Method for preparing polymer porous membrane without solvent

A porous membrane and polymer technology, which is applied in the field of solvent-free preparation of polymer porous membranes, can solve the problems of poor biotoxicity and biodegradability of organic solvents, difficulty in recovering organic solvents, and difficult treatment of membrane-making wastewater. The effect of solvent cost, reduced membrane cost, and excellent anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

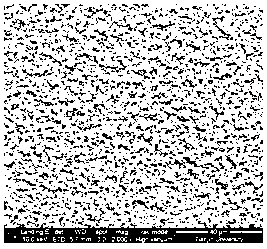

Embodiment 1

[0016] Weigh 2g of organic monomer hydroxyethyl methacrylate HEMA, 0.1g of initiator BPO, 0.5g of porogen TEOS, measure 80μL of cross-linking agent HDODA, mix and prepare a casting solution, and ultrasonically treat for 5min under nitrogen protection. Measure the casting solution with a volume of 20 μL and drop it on one end of the first glass piece (75mm*25mm), cover the casting solution on the first glass piece with one end of the second glass piece (75mm*25mm), and translate the second piece of glass The two glass sheets overlap the two glass sheets, and the casting solution is spread between the two glass sheets to form a liquid film. Transfer the two glass sheets sandwiched with the casting liquid film to a vacuum oven for heat treatment at 80°C under normal pressure for 24 hours, take it out and cool it to room temperature. Immerse the glass sheet with the solid film attached in 100mL of 1% hydrofluoric acid HF, the film is automatically peeled off from the glass sheet, ...

Embodiment 2

[0019] Weigh 2 g of organic monomer hydroxyethyl methacrylate HEMA, 0.1 g of initiator BPO, 2 g of porogen TEOS, and measure 80 μL of cross-linking agent HDODA, mix and prepare the casting solution, and ultrasonicate for 5 min under nitrogen protection. Measure the casting solution with a volume of 20 μL and drop it on one end of the first glass piece (75mm*25mm), cover the casting solution on the first glass piece with one end of the second glass piece (75mm*25mm), and translate the second piece of glass The two glass sheets overlap the two glass sheets, and the casting solution is spread between the two glass sheets to form a liquid film. Transfer the two glass sheets sandwiched with the casting liquid film to a vacuum oven for heat treatment at 80°C under normal pressure for 24 hours, take it out and cool it to room temperature. Immerse the glass sheet with the solid film attached in 100mL of 1% hydrofluoric acid HF, the film is automatically peeled off from the glass sheet...

Embodiment 3

[0022] Weigh 2g of organic monomer hydroxyethyl methacrylate HEMA, 0.1g of initiator BPO, 6g of porogen TEOS, measure 80μL of cross-linking agent HDODA, mix and prepare the casting solution, and ultrasonically treat for 5min under nitrogen protection. Measure the casting solution with a volume of 20 μL and drop it on one end of the first glass piece (75mm*25mm), cover the casting solution on the first glass piece with one end of the second glass piece (75mm*25mm), and translate the second glass piece The two glass sheets overlap the two glass sheets, and the casting solution is spread between the two glass sheets to form a liquid film. Transfer the two glass sheets sandwiched with the casting liquid film to a vacuum oven for heat treatment at 80°C under normal pressure for 24 hours, take it out and cool it to room temperature. The glass sheet with the solid film attached was immersed in 100mL of 1% hydrofluoric acid HF, the film was automatically peeled off from the glass shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com