8, and the water inlet of described Venturi tube 8 is connected with described second return port 17 by the 3rd pipeline 15, and the water outlet of described Venturi tube 8 is connected with The lower part of the ozone catalytic oxid...

Embodiment 2

[0032] The method for carrying out petrochemical secondary effluent treatment using the integrated wastewater treatment device of the present invention comprises the following steps:

[0033] The wastewater in the water tank 1 enters the reactor through the water inlet pump 2, passes through the denitrification zone 3, the ozone catalytic oxidation zone 4 and the biological aerated filter zone 5 in turn, and flows out from the water outlet 10. At the same time, there are two return lines, One realizes reflux through the first reflux port 16, the first reflux pump 9 and the second pipeline 14, and the second one reaches the Venturi tube 8 through the second reflux port 17, the second reflux pump 6 and the third pipeline 15, and the reflux The waste water enters the lower part of the ozone catalytic oxidation zone 4 after being mixed with the ozone generated by the ozone generator 7 in the venturi tube 8 to realize reflux.

[0034] Preferably, the reflux of the ozone catalytic o...

Embodiment 3

[0036] In this example, the secondary effluent of a typical petrochemical wastewater is treated as the treatment object. The wastewater quality indicators are as follows: COD is between 60 and 120mg / L, BOD 5 Between 0.95~4mg / L, UV 254 Between 0.6~0.81 / cm, NH 4 + -N concentration is below 2mg / L, TN content is about 20mg / L, pH is between 7-8, SS is between 20-27mg / L, TP is between 1.0-1.5mg / L. The dosage of ozone is 10mg / L, the reflux ratio of the ozone catalytic oxidation unit is 200%, and the reflux ratio of the denitrification unit is 100%. After the above petrochemical wastewater is treated by this process, the effluent index COD is about 50mg / L, NH 4 + - The concentration of N is below 0.5mg / L, and the content of TN is about 15mg / L.

[0037] The fillers used in the denitrification zone and the BAF zone are all volcanic rocks, and the catalytic oxidation fillers used in the ozone catalytic oxidation unit are loaded Al 2 o 3 The catalyst packing, the residence time HRT ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com