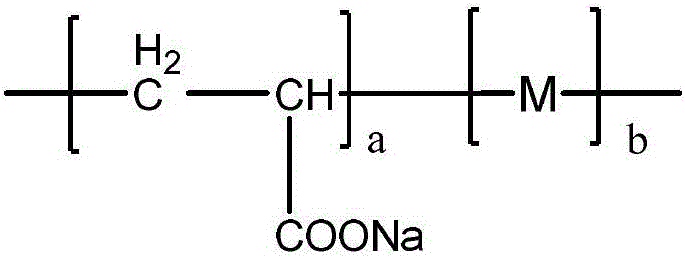

Polycarboxylate water reducer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of building materials, can solve the problems of complex production process of initiator, poor mud resistance of water reducing agent, high cost, etc., and achieve high double bond retention rate, high water reducing rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

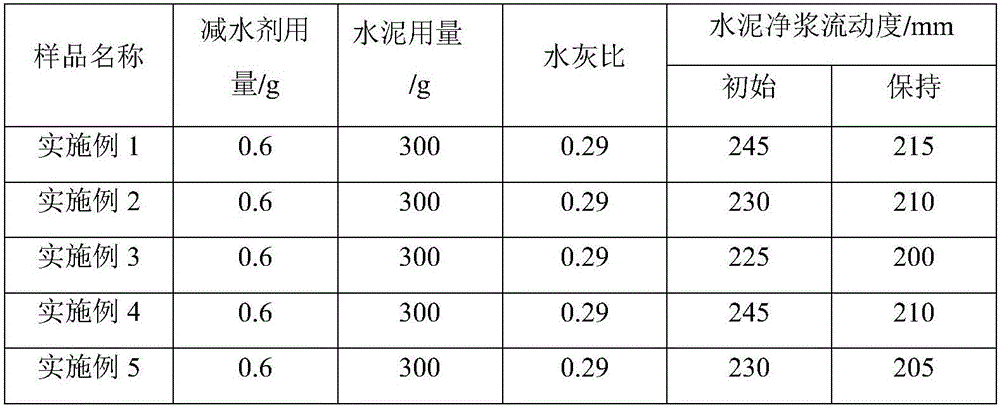

Examples

Embodiment 1

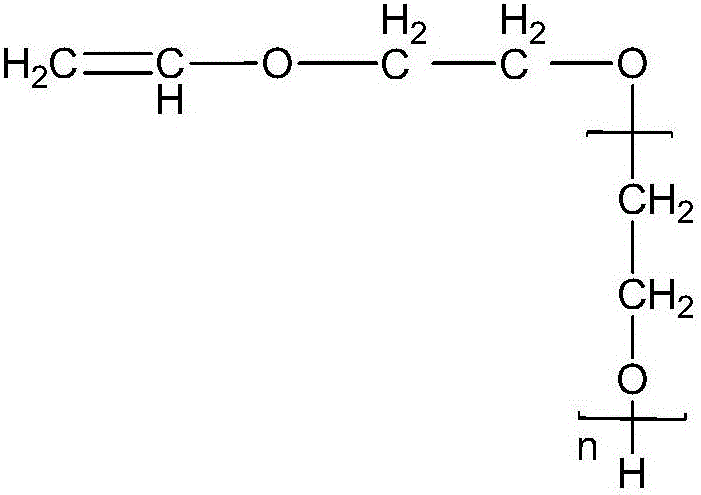

[0028] 1) Preparation of EPEG-2300 macromonomer

[0029] Add 20g of ethylene glycol monovinyl ether and 0.2g of sodium methoxide into a beaker, and stir evenly. Into the closed 1L autoclave, inject the mixed solution of ethylene glycol monovinyl ether and sodium methoxide. Close the reactor, heat up to 100°C, and start to feed ethylene oxide gas. Control the temperature of the reactor to not be higher than 110°C, continue the reaction for 6 hours, and feed about 520 g of ethylene oxide gas in total, then stop feeding the ethylene oxide gas and lower the temperature of the reactor. The product is released after cooling down, and it becomes a white waxy solid after cooling, which is an EPEG macromonomer with an average molecular weight of 2300.

[0030] 2) Preparation of polycarboxylate water reducer

[0031] In a 500ml reaction bottle equipped with a stirrer and a condenser, add 100g of EPEG-2300 macromonomer into 60g of deionized water, heat properly and fully dissolve to m...

Embodiment 2

[0033] 1) Preparation of EPEG-2300 macromonomer

[0034] The preparation method of EPEG-2300 macromonomer is the same as in Example 1.

[0035] 2) Preparation of polycarboxylate water reducer

[0036] In a 500ml reaction bottle equipped with a stirrer and a condenser, add 100g of EPEG-2300 macromonomer into 60g of deionized water, heat properly and fully dissolve to make a reaction bottom liquid; add 0.15g of vitamin C, 8.7g of acrylic acid, Add 0.80 g of 40 g of deionized water in turn, mix and stir evenly, and prepare a drop solution; control the reaction temperature at 20-25 °C, and add 1.0 g of H 2 o 2 , and then drop the dripping liquid at a constant speed, and the dropwise addition is completed in 3 hours; after continuing the heat preservation reaction for 1 hour, add a solution made of 5g NaOH and 60g water, and stir evenly to obtain a polycarboxylate superplasticizer.

Embodiment 3

[0038] 1) Preparation of EPEG-3500 macromonomer

[0039] Add 15g of ethylene glycol monovinyl ether and 0.3g of sodium methoxide into a beaker, and stir evenly. Into the closed 1L autoclave, inject the mixed solution of ethylene glycol monovinyl ether and sodium methoxide. Close the reactor, heat up to 100°C, and start to feed ethylene oxide gas. Control the temperature of the reactor to not be higher than 110°C, continue the reaction for 8 hours, and feed about 600 g of ethylene oxide gas in total, then stop feeding the ethylene oxide gas and lower the temperature of the reactor. The product is released after cooling down, and it becomes a white waxy solid after cooling, which is an EPEG macromonomer with an average molecular weight of 3500.

[0040] 2) Preparation of polycarboxylate water reducer

[0041] In a 500ml reaction bottle equipped with a stirrer and a condenser, add 100g of EPEG-3500 macromonomer into 60g of deionized water, heat properly and fully dissolve to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com