Patents

Literature

35 results about "Ethylene glycol monovinyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

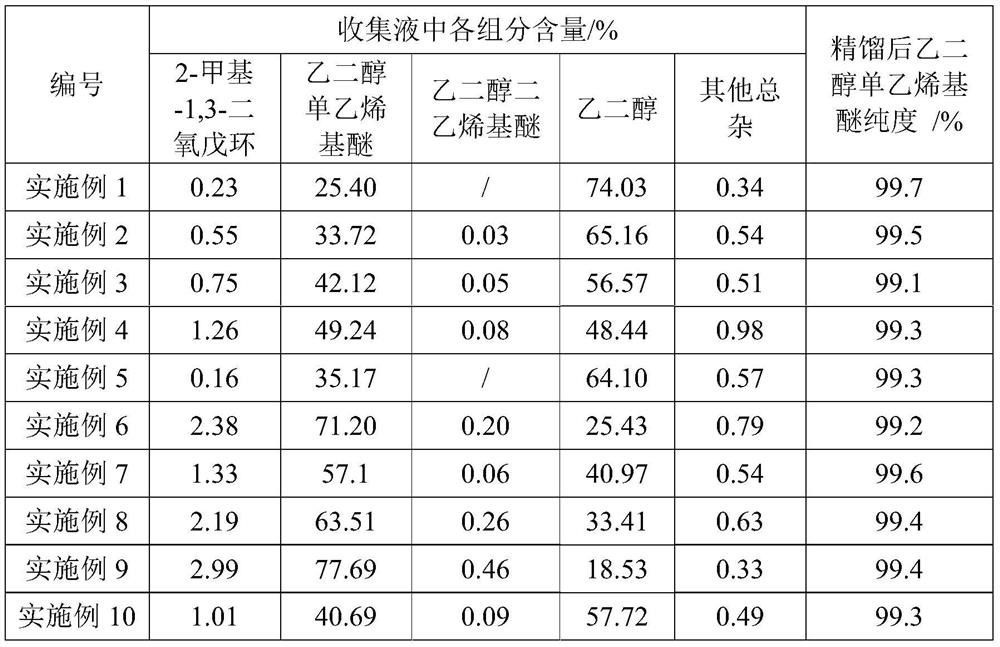

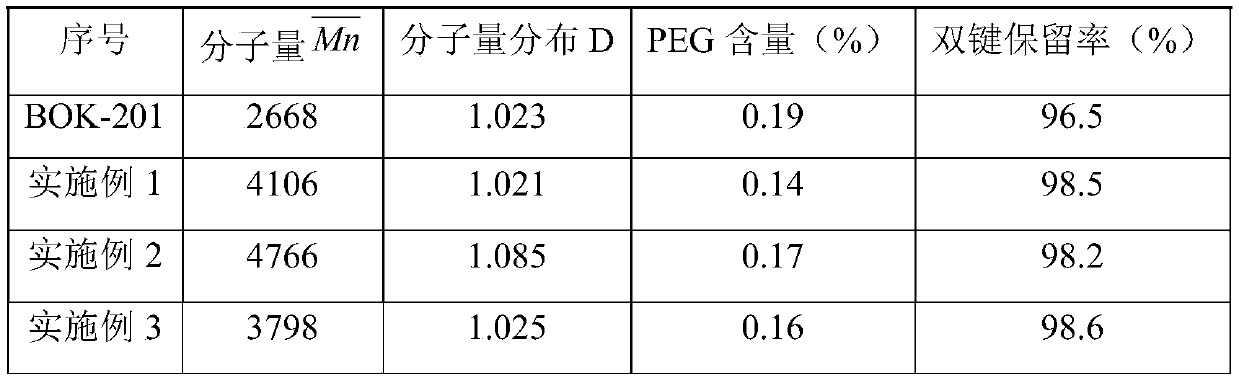

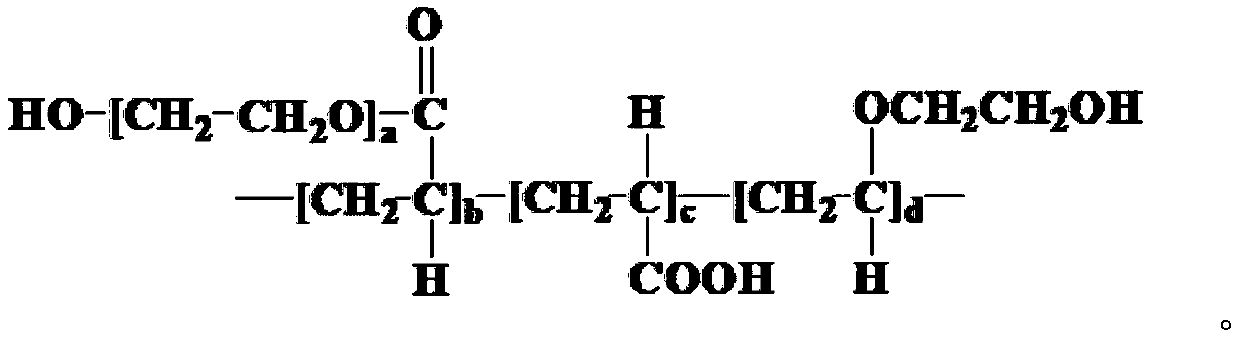

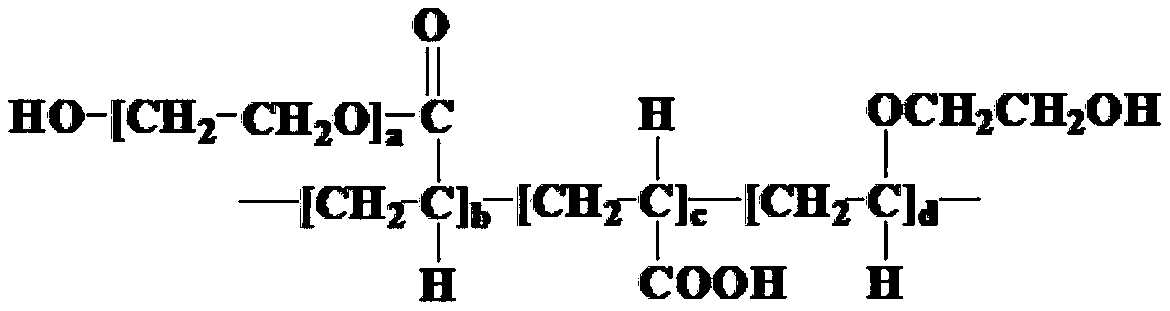

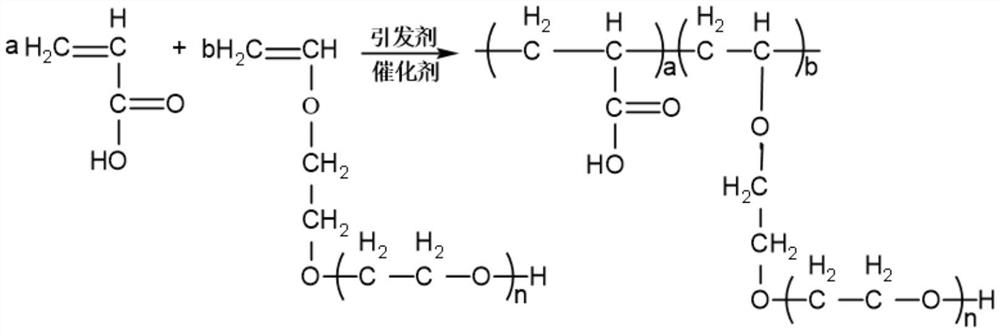

Polycarboxylate water reducer and preparation method thereof

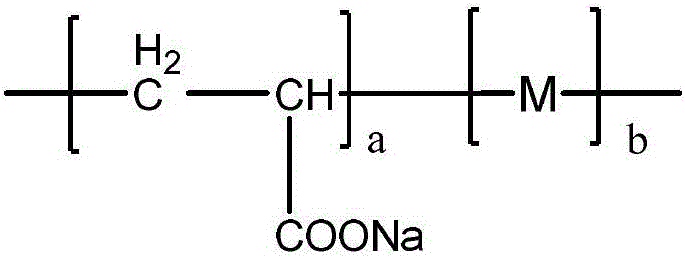

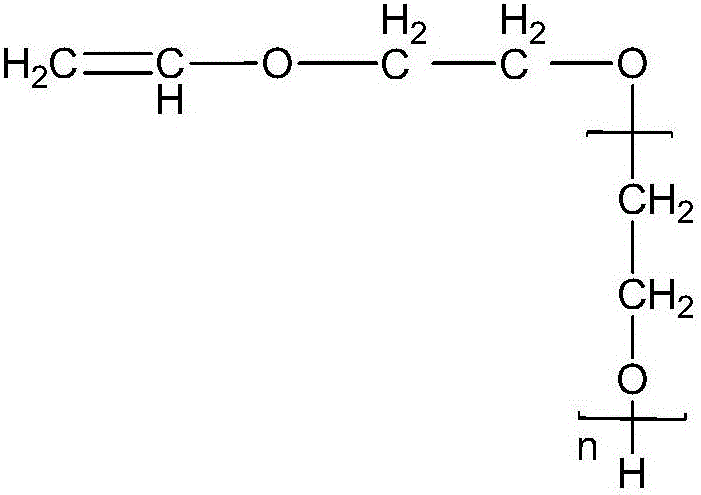

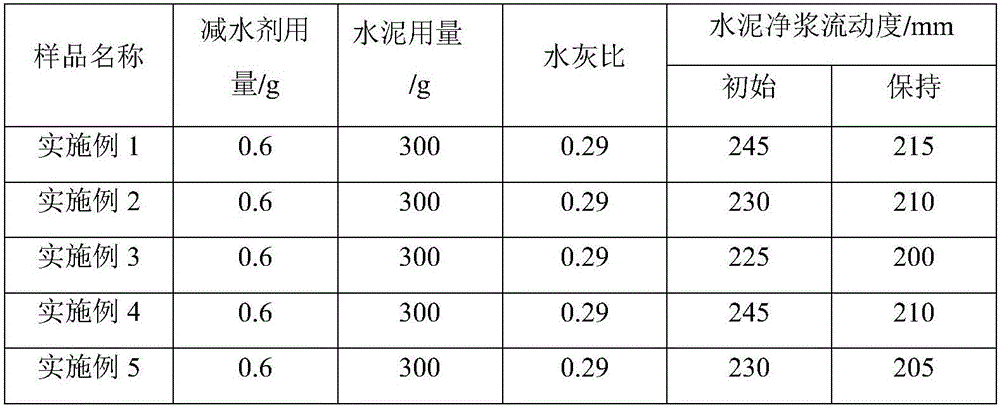

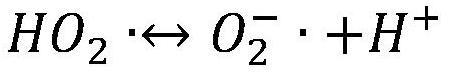

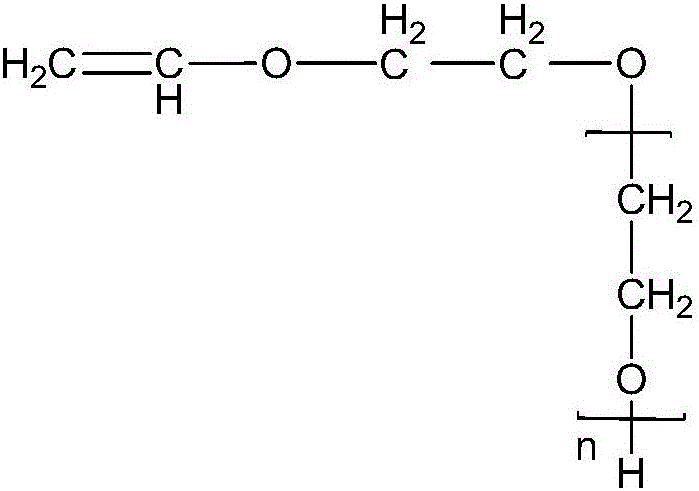

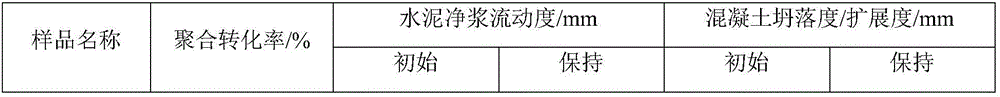

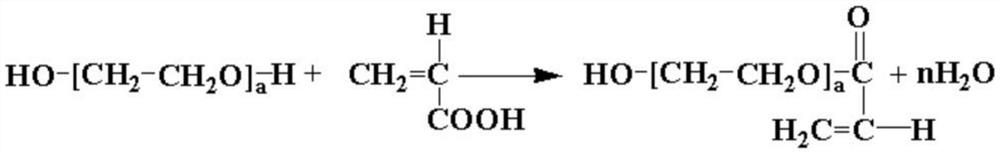

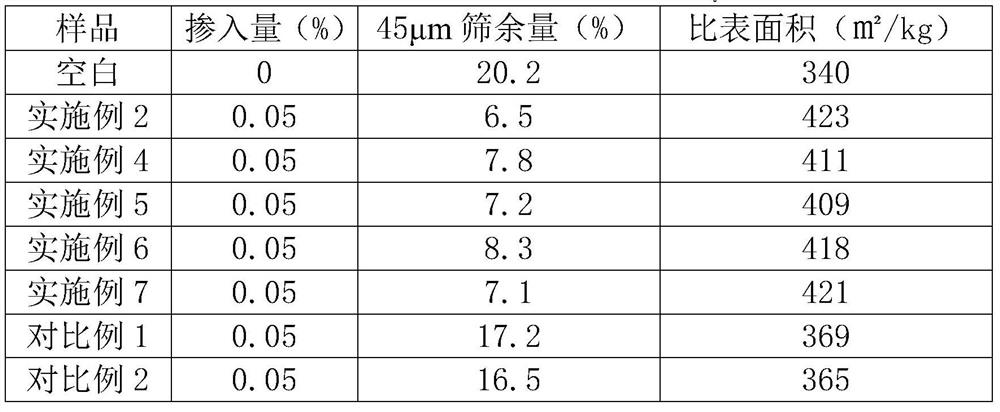

The invention provides a polycarboxylate water reducer and a preparation method thereof, and belongs to the field of preparation of concrete admixtures. The polycarboxylate water reducer is prepared by preparing an unsaturated polyether macromonomer by taking ethylene glycol monovinyl ether as an initiator first and then polymerizing the unsaturated polyether macromonomer (EPEG) with a small monomer acrylic acid. The polycarboxylate water reducer prepared by the preparation method provided by the invention has more hydrophilic groups in a molecular structure, high water reducing rate, obviously enhanced fluidity retention and obviously enhanced mud resistance, so that a relatively high construction requirement can be met.

Owner:SHANXI UNIV +1

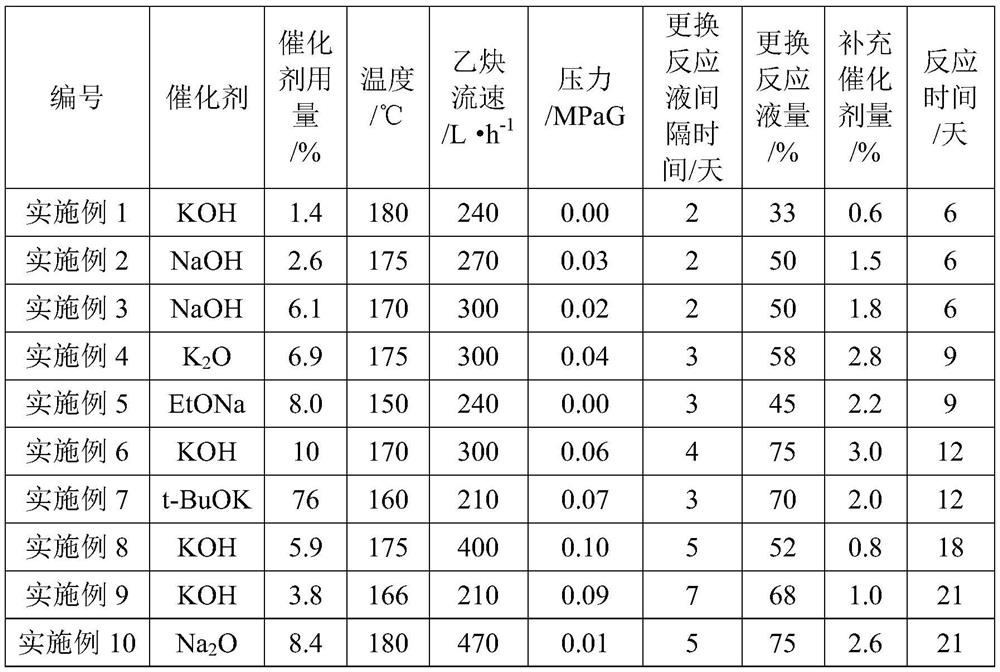

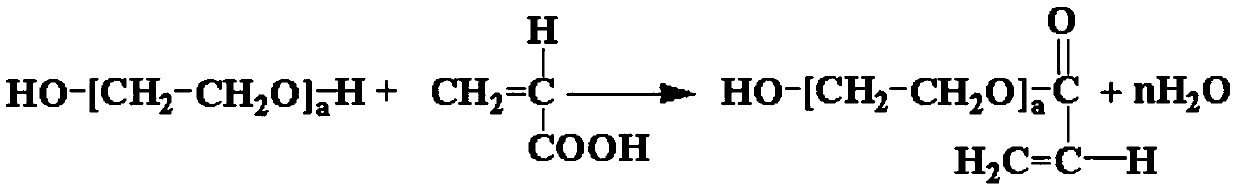

Preparation method of ethylene glycol monovinyl ether

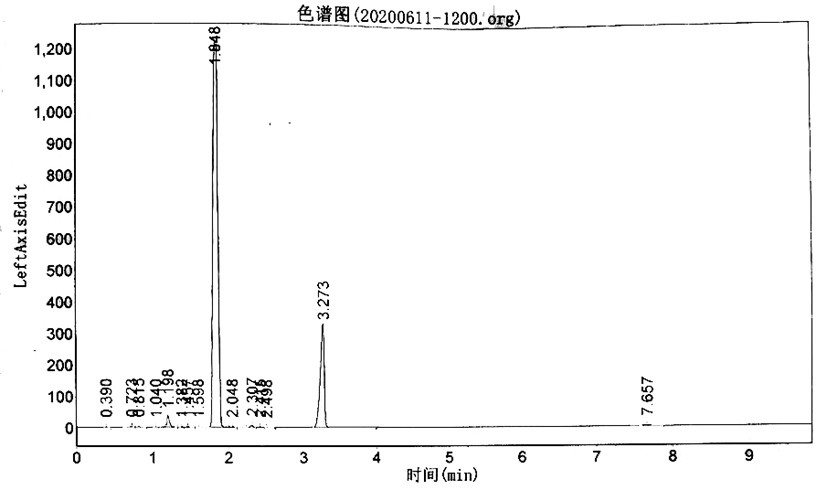

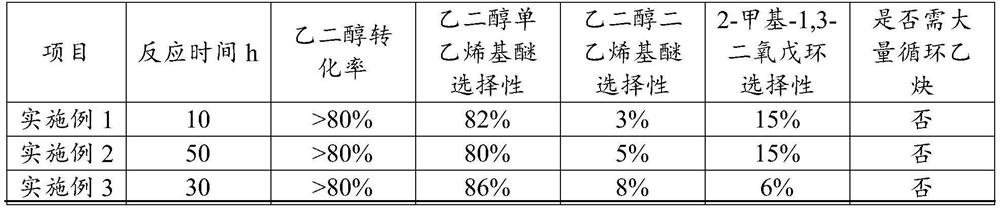

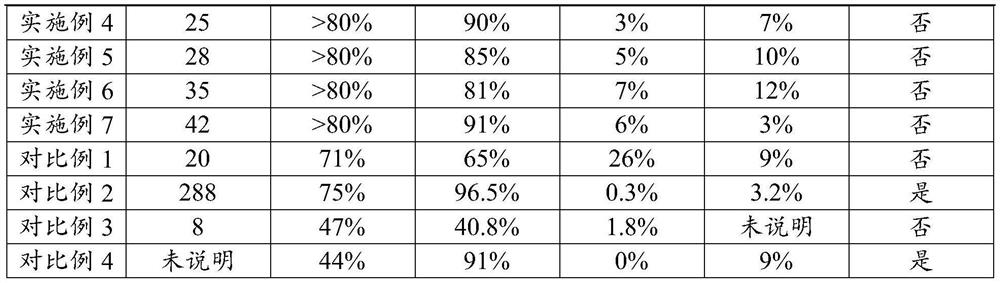

ActiveCN112299964AReduced risk of decomposition explosionLow reaction pressureEther preparation by compound additionVinyl etherPolymer science

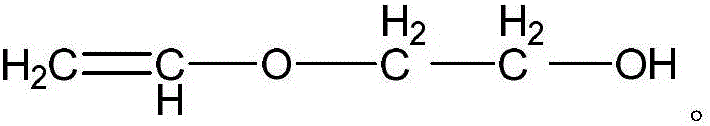

The invention belongs to the technical field of chemical engineering, and discloses a preparation method of ethylene glycol monovinyl ether, which comprises the following steps: 1) dissolving a basiccatalyst in ethylene glycol to form a reaction material, 2) adding the reaction material into a reactor, removing air in the reactor, continuously introducing acetylene for reaction, and continuouslysupplementing ethylene glycol in the reaction process to keep the liquid level of the reaction liquid in the reactor unchanged, 3) continuously taking the reaction product out of the reactor by acetylene, and distilling and condensing to form a collected liquid, and 4) rectifying the collected liquid to obtain ethylene glycol monovinyl ether. The preparation method provided by the invention has the advantages of high safety, few byproducts, simple raw materials and stable reaction, and can realize continuous production of ethylene glycol monovinyl ether.

Owner:BOAI NKY PHARMA LTD

Polycarboxylate superplasticizer based on 6C polyether macromonomer and preparation method thereof

The invention relates to the technical field of concrete admixtures, and discloses a polycarboxylate superplasticizer based on a 6C polyether macromonomer and a preparation method thereof, the polycarboxylate superplasticizer is prepared from the following raw material components through a chain transfer reaction: an acrylic monomer and diethylene glycol monovinyl ether, the molar mass ratio of the acrylic monomer to the diethylene glycol monovinyl ether is 3.5-5.5: 1; a catalyst used in the reaction is iron oxide, the iron oxide comprises ferric oxide and / or ferroferric oxide, and the addition amount of the iron oxide is 0.015-0.065% of the total amount of the raw material components; and the invention also discloses a preparation method. According to the polycarboxylate superplasticizer, the production condition is simple and easy to implement, industrial production is easy to realize, the cement dispersing performance and slump retaining performance of the product are excellent, the compressive strength of hardened concrete doped with the product in all ages is good, and the polycarboxylate superplasticizer is suitable for mortar and concrete preparation.

Owner:四川鸿鹏新材料有限公司 +1

Process of synthesizing comprehensive water reducer by using hexa-carbon monomer

The invention discloses a process of synthesizing comprehensive water reducer by using a hexa-carbon monomer. The process comprises the following specific steps: preparing 4560 kg of bottom water in areaction kettle, pumping 3060 kg of the hexa-carbon monomer, and uniformly stirring the mixture; in summer production, starting heat exchanger cooling water to cool a bed charge, and controlling thetemperature of the bed charge at 8-12 DEG C; in winter production, introducing steam, and controlling the temperature of the bed charge at 24-26 DEG C, wherein the temperatures in the reaction processare controlled as follows: the temperature of the whole reaction system is controlled at 10-20 DEG C in summer and the temperature of the whole reaction system is controlled at 25-30 DEG C in winter.By carrying out low-temperature production with a diethylene glycol monovinyl ether, the obtained product is wide in adaptability, can be suitable for various gel materials, has water reducing and slump preventing functions, and can improve the construction performance of concrete. The compounding cost of the water reducer can be saved, the process is simple and convenient to operate, no wastes are available in the production process, and the process is environment-friendly and reliable, and industrial production on a large scale is facilitated.

Owner:湖南加美乐素新材料股份有限公司

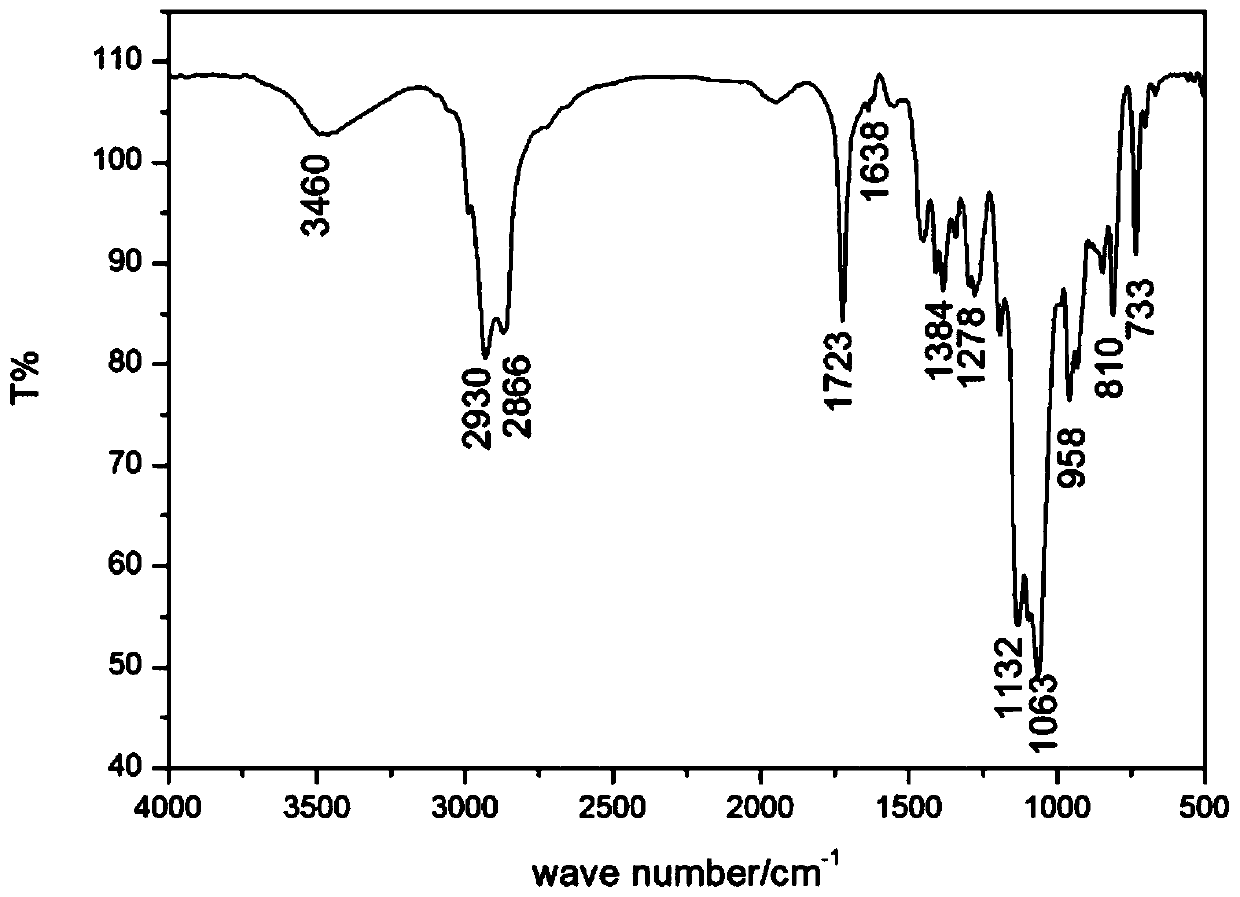

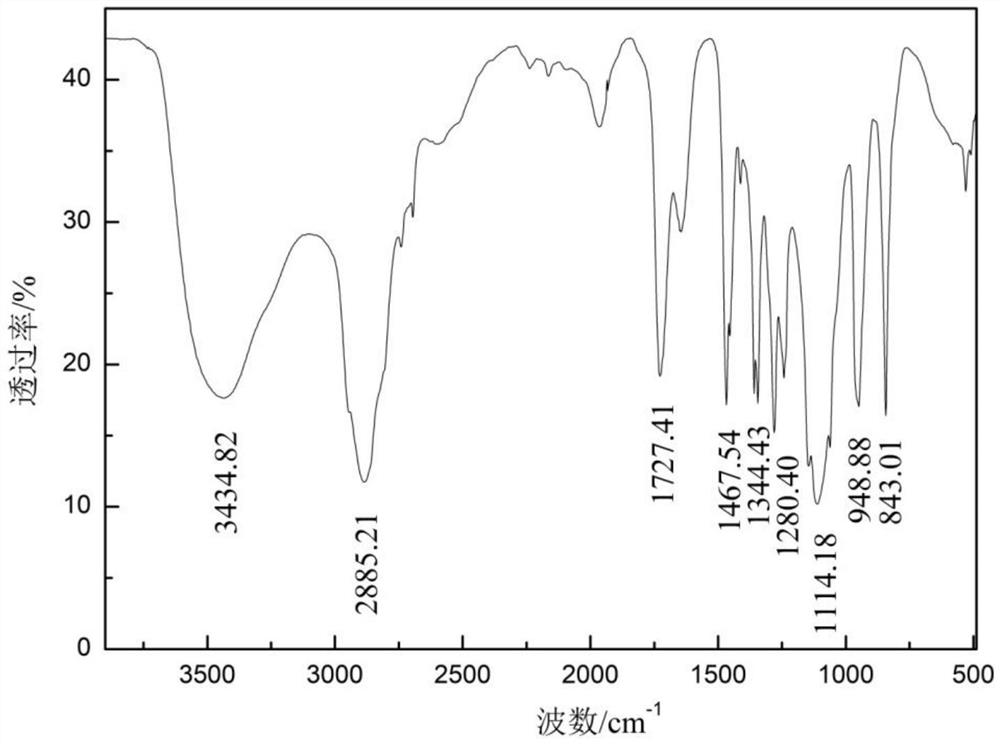

Macromer for preparing polycarboxylic acid water-reducer and preparation method thereof

The invention provides a macromer for preparing polycarboxylic acid water-reducer and a preparation method thereof. The macromer is synthesized by the reaction of 2-(vinyloxy)ethanol and epoxyethane as main materials. The macromer has simple molecular structure, the production process is safe and steady, and the cost is low; the reactivity is high and the conditions is easily controlled when the macromer is used for preparing polycarboxylic acid water-reducer, the obtained polycarboxylic acid water-reducer has high performance and performance and price ratio.

Owner:SHANXI UNIV +1

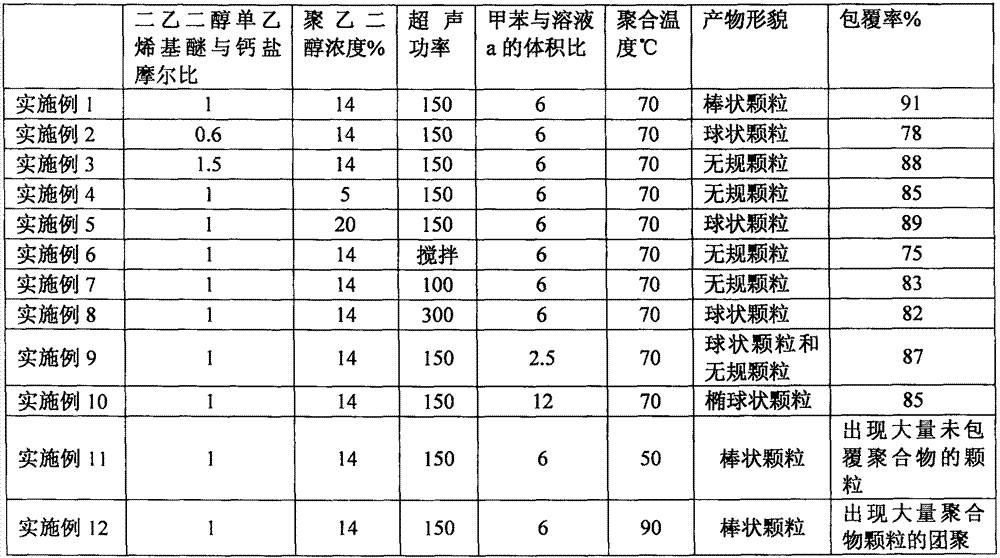

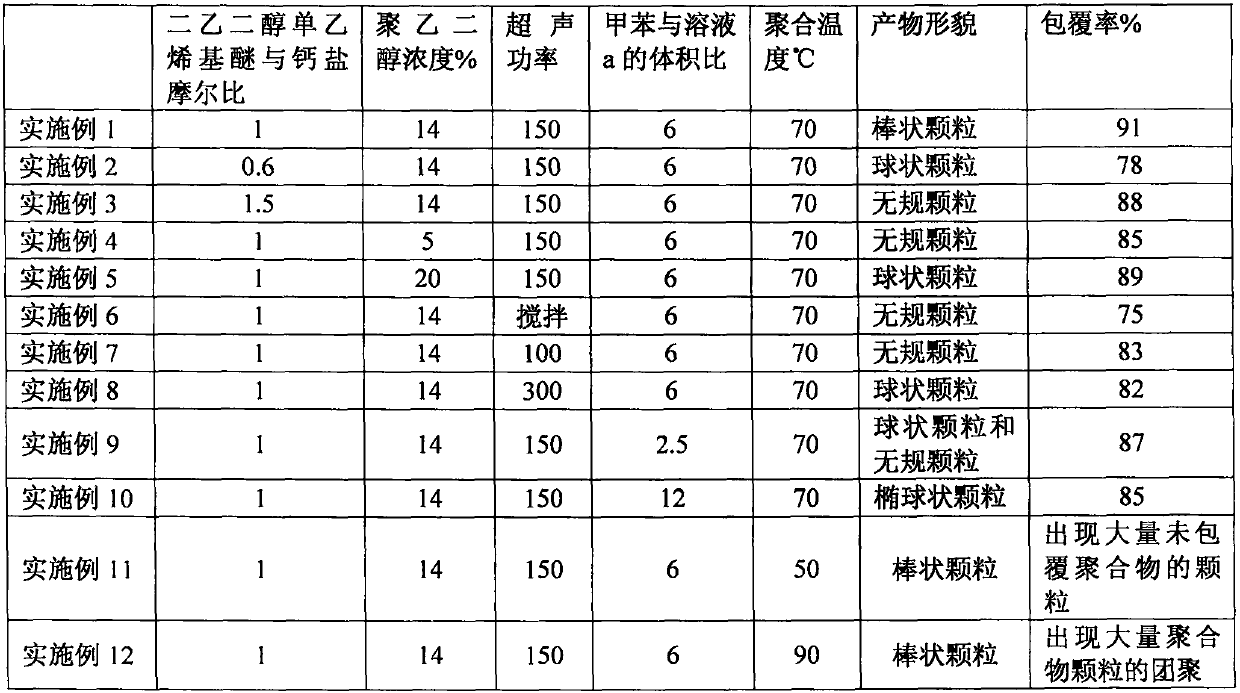

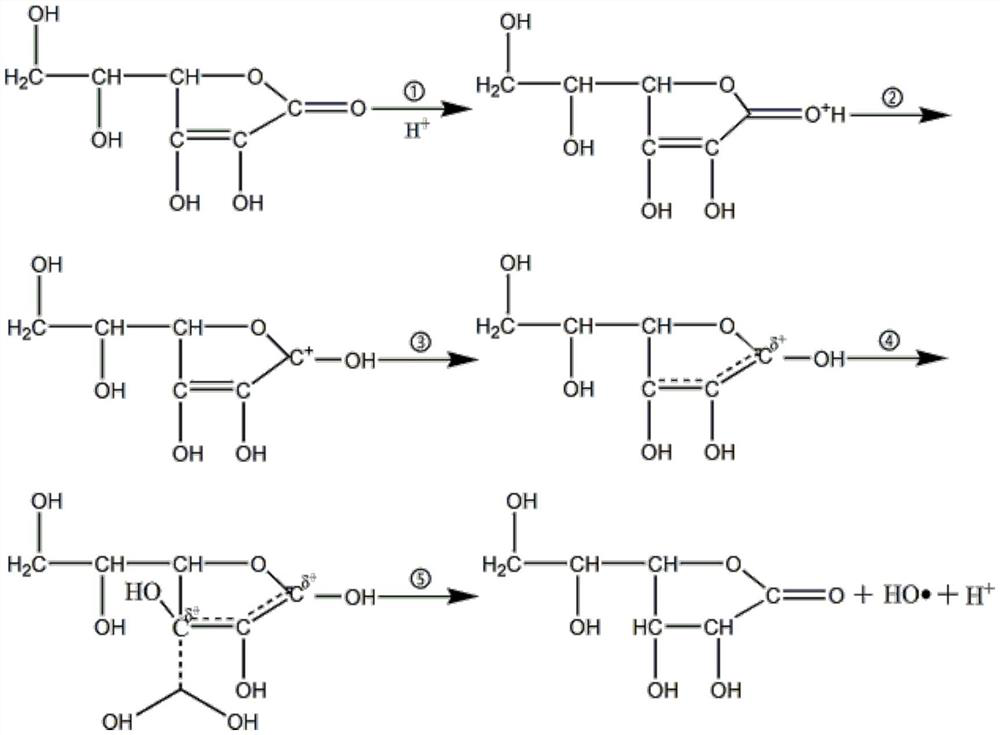

Preparation method of calcium carbonate/polymer core-shell structure

The invention relates to a preparation method of a calcium carbonate / polymer core-shell structure. According to the preparation method, diethylene glycol monovinyl ether is used as a crystal form controlling agent, a shape controlling agent and a polymeric monomer and interface reaction of enabling ultrasonic initiation reactants to collide between organic-phase and water-phase liquid drops is carried out to initiate the monomer to polymerize, so that stable vaterite-phase calcium carbonate / polymer nanoparticles with a (100) face are obtained and the particle size is about 200nm to 300nm.

Owner:宁波普莱斯帝金属制品有限公司

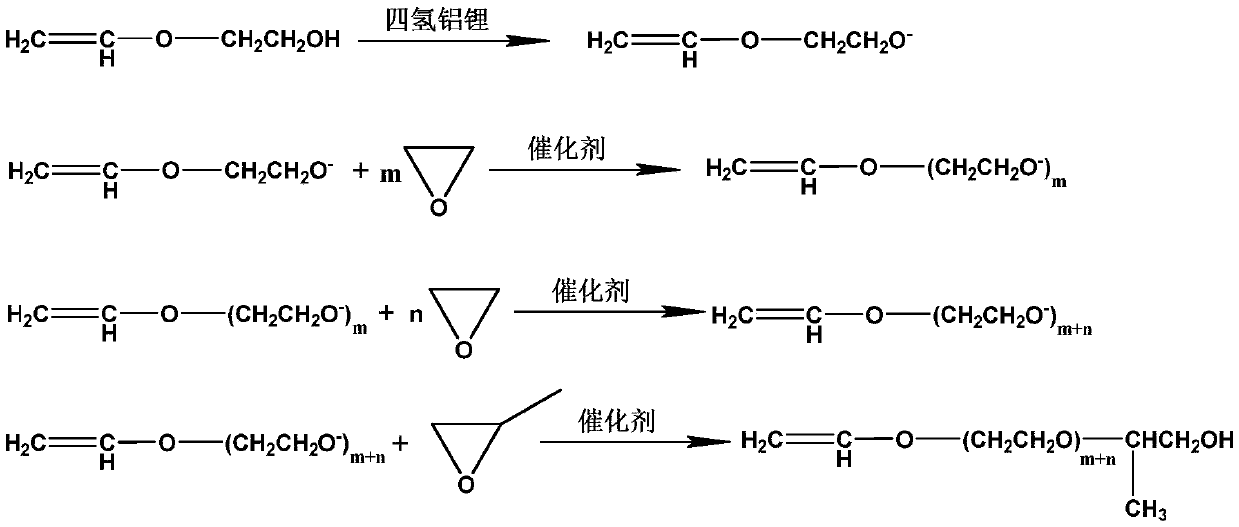

Preparation method of polycarboxylic acid water reducer macromonomer ethylene glycol monovinyl polyoxyethylene ether

The invention relates to a polycarboxylic acid water reducer, and concretely relates to a preparation method of a polycarboxylic acid water reducer macromonomer ethylene glycol monovinyl polyoxyethylene ether. The method comprises the following steps: reacting ethylene glycol monovinyl ether with lithium aluminum hydride to obtain a catalyst, carrying out a condensation reaction on the ethylene glycol monovinyl ether and ethylene oxide under the action of the catalyst to obtain an ethylene glycol monovinyl ether oligomer, carrying out a condensation reaction on the ethylene glycol monovinyl ether oligomer and ethylene oxide under the action of an alkaline catalyst, performing termination with epoxypropane, and adding glacial acetic acid to neutralize in order to obtain the ethylene glycolmonovinyl polyoxyethylene ether. The ethylene glycol monovinyl polyoxyethylene ether obtained in the invention has the advantages of narrow relative molecular weight distribution, high double-bond reservation rate, simple process, safety, low reaction temperature, short reaction time and low production cost.

Owner:山东卓星化工有限公司

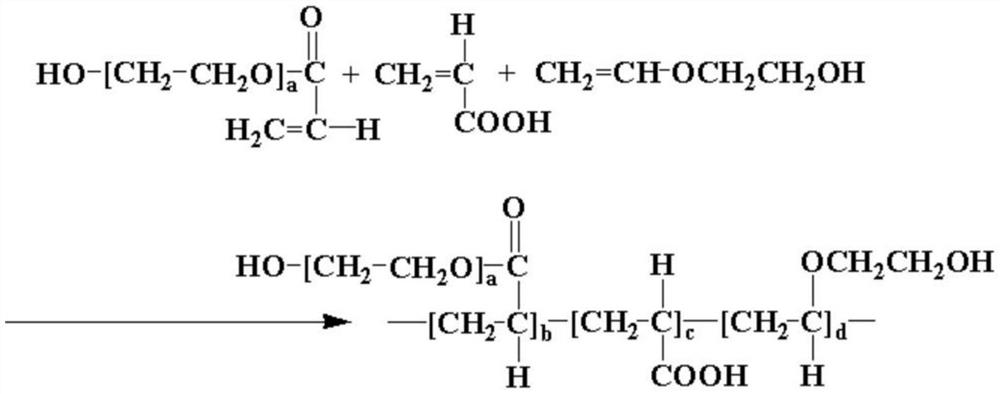

Highly-adaptable polycarboxylic acid water reducer and synthesis method thereof

The invention discloses a highly-adaptable polycarboxylic acid water reducer and a synthesis method thereof. The method comprises the following steps: sequentially adding polyethylene glycol, a polymerization inhibitor and acrylic acid into a reaction container, carrying out thorough stirring, adding a catalyst into a container, and carrying out a reaction under a heating condition to form a polyester functional monomer; and carrying out a polymerization reaction on ethylene glycol monovinyl ether, acrylic acid, a composite initiator and the obtained polyester functional monomer in water usedas a solvent at normal temperature under normal pressure to obtain the polycarboxylic acid water reducer. The water reducer has the advantages of simple structure, excellent performances, strong adaptability, and suitableness for industrial promotion.

Owner:吉林省天宝建筑材料有限公司

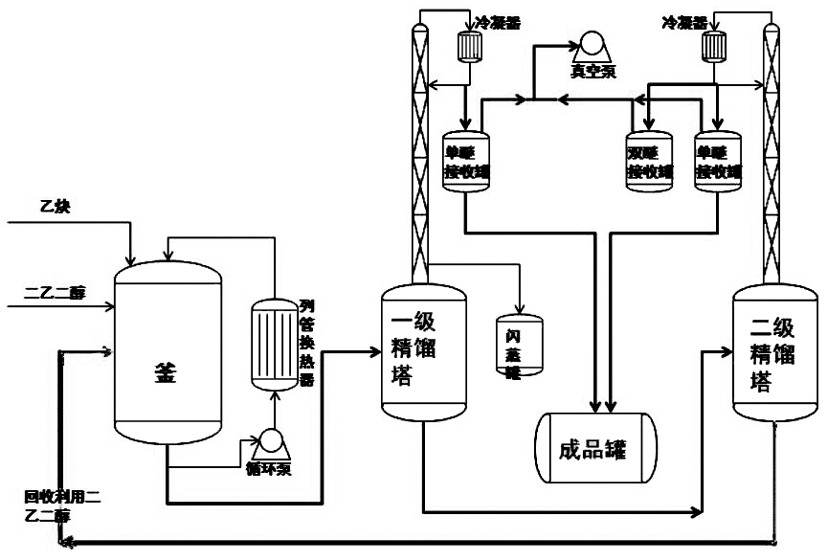

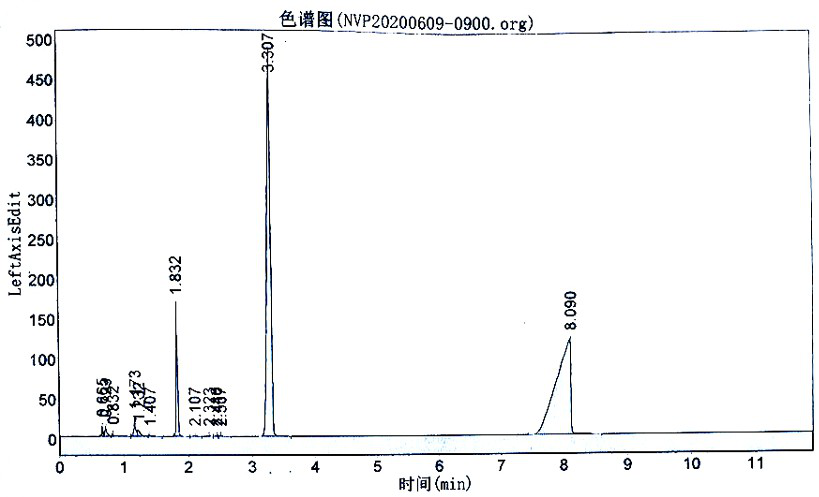

Alcohol head polymerization purification preparation method

PendingCN113956137AEasy to separateEther separation/purificationEther preparation by compound additionVinyl etherPolymer science

The invention provides an alcohol head polymerization purification preparation method used for preparing C6 alcohol head diethylene glycol monovinyl ether. The preparation method comprises the following steps: performing sufficient polymerization reaction on diethylene glycol, a pre-prepared mixed solution and acetylene in a reaction kettle to obtain a reaction mixture, rectifying the reaction mixture through a primary rectifying tower and a secondary rectifying tower, and collecting a diether byproduct and C6 alcohol head diethylene glycol monovinyl ether by adjusting the reflux ratio. The purity of the obtained C6 alcohol head is 98% or above, and the C6 alcohol head is basically free of diether byproducts and reaches the delivery standard.

Owner:衢州建华南杭药业有限公司

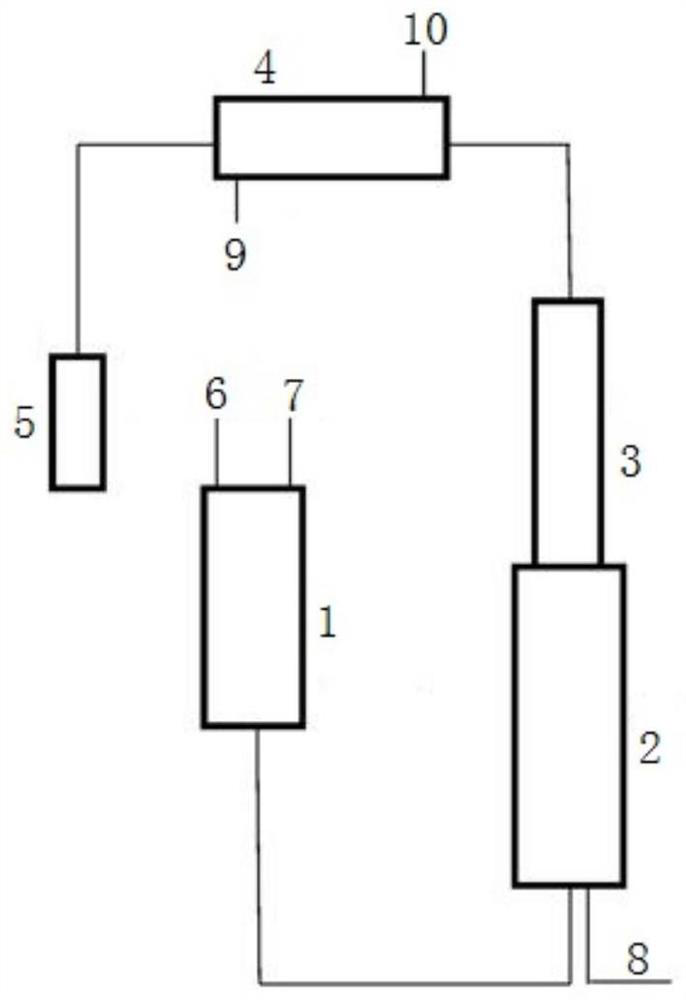

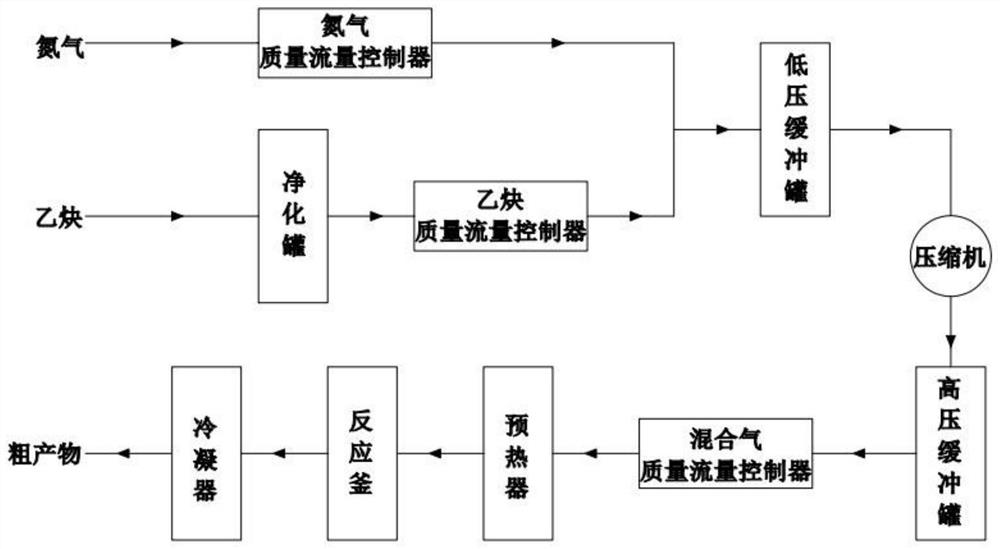

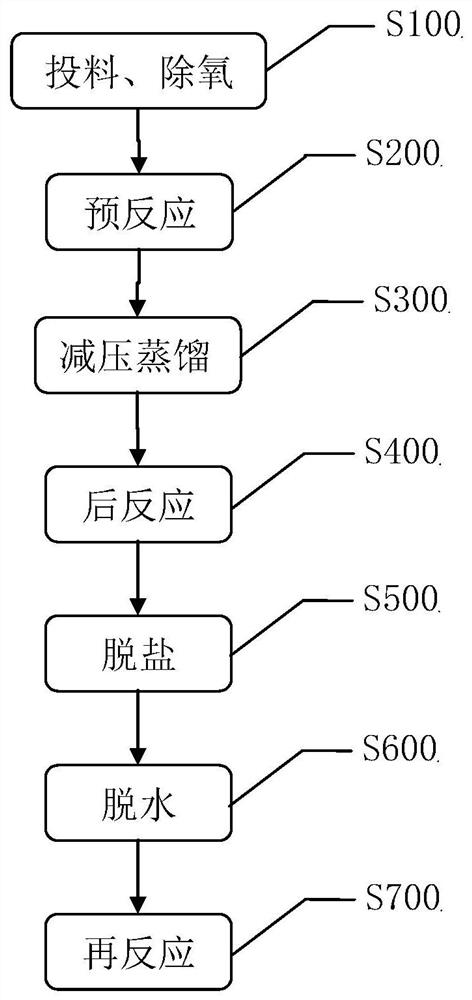

Preparation method and production system of ethylene glycol monovinyl ether

PendingCN114230445AAvoid Decomposition HazardsHigh selectivityEther preparation by compound additionVinyl etherPtru catalyst

The invention discloses a preparation method and a production system of ethylene glycol monovinyl ether, and belongs to the technical field of organic synthesis. The preparation method comprises the following steps: taking acetylene and ethylene glycol as raw materials, intermittently introducing acetylene into ethylene glycol containing a catalyst, carrying out pressurized reaction in a high-pressure closed reaction kettle, and adding inert gas as shielding gas of acetylene; by intermittently carrying out gas stripping, condensation and recovery of the product in the reaction process, generation of side reactions can be effectively avoided, so that the product selectivity is improved. The preparation method disclosed by the invention is simple to operate, high in conversion rate, few in byproducts and relatively high in reaction selectivity and safety.

Owner:ZHEJIANG HUANGMA TECH +3

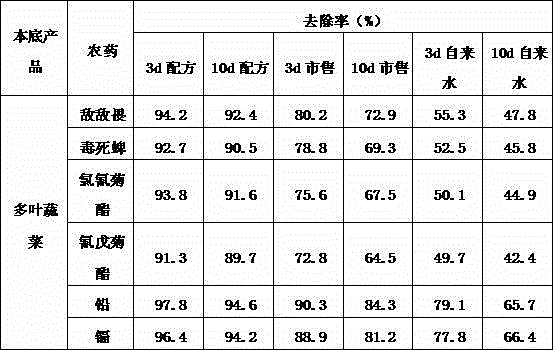

Leafy vegetable washing agent

InactiveCN104531405AEasy to cleanSurface-active non-soap compounds and soap mixture detergentsCyclohexene2-Ethylhexanoic acid

The invention relates to washing agents, in particular to a leafy vegetable washing agent. The leafy vegetable washing agent is formed by peroxide tertiary amyl-2-ethylhexoate, 4-methyl-1-(1-ethyl methyl)-3-cyclohexene-1-alcohol, diethylene glycol monovinyl ether, ethyl 3-ethoxypropionate, 2-(acetamido)-4-amino-4-ketobutyric acid, alpha-sulpho-omega-hydroxyl poly ethylene oxide-C10-16-alkyl ether, diethylene glycol dimethyl acrylic ester, 2,7-double [2-(diethyl amino) ethyoxyl]-9-fluorenone hydrochloride and polyquaternium-37. According to the leafy vegetable washing agent, cleaning is conduced according to the shape characteristics that holes and seams of leafy vegetables are numerous and leaves are overlapped, the surfaces of the vegetables are cleaned in an all-dimensional mode, and the cleaning effect is good. Meanwhile, the washing agent is mild in composition property, no stimulation can be generated to the skin of a human body, and people can clean the vegetables at ease.

Owner:烟台顺隆化工科技有限公司

High-temperature-resistant UV visbreaking adhesive tape

InactiveCN110484150AImprove initial tack performanceNo pollution in the processFilm/foil adhesive primer layersFilm/foil adhesive release linersTemperature resistancePollution

The invention belongs to the technical field of visbreaking adhesive tapes. The invention relates to a high-temperature-resistant UV visbreaking adhesive tape. The UV visbreaking adhesive tape comprises a release film layer, a UV visbreaking adhesive layer, a bottom coating, a flexible base material layer and a UV active coating which are sequentially arranged from bottom to top, and is characterized in that: the UV visbreaking adhesive is prepared from the following raw materials in parts by weight: 20-30 parts of cured resin, 25-35 parts of methacrylic acid and 5-9 parts of 2-hydroxyl-2-methyl-1-phenyl-1-acetone, 45-50 parts of diethylene glycol monovinyl ether, 0.5-1 part of azodiisoheptonitrile and 4-8 parts of a trimethylolpropane tri-crosslinking agent; after UV illumination, the stripping force can be reduced from original 1600 gf / 25mm to 20 gf / 25mm or below; the prepared adhesive tape has the advantages of no pollution, no residue, difficult precipitation, realization of high temperature resistance at 150 DEG C for 1h, substantial improvement of the initial adhesion of the glue, and suitableness for a plurality of coating modes; and the product obtained after coating of a prepared pressure-sensitive adhesive on a PET substrate and UV curing has excellent permanent adhesion, and has small high temperature increase.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

A kind of preparation method of calcium carbonate/polymer core-shell structure

The invention relates to a preparation method of a calcium carbonate / polymer core-shell structure. According to the preparation method, diethylene glycol monovinyl ether is used as a crystal form controlling agent, a shape controlling agent and a polymeric monomer and interface reaction of enabling ultrasonic initiation reactants to collide between organic-phase and water-phase liquid drops is carried out to initiate the monomer to polymerize, so that stable vaterite-phase calcium carbonate / polymer nanoparticles with a (100) face are obtained and the particle size is about 200nm to 300nm.

Owner:宁波普莱斯帝金属制品有限公司

Waterproof coating for building external wall

The invention discloses a waterproof coating for a building external wall. The waterproof coating is characterized by being prepared from the following raw materials in parts by weight: 40 to 80 parts of acrylate emulsion, 25 to 30 parts of ethylene-vinyl acetate copolymer emulsion, 3 to 6 parts of modified hydroxypropyl methyl cellulose, 0.5 to 2.2 parts of polydimethylsiloxane, 2 to 10 parts of cotton flock, 10 to 25 parts of precipitated calcium carbonate, 5 to 15 parts of asbestos powder, 4 to 6 parts of ethylene glycol monovinyl ether, 3 to 5 parts of 2-hydroxypropyl cellulose, 1 to 2 parts of a fungicide, 1 to 2 parts of an anti-precipitant, 1 to 2 parts of ammonia water and 50 to 100 parts of water. The waterproof coating for the building external wall, disclosed by the invention, is good in waterproof performance, excellent in mechanical property and long in service life.

Owner:安徽圣德建材科技有限公司

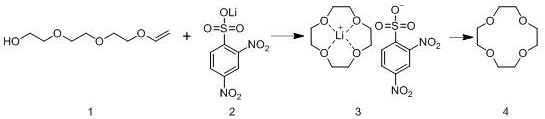

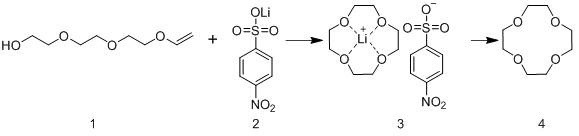

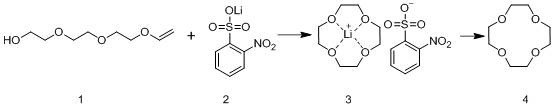

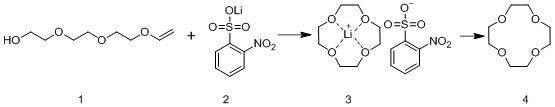

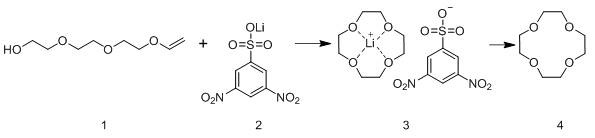

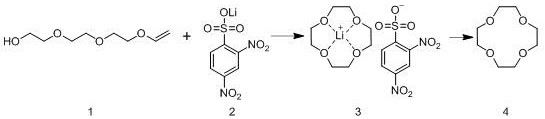

12-crown ether-4 lithium salt complex as well as preparation method and application thereof

ActiveCN113248468AReasonable designRaw materials are safe and easy to obtainSulfonic acids salts preparationVinyl etherBiochemical engineering

The invention discloses a 12-crown ether-4 lithium salt complex and a preparation method thereof, and a method for preparing 12-crown ether-4 by adopting the complex. The preparation method of the 12-crown ether-4 comprises the following steps: by taking a compound triethylene glycol monovinyl ether in a formula 1 as a raw material, adding an alkaline substance into a first reaction solvent for catalytic reaction with a compound lithium alkoxide containing a substituent group in a formula 2 under the condition of air isolation, and obtaining a compound 12-crown ether-4 lithium salt complex in a formula 3 after the reaction is completed; and then adding a compound 12-crown ether-4 lithium salt complex as shown in a formula 3 and an acidic material into a second reaction solvent, reacting at the reaction temperature of-20 to 100 DEG C, and after the reaction is completed, obtaining a compound 12-crown ether-4 as shown in a formula 4. The design route is reasonable in design, the raw materials are safe and easy to obtain, the process safety is high, the reaction selectivity is high, the product purity is high, the method is friendly to operators, the production cost is greatly reduced, and the requirements of industrial production of products can be fully met.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

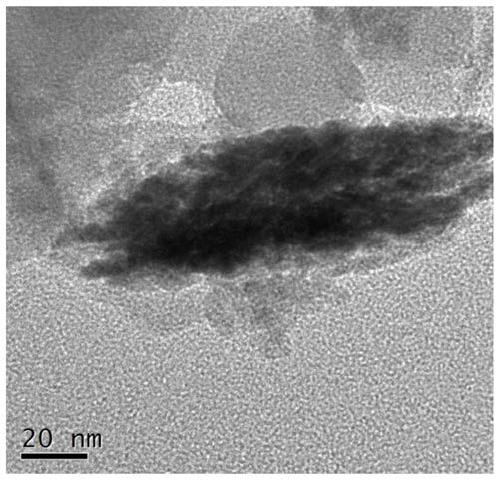

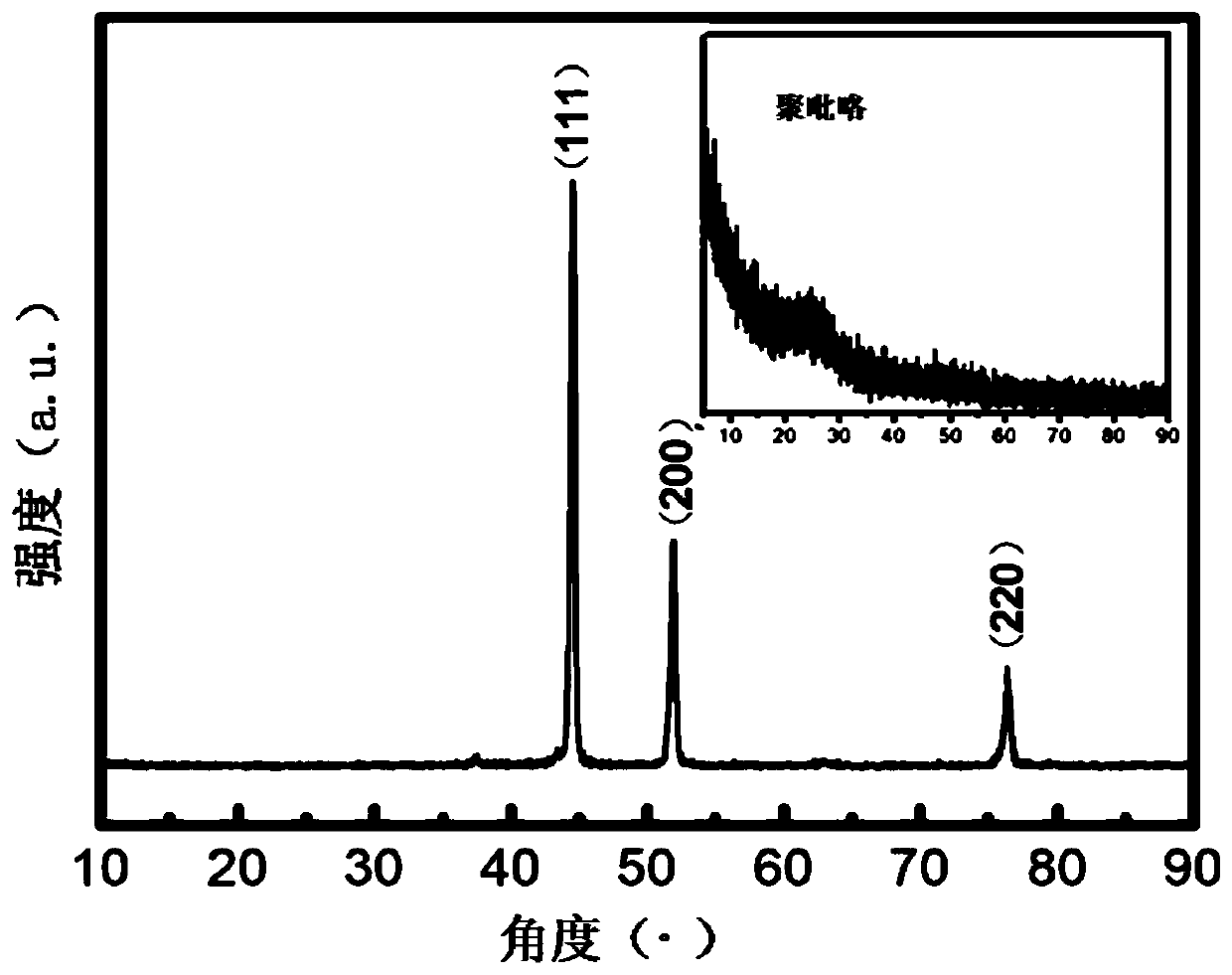

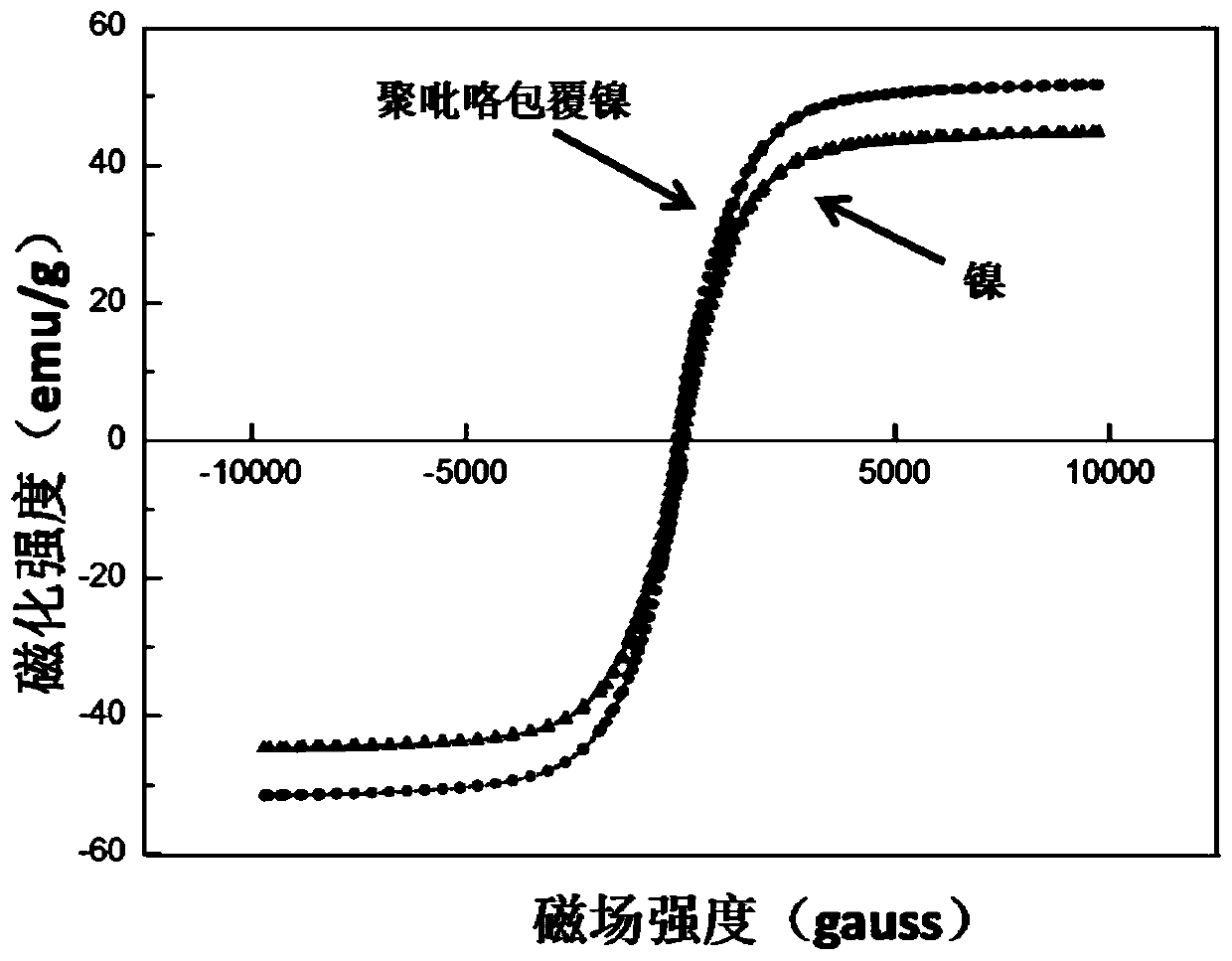

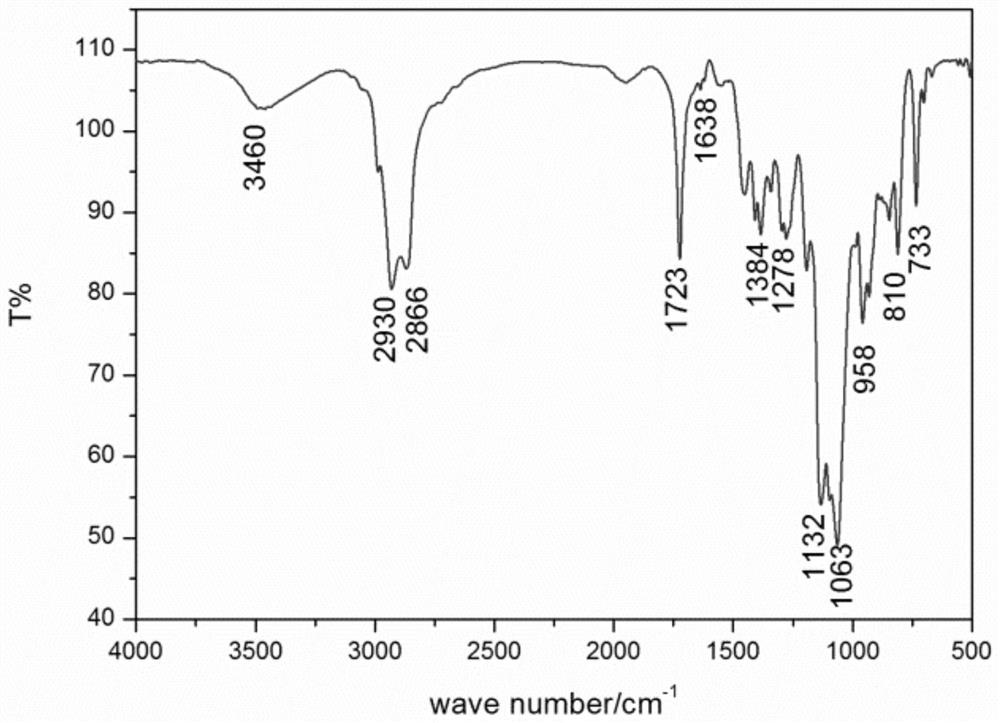

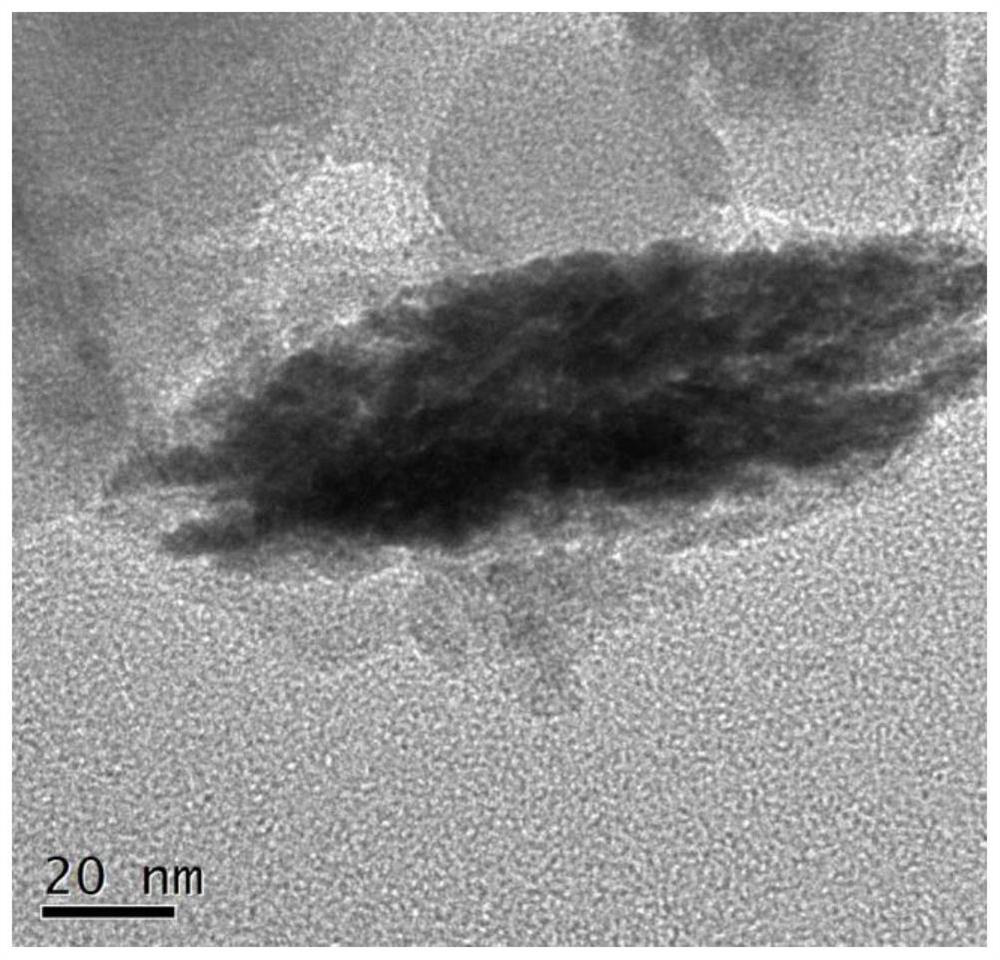

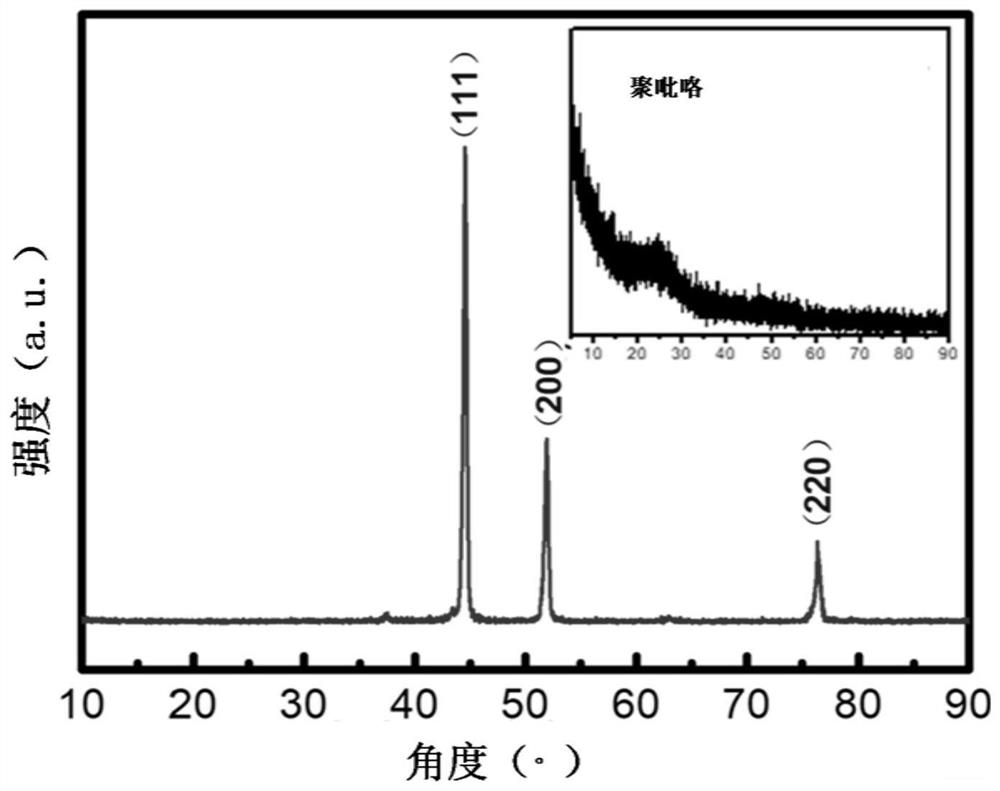

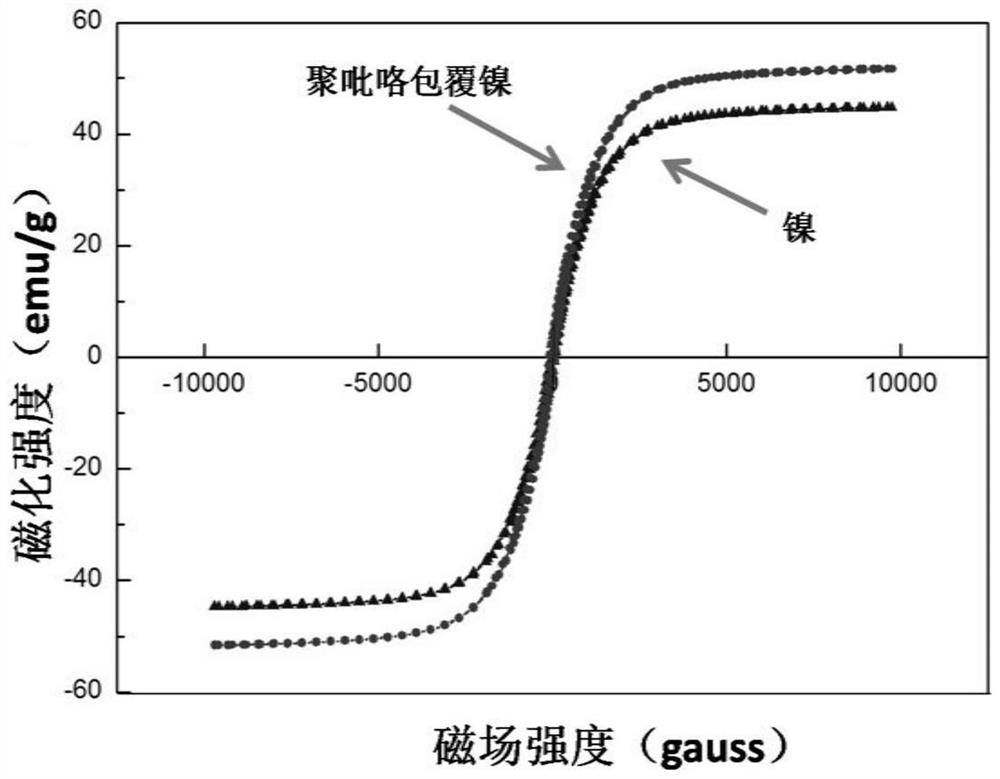

Conductive polymer composite material under the action of magnetic field and preparation method thereof

ActiveCN109722007ALow costGood compatibilityOrganic conductorsMetal/alloy conductorsConductive polymer compositeUltraviolet lights

The invention provides a conductive polymer composite material under the action of a magnetic field and a preparation method thereof, wherein the preparation method can effectively improve the conductivity of the obtained conductive polymer composite material. The preparation method comprises the following steps: (1) taking 0.1-0.3g of nickel powder and pyrrole monomer, adding 30-50mL of ethanol aqueous solution and 0.1-0.3g of sodium chloride, uniformly stirring, electrifying to polymerize pyrrole, purifying to obtain the poly-pyrrole coated nickel particles, wherein the molar ratio of nickelpowder to pyrrole monomer is (1:1) to (1:3); (2) uniformly mixing polyurethane acrylate resin, diethylene glycol monovinyl ether, 2-hydroxyl-2-methyl phenylacetone and the poly-pyrrole coated nickelparticles, arranging the mixture into a magnetic field with the magnetic field strength of 0.01-0.03 T, curing the polyurethane acrylate resin by using ultraviolet light, so as to obtain the conductive polymer composite material.

Owner:JIANGHAN UNIVERSITY

Method for catalytically synthesizing polycarboxylate superplasticizer by magnesium oxide, aluminum oxide or copper oxide

The invention discloses a method for catalytically synthesizing a polycarboxylate superplasticizer by magnesium oxide, aluminum oxide or copper oxide, which is characterized by comprising the following steps of: taking raw materials of a macromonomer, a micromonomer, a chain transfer agent, a reducing agent, an oxidizing agent, a catalyst and water, mixing the micromonomer with the water to prepare a solution A, mixing the reducing agent, the chain transfer agent and the water to prepare a solution B, wherein the macromonomer is Diethylene Glycol Monovinyl Ether, the catalyst is magnesium oxide, aluminum oxide or copper oxide; adding the macromonomer and water into a reactor, controlling the temperature to be 2-28 DEG C, adding the catalyst and the oxidizing agent, adding the solution A and the solution B dropwise, controlling the total time of dropwise adding and heat preservation reaction at the temperature of 2-28 DEG C to be 1-2 h, and preparing the polycarboxylate superplasticizer . The prepared polycarboxylate superplasticizer is particularly suitable for concrete preparation, has the characteristics of high dispersity, good slump retaining performance, high compressive strength, good durability and the like, and is high in practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

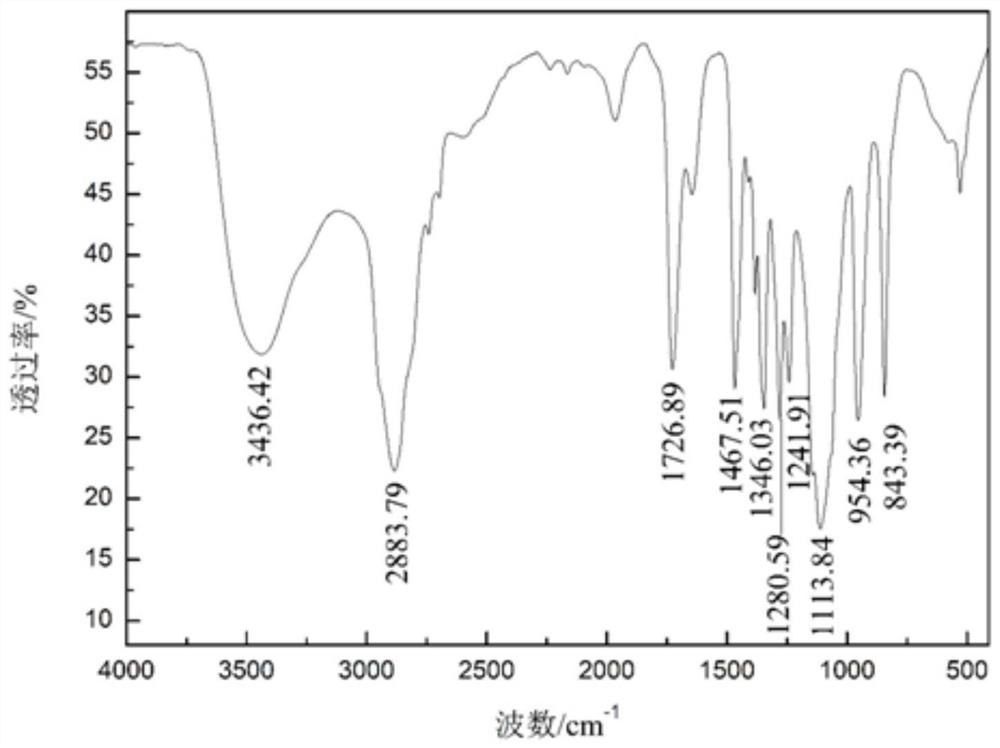

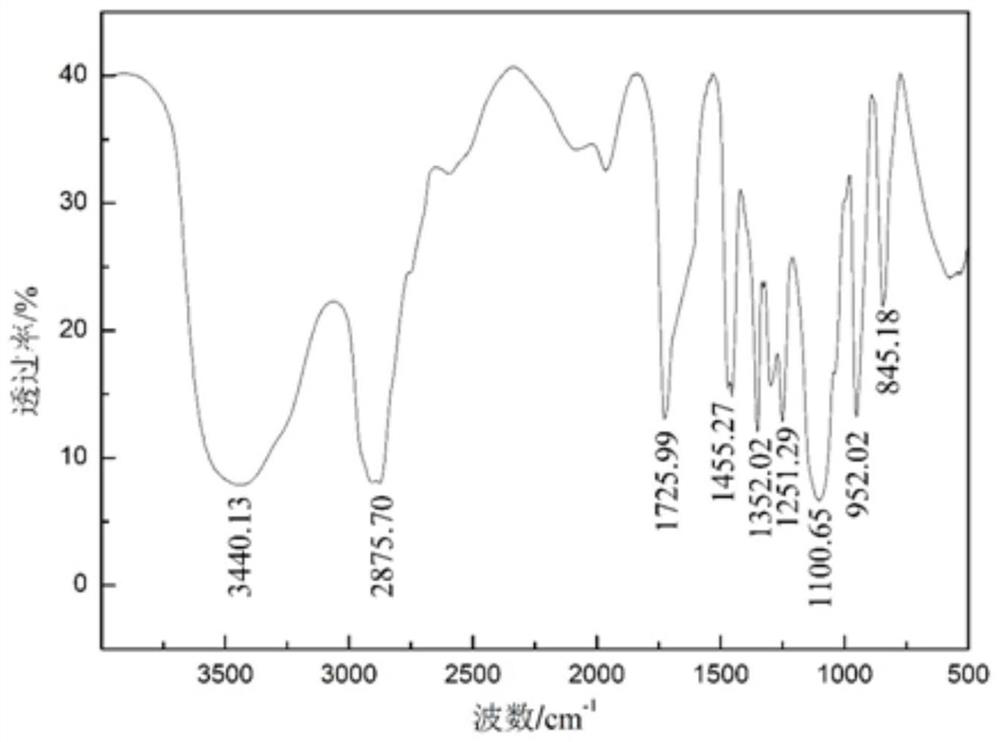

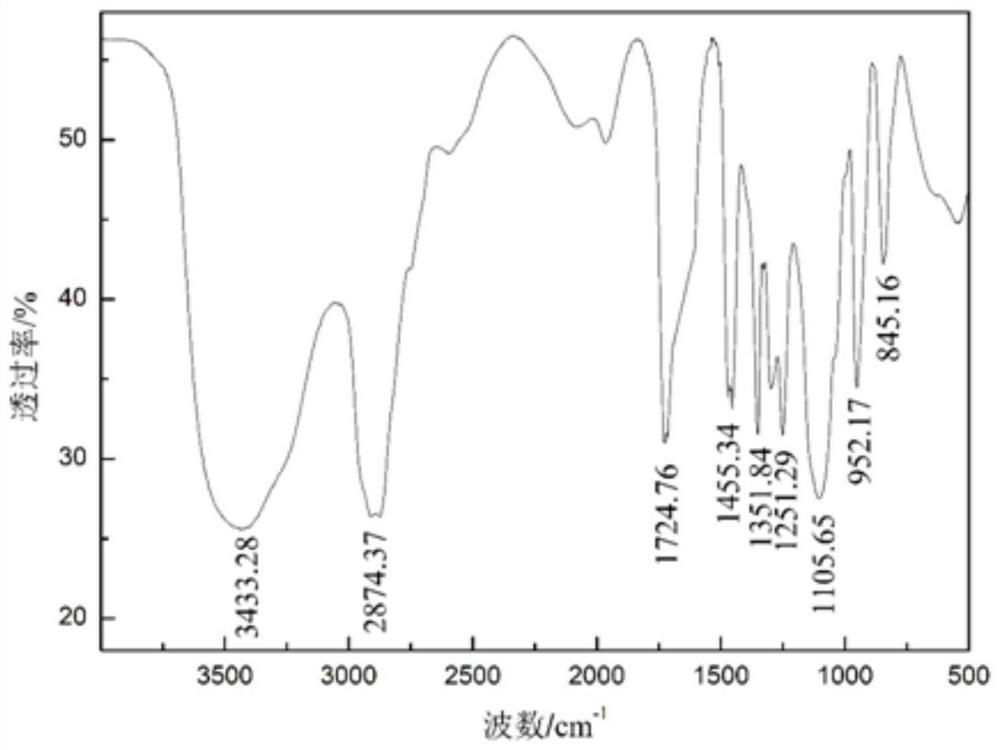

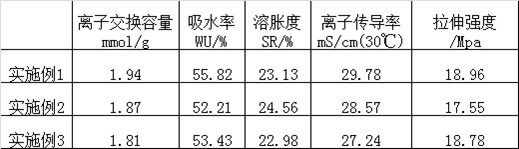

Alkaline anion exchange membrane for fuel cell and preparation method

The invention relates to an alkaline anion exchange membrane for a fuel cell and a preparation method of the alkaline anion exchange membrane. The membrane is prepared by the following steps: 1) reacting p-methylphenol and diethylene glycol monovinyl ether with hexachlorocyclotriphosphazene HCCP according to a certain ratio; 2) copolymerizing the product obtained in the step 1) and styrene according to different feeding ratios; 3) performing methyl bromination on the polymer in the step 2) by NBS; and 4) carrying out quaternization reaction on the polymer obtained in the step 3) by using tertiary amine, and alkalifying in a dilute sodium hydroxide solution to obtain the alkaline anion exchange membrane. According to the method, the main chain is free of heteroatoms, cyclotriphosphazene is grafted with high-density conduction sites, the alkali resistance and the conductivity are improved to a certain extent, the thermal stability is high, the used raw materials are simple and easy to obtain, and the operation is convenient.

Owner:安徽知凸凸科技服务有限公司

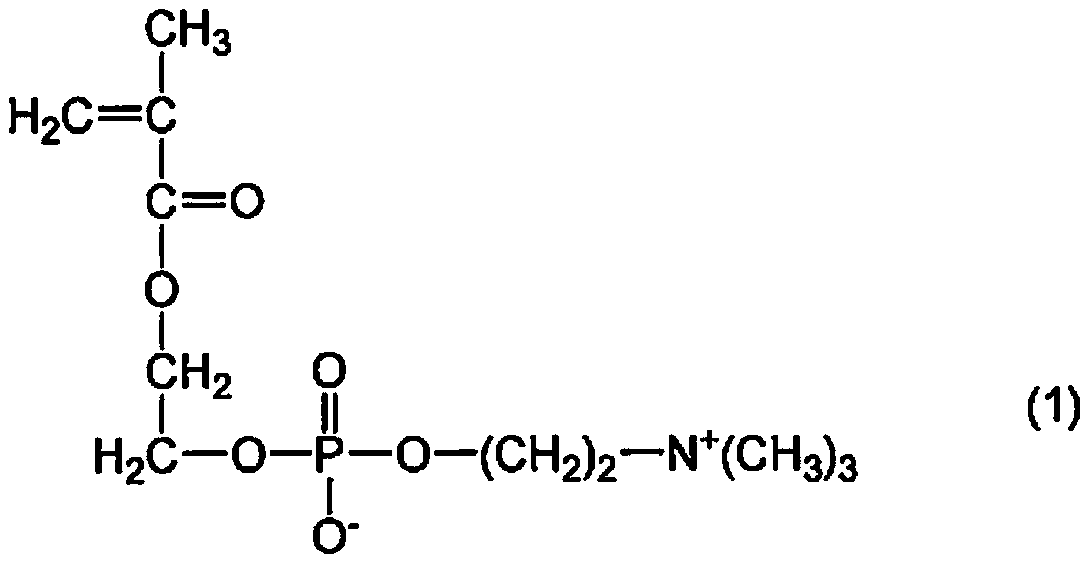

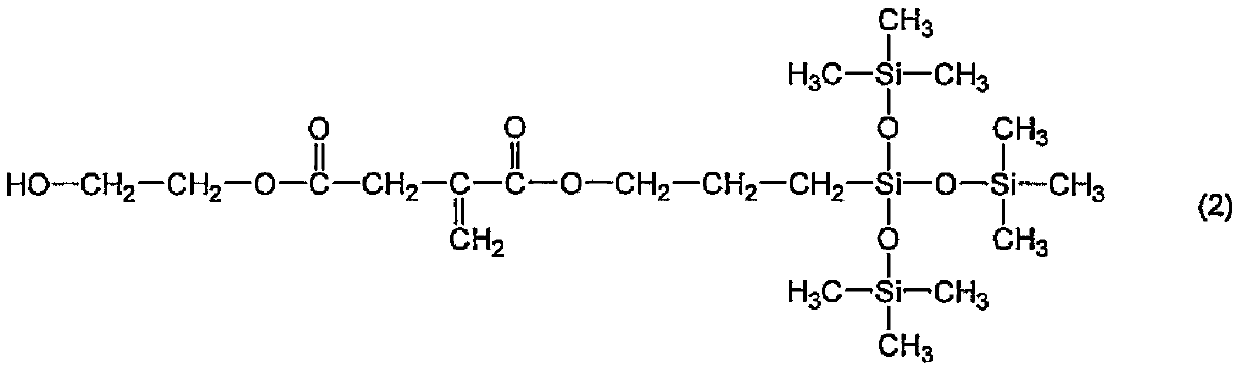

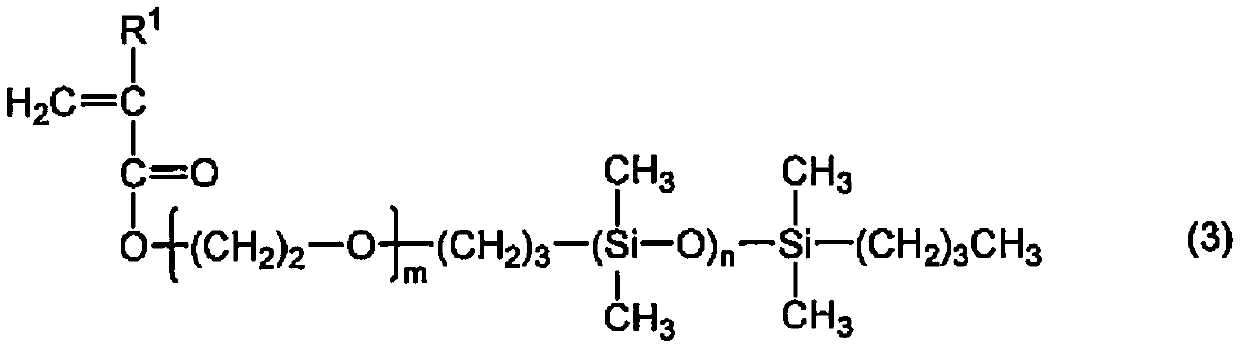

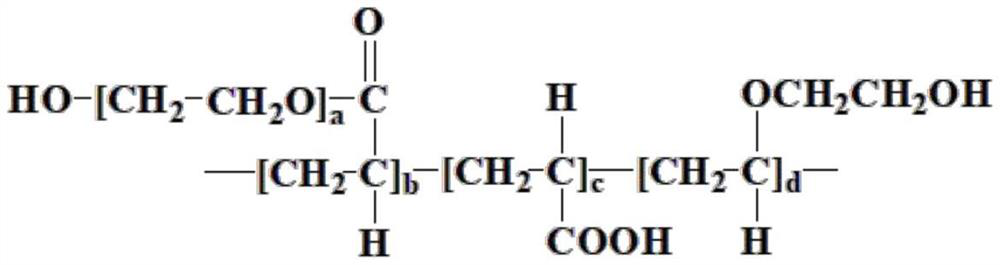

Monomer composition for contact lens, polymer for contact lens and production method thereof, and contact lens and production method thereof

ActiveCN110199219BStrong hydrophilic surfaceHigh oxygen permeabilityOptical partsVinyl etherMethacrylate

The present invention provides a monomer composition for contact lenses useful for producing contact lenses having excellent surface hydrophilicity, oxygen permeability, mechanical strength and wearing feeling. Further provided are a contact lens polymer obtained from the composition and a contact lens. The composition contains: a specific amount of (A) phosphorylcholine-containing methacrylate monomer; (B) selected from (meth)hydroxyethyl acrylate, (meth)hydroxypropyl acrylate, (meth) base) one or more hydroxyl-containing monomers in the group consisting of hydroxybutyl acrylate, hydroxyethyl acrylamide, ethylene glycol monovinyl ether and diethylene glycol monovinyl ether; (C) siloxane-containing (D) a siloxane-based (meth)acrylate; and (E) a crosslinking agent.

Owner:NOF CORP

A kind of highly adaptable polycarboxylate water reducer and its synthesis method

The invention discloses a highly adaptable polycarboxylate water-reducer and a method for synthesizing the water-reducer. Polyethylene glycol, a polymerization inhibitor, and acrylic acid are put into a reaction container in sequence for full stirring, and a catalyst is added into the container. Then react under heating conditions to generate polyester functional monomers; under normal temperature and pressure, use water as solvent, carry out ethylene glycol monovinyl ether, acrylic acid and composite initiators with the prepared polyester functional monomers Polymerization reaction to obtain polycarboxylate water reducer. The water reducer of the invention has simple structure, excellent performance, strong adaptability and is suitable for industrial promotion.

Owner:吉林省天宝建筑材料有限公司

Novel environment-friendly plasticizer

InactiveCN107739454AWith bactericidal functionWith insect repellent functionBiocidePest repellentsCopper oxidePalmitic acid

The invention discloses a novel environment-friendly plasticizer, which is prepared from 6 to 9 parts of 4-methoxyl-1,3-bis(4-chlorophenyl) phthalate, 20 to 32 parts of phthalic anhydride, 12 to 25 parts of 2-propyl-1-heptanol, 1 to 9 parts of filling materials, 13 to 19 parts of phytosterol, 19 to 30 parts of palmitic acid, 30 to 50 parts of gum rosin, 16 to 20 parts of organic solvents, 1 to 9 parts of zinc stearate, 8 to 13 parts of glass fiber powder, 5 to 9 parts of isopropanol, 10 to 16 parts of oxides and 9 to 14 parts of bonding agents; the organic solvents are prepared from perchloroethylene, ethylene glycol monovinyl ether and trolamine according to the mass ratio of (1 to 9):(6 to 10):(3 to 15); the oxides are prepared from copper oxide, iron trioxide, aluminum oxide and silveroxide according to the mass ratio of (6 to 15):(3.6 to 6.8): (1 to 3):(5.9 to 6.9). The novel environment-friendly plasticizer has the advantages of high stretching intensity and good bonding performance; certain fragrance can be released in the recipe; the sterilization and worm expelling functions are achieved; the enhancement effect is stable; the toxicity is reduced.

Owner:四川梅塞尔科技有限公司

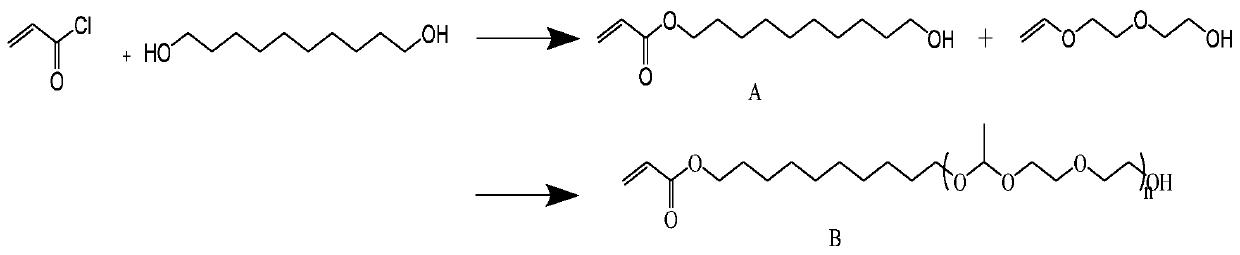

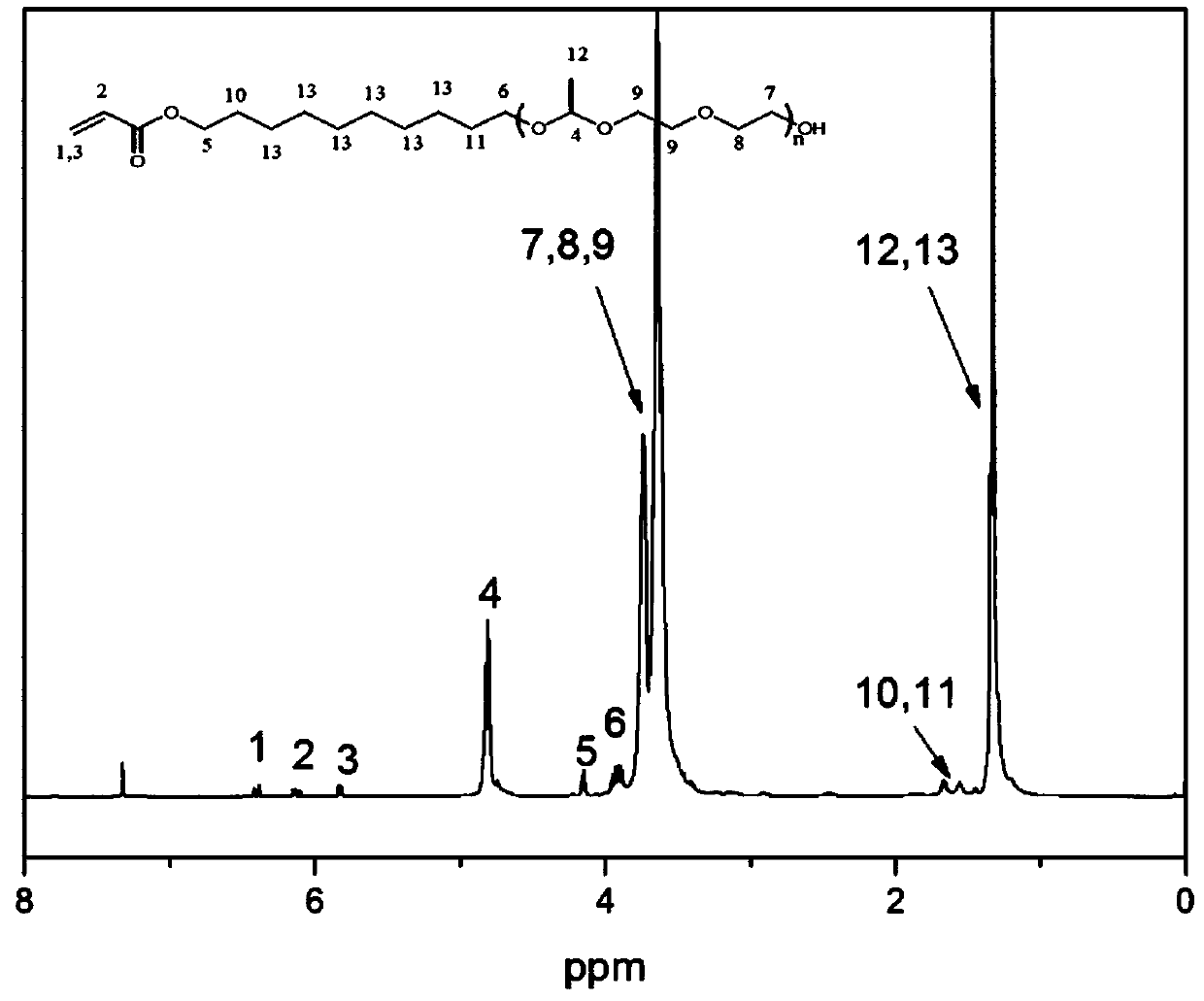

Polymerizable acid sensitive amphiphilic compound

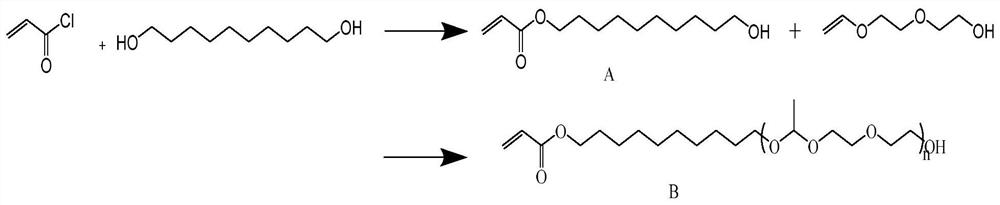

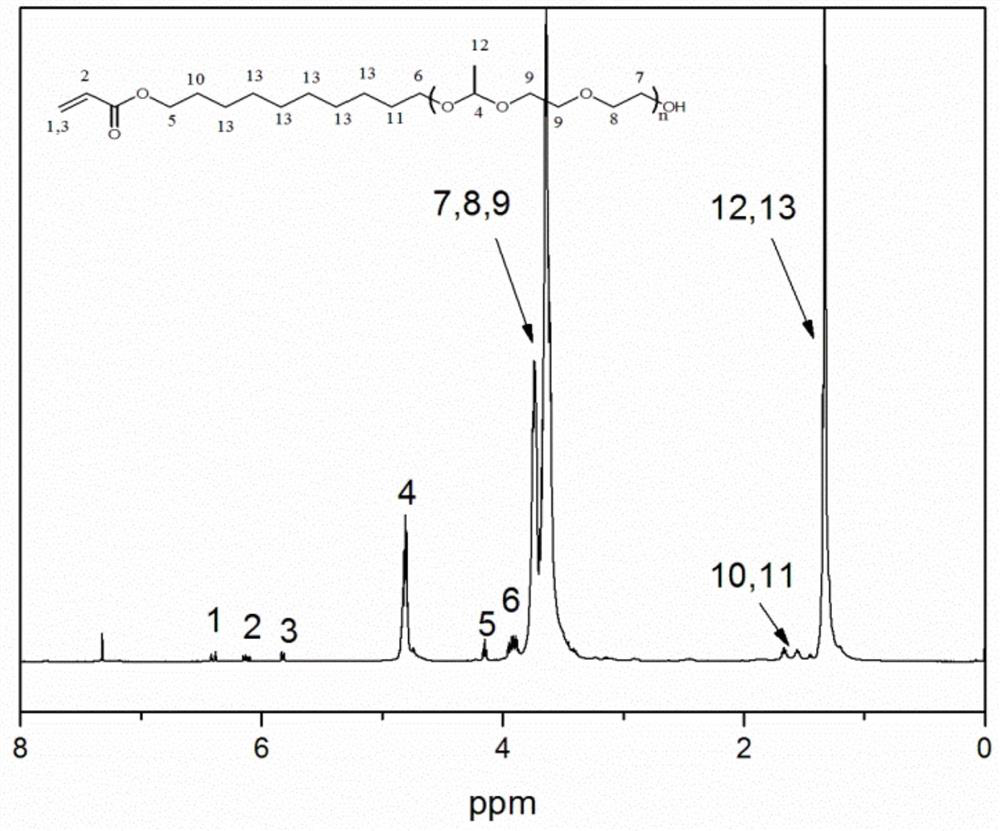

ActiveCN110330639AImprove solubilityGood compatibilityOrganic compound preparationCarboxylic acid esters preparationVinyl etherSolubility

The invention discloses a polymerizable acid sensitive amphiphilic compound, which is prepared from a substance C, a dihydric alcohol and di(ethylene glycol) vinyl ether as raw materials, p-toluenesulfonic acid as a catalyst and dichloromethane as a solvent by reaction in two steps, wherein the substance C is any one of acryloyl chloride, methacryloyl chloride and 2-ethylacryloyl chloride; the dihydric alcohol is any one of ethylene glycol, 1,3-propanediol, 1,4-butanediol, 1,5-pentanediol, 1,6-hexanediol, 1,7-heptadiol, 1,8-octanediol, 1,9-nonanediol and 1,10-decanediol; the acid-sensitive amphiphilic compound has one end of an oleophilic group and the other end of a hydrophilic group, are amphiphilic, have good solubility in both aqueous and oily solutions, and can self-assemble into nanomicelles in water; the acid-sensitive amphiphilic compound can degrade under acidic conditions, can be used as a drug carrier, and is particularly suitable for being used as a target carrier of someanticancer drugs; one end is double bond, and the polymerizable acid sensitive amphiphilic compound is easy to polymerize to generate new substances for use as medical materials.

Owner:THE EYE HOSPITAL OF WENZHOU MEDICAL UNIV +1

Method for synthesizing polycarboxylate superplasticizer through binary copolymerization of 6C polyether macromonomer under heterogeneous catalysis by cobalt oxide

The invention discloses a method for synthesizing a polycarboxylate superplasticizer through binary copolymerization of 6C polyether macromonomer under heterogeneous catalysis by cobalt oxide. The method is characterized by comprising the following steps: weighing raw materials including a macromonomer, a small monomer, a chain transfer agent, a reducing agent, an oxidizing agent, a catalyst and water, mixing the small monomers and the water to prepare a solution A, and mixing the reducing agent, the chain transfer agent and the water to prepare a solution B, adding the solution C into the solution B, wherein the macromonomer is diethylene glycol monovinyl ether; and adding the macromonomer and the water into a reactor with a thermometer, controlling a temperature to be 0-20 DEG C, adding the catalyst and the water, conducting stirring and mixing, adding the oxidizing agent and the water, performing mixing and stirring, dropwise adding the solution A and the solution B at a constant speed at the same time, and carrying out a heat-preserved reaction, wherein the total time of dropwise addition and reaction is 1-2 hours. The polycarboxylate superplasticizer prepared through binary copolymerization of 6C polyether macromonomer under heterogeneous catalysis by cobalt oxide is especially suitable for concrete preparation, and has the advantages of excellent cement dispersion performance and aging slump retaining performance, good compressive strength and durability, and strong practicability.

Owner:SICHUAN TONGZHOU CHEM TECH +1

Finish paint for wood

The invention discloses finish paint for wood. The finish paint for wood is prepared from components in parts by weight as follows: 10-20 parts of phthalic anhydride, 10-20 parts of fatty acid, 1-5 parts of nano-silica, 5-7 parts of ethanol, 2-10 parts of ferric oxide, 5-15 parts of triethyl citrate, 0.2-0.9 parts of a dispersing agent, 0.2-0.9 parts of citric acid, 1-2 parts of a thickening agent, 0.2-0.5 parts of a defoaming agent, 1-5 parts of styrene, 1-5 parts of perchloroethylene, 1-5 parts of trichloroethylene and 1-5 parts of ethylene glycol monovinyl ether. The finish paint for wood has beneficial effects as follows: 1, wear resistance is good; 2, adhesive force is strong, and the finish paint is not prone to falling off under collision and vibration during using; 3, the finish paint is environmentally friendly.

Owner:芜湖益承木业包装有限公司

12-crown ether-4 lithium salt complex and its preparation method and application

ActiveCN113248468BReasonable designRaw materials are safe and easy to obtainSulfonic acids salts preparationVinyl etherBiochemical engineering

The invention discloses a 12-crown ether-4 lithium salt complex and a preparation method thereof, as well as a method for preparing 12-crown ether-4 by using the complex. The preparation method of the described 12-crown ether-4 takes the compound of formula 1 triethylene glycol monovinyl ether as a raw material, and the compound of formula 2 contains substituent lithium alkoxide under the condition of isolated air, in the first reaction solvent , adding a basic substance to catalyze the reaction, and after the reaction is complete, the compound 12-crown-4 lithium salt complex of formula 3 is obtained; then the compound 12-crown-4 lithium salt complex of formula 3 and the acidic substance are added to the second reaction In a solvent, react at a reaction temperature of -20 to 100°C. After the reaction is complete, the compound 12-crown ether-4 of formula 4 is obtained. The design route of the invention is reasonable, the raw materials are safe and easy to obtain, the process safety is high, the reaction selectivity is high, the product purity is high, the operator is friendly, the production cost is greatly reduced, and the demand for industrial production of products can be fully met.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

Reinforcing method for glass product

The invention discloses a reinforcing method for a glass product. The reinforcing method includes the following steps that the glass product is placed into a preheating chamber in the constant temperature state and preheated; vinyl triethoxy silane and ethylene glycol monovinyl ether are selected, the vinyl triethoxy silane is put into the ethylene glycol monovinyl ether and dissolved, and a vinyltriethoxy silane solution, namely, a soaking solution is obtained; mixed liquid jointly composed of a potassium chloride solution, titanium tetrachloride and an alcohol solvent and potassium glutamate are mixed and stirred, and an electrolyte is finally formed; the preheated glass product is immersed into the soaking solution for soaking; the soaked glass product is taken out, put into the electrolyte for electrolysis, taken out of the electrolyte after electrolysis, washed with fresh water, and naturally aired. By means of the reinforcing method, the glass product is not prone to breakage bycollision with external objects in the use process, and the steps and the flow of the whole reinforcing method are easy and facilitate execution and operation.

Owner:重庆市笙建玻璃有限公司

A special grinding aid for Raymond mill

The invention belongs to the technical field of cement admixtures, and especially relates-a special grinding aid for a Raymond mill. The special grinding aid is prepared from, by weight, 45-60 parts of hydramine, 10-20 parts of glycerol, 5-15 parts of diethylene glycol, 8-20 parts of lignosulfonate, 3-10 parts of phosphate, 2-9 parts of monododecyl phosphate and 3-10 parts of ethylene glycol monovinyl ether; and the hydramine is a mixture of diethanolisopropanolamine and ethanoldipropanolamine. When a Raymond mill mineral admixture is used, the special grinding aid for the Raymond mill is added to significantly improve the material fluidity, improve the grinding efficiency of the mill, increase the output per machine hour of the mill and reduce the electricity consumption in production; and the special grinding aid can improve the active index and the fluidity of mineral components in every age, and has a good compatibility with water reducers.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

A polymerizable acid-sensitive amphiphilic compound

ActiveCN110330639BGood dispersionFull responseOrganic compound preparationCarboxylic acid esters preparationVinyl etherPolymer science

The invention discloses a polymerizable acid-sensitive amphiphilic compound, which is divided into two parts by using substance C, glycol and diethylene glycol monovinyl ether as raw materials, using p-toluenesulfonic acid as a catalyst, and dichloromethane as a solvent. The reaction is carried out in one step; wherein the substance C is any one of acryloyl chloride, methacryloyl chloride, and 2-ethacryloyl chloride; the dibasic alcohol is ethylene glycol, 1,3-propylene glycol, 1,4-butanediol, Any one of 1,5-pentanediol, 1,6-hexanediol, 1,7-heptanediol, 1,8-octanediol, 1,9-nonanediol and 1,10-decanediol Acid-sensitive amphiphilic compound, one end is a lipophilic group, the other end is a hydrophilic group, has amphiphilicity, has good solubility in aqueous solution and oily solution, and can self-assemble in water Nano-micelle; can degrade under acidic conditions; can be used as a drug carrier, especially suitable as a targeting carrier for some anti-cancer drugs; one end is a double bond, which is prone to polymerization and generates new substances, which can be used as medical materials.

Owner:THE EYE HOSPITAL OF WENZHOU MEDICAL UNIV +1

A conductive polymer composite material under the action of a magnetic field and its preparation method

ActiveCN109722007BLow costGood compatibilityOrganic conductorsMetal/alloy conductorsVinyl etherPolymer science

The invention provides a conductive polymer composite material under the action of a magnetic field and a preparation method thereof. The preparation method can effectively improve the conductivity of the obtained conductive polymer composite material. The preparation method includes the following steps: (1) Take 0.1-0.3g of nickel powder and pyrrole monomer, add 30-50mL of ethanol aqueous solution and 0.1-0.3g of sodium chloride, stir evenly, then energize pyrrole to polymerize, and obtain poly Pyrrole-coated nickel particles, wherein the molar ratio of nickel powder to pyrrole monomer is (1:1) to (1:3); (2) polyurethane acrylate resin, diethylene glycol monovinyl ether, 2-hydroxy ‑2‑methylpropiophenone and the polypyrrole-coated nickel particles are uniformly mixed and then placed in a magnetic field with a magnetic field strength of 0.01‑0.03T, and the polyurethane acrylate resin is cured with ultraviolet light to obtain the conductive polymer composite Material.

Owner:JIANGHAN UNIVERSITY

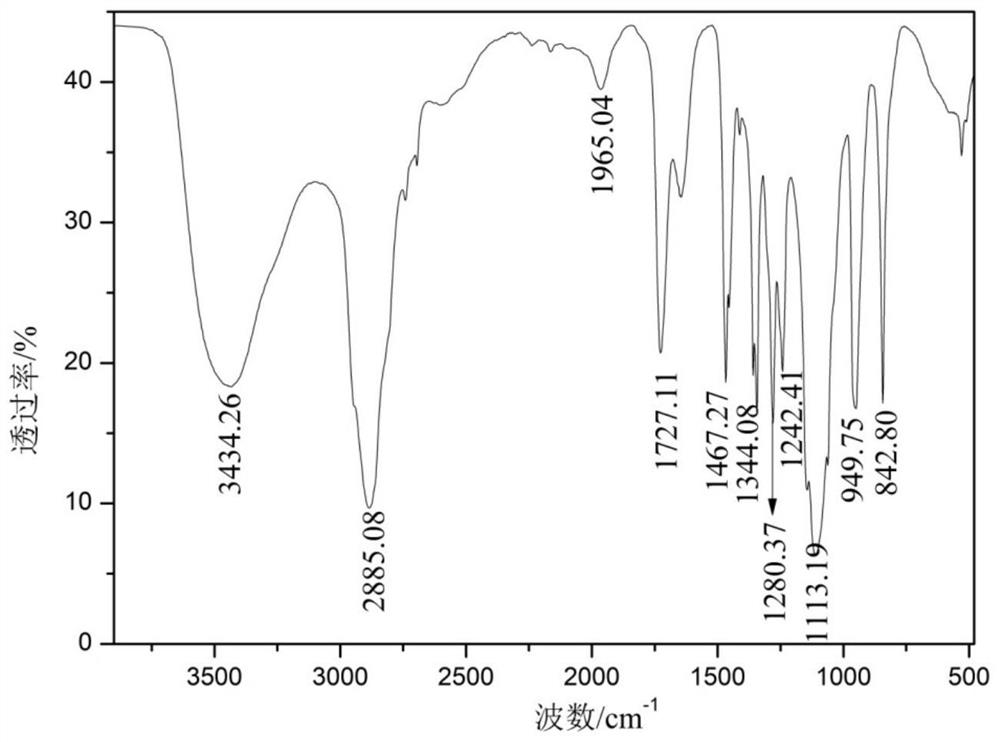

Hydrophilic UV photocuring monomer, aqueous emulsion and preparation methods of hydrophilic UV photocuring monomer and aqueous emulsion

PendingCN113372203AImprove hydrophilicityAvoid breakingEther preparation from oxiranesVinyl etherPolymer science

The invention relates to preparation methods for a hydrophilic UV photocuring monomer and an aqueous emulsion thereof. The hydrophilic UV photocuring monomer is prepared from bisphenol A polyoxyethylene ether, epoxy chloropropane, ethylene glycol monovinyl ether, potassium hydroxide, sodium hydroxide, a polymerization inhibitor and a catalyst. The structural formula of the hydrophilic UV photocuring monomer is shown in the specification. In the structural formula, n is in a range of 2-4. Thus, on the basis of keeping the original strength of bisphenol A type photocuring resin, an ethyoxyl group is introduced, so toughness is enhanced, and the resin is not easy to break and fall off; and hydrophilic ether bonds and hydroxyl groups are introduced, so the hydrophilicity of the photocuring monomer is enhanced, a low-VOC aqueous emulsion is easy to prepare, and the prepared aqueous emulsion is good in stability.

Owner:ZHEJIANG HUANGMA TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com