Preparation method and production system of ethylene glycol monovinyl ether

A technology of ethylene glycol monovinyl ether and production system, which is applied in ether preparation, unsaturated compound addition to prepare ether, organic chemistry, etc., can solve problems such as low efficiency, avoid by-products, reduce operation difficulty, design scientifically sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

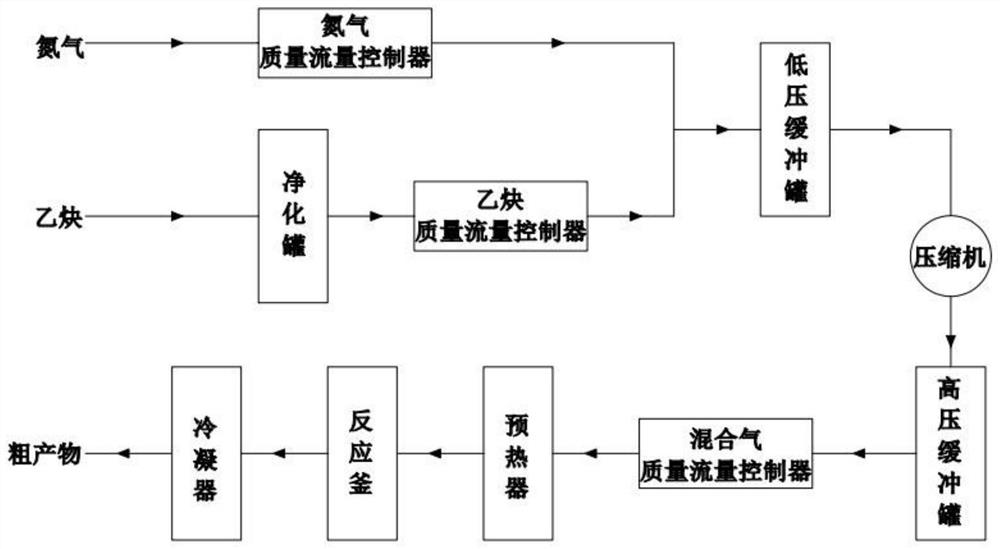

[0035] A kind of preparation method of ethylene glycol monovinyl ether, its technological process is as figure 1 As shown, it specifically includes the following steps:

[0036] S1. Add the catalyst and ethylene glycol into the high-pressure gas-liquid mass transfer reactor, and pass inert gas to replace the air in all equipment and pipelines; the reactor is turned on and stirred and heated to the reaction temperature T1, and vacuum dehydration is carried out. Make the water content of the system lower than 10ppm;

[0037] S2. Pass acetylene and inert gas into the reaction kettle through the compressor, so that the pressure in the kettle reaches the initial reaction pressure P1; as the reaction progresses, the acetylene is continuously consumed, and the pressure in the kettle drops slowly during the reaction. When the pressure in the kettle After keeping stable, open the condensation valve between the reactor and the condenser;

[0038] S3. Adjust the temperature in the kett...

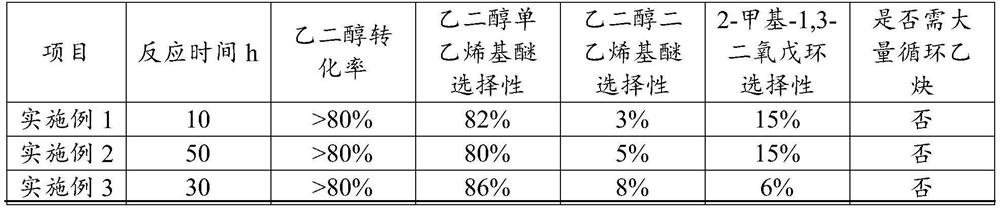

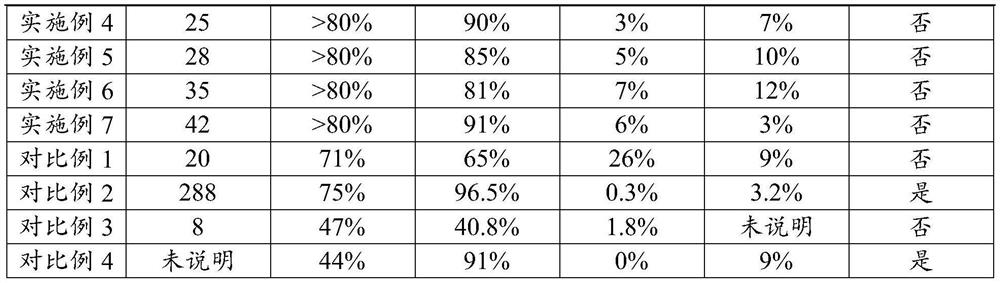

Embodiment 1

[0046] A preparation method of ethylene glycol monovinyl ether, comprising the following steps:

[0047] Add 1500g (24.2mol) ethylene glycol and 78.8g potassium hydroxide into the reaction kettle, stir and raise the temperature to 150°C, and vacuum dehydrate for 2h. Acetylene and nitrogen are passed into the reactor at a volume ratio of 1:1, so that the initial reaction pressure reaches 1.0 MPa. After the pressure in the kettle no longer drops within 30 minutes, open the condensation valve of the reactor and the condenser, adjust the temperature in the kettle to 120°C, and feed nitrogen gas into the bottom of the reactor at a rate of 130 L / h for 30 minutes. Close the condensation valve of the reactor and the condenser, readjust the temperature in the reactor to 150°C, and then pass acetylene and nitrogen into the reactor at a volume ratio of 1:1, so that the initial reaction pressure reaches 1.0MPa again, and repeat the above process. When the total input amount of acetylene...

Embodiment 2

[0050] A preparation method of ethylene glycol monovinyl ether, comprising the following steps:

[0051] Add 1500g (24.2mol) of ethylene glycol and 7.5g of potassium hydroxide into the reaction kettle, stir and raise the temperature to 180°C, and vacuum dehydrate for 2h. Acetylene and nitrogen are passed into the reactor at a volume ratio of 4:1, so that the initial reaction pressure reaches 0.4MPa. After the pressure inside the kettle no longer drops within 30 minutes, open the condenser valves of the reactor and the condenser, adjust the temperature inside the kettle to 160°C, and feed nitrogen gas into the bottom of the reactor at a rate of 60 L / h for 30 minutes. Close the condensation valve of the reactor and the condenser, readjust the temperature in the reactor to 180°C, and then pass acetylene and nitrogen into the reactor at a volume ratio of 4:1, so that the initial reaction pressure reaches 0.4MPa again, and repeat the above process. When the total input amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com