A conductive polymer composite material under the action of a magnetic field and its preparation method

A technology of conductive polymer and composite material, applied in the field of conductive polymer composite material and its preparation under the action of a magnetic field, can solve the problem that the conductive performance of the conductive polymer composite material needs to be further improved, and achieves increased conductivity, reduced cost, and improved operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the first aspect of the present invention, an embodiment of the present invention provides a method for preparing a conductive polymer composite material under the action of a magnetic field, comprising the following steps:

[0028] (1) Take 0.1-0.3g of nickel powder and pyrrole monomer, add 30-50mL of ethanol aqueous solution and 0.1-0.3g of sodium chloride, stir evenly, and then energize pyrrole to polymerize, and obtain polypyrrole-coated nickel particles after purification, wherein, The molar ratio of nickel powder to pyrrole monomer is (1:1)-(1:3), and the ethanol aqueous solution is obtained by mixing water and ethanol with a volume ratio of (1:1)-(1:3);

[0029] (2) After mixing polyurethane acrylate resin, diethylene glycol monovinyl ether, 2-hydroxyl-2-methylpropiophenone and the polypyrrole-coated nickel particles, place them in a magnetic field with a strength of 0.01-0.03T In the magnetic field, the urethane acrylate resin is cured with ultravio...

Embodiment 1

[0048] Embodiment 1: Prepare conductive polymer composite material with polyurethane acrylate resin and polypyrrole-coated nickel particles

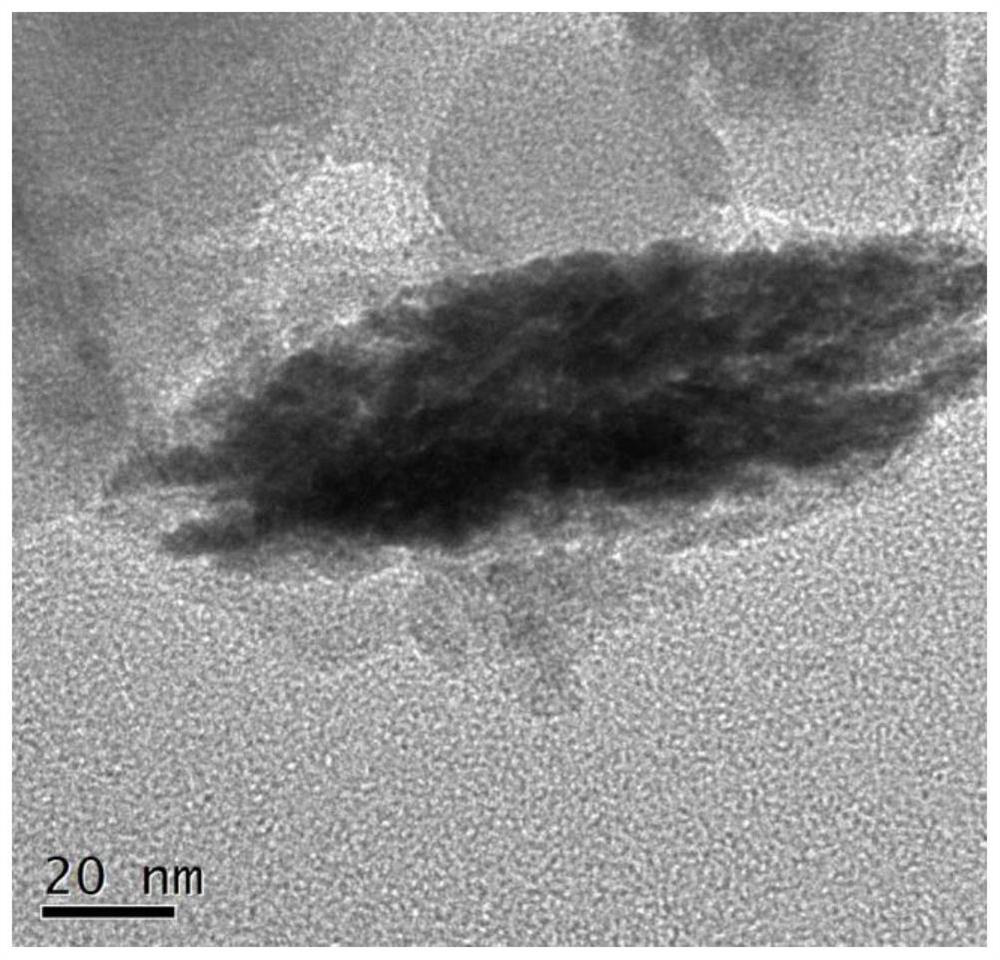

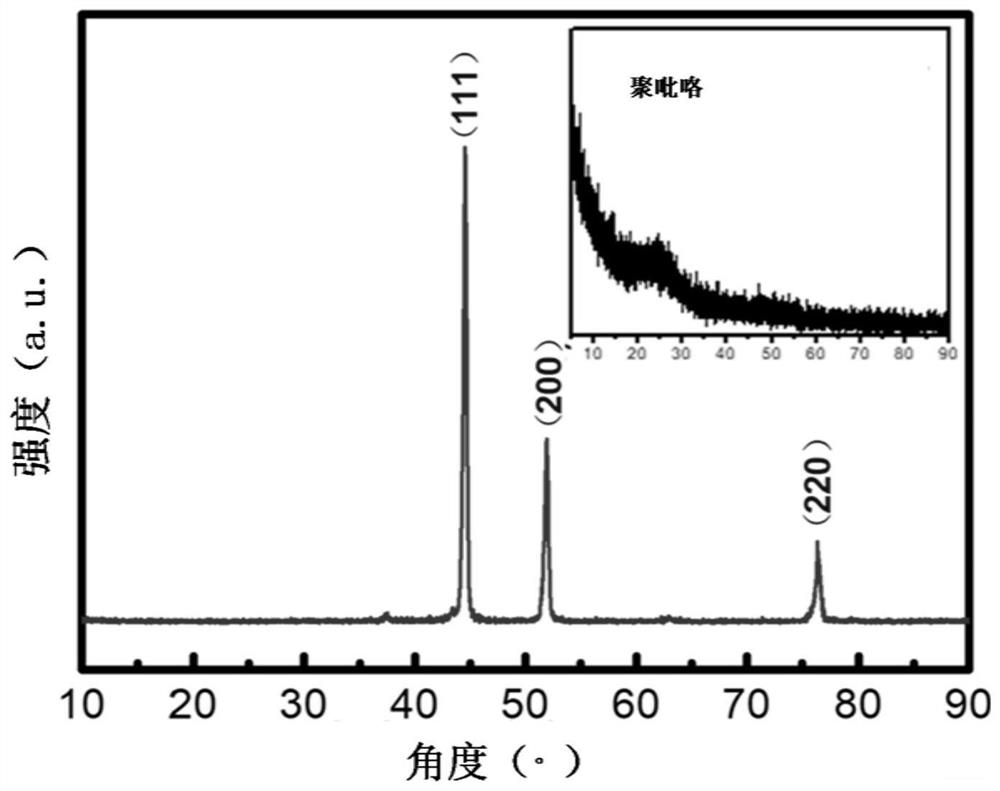

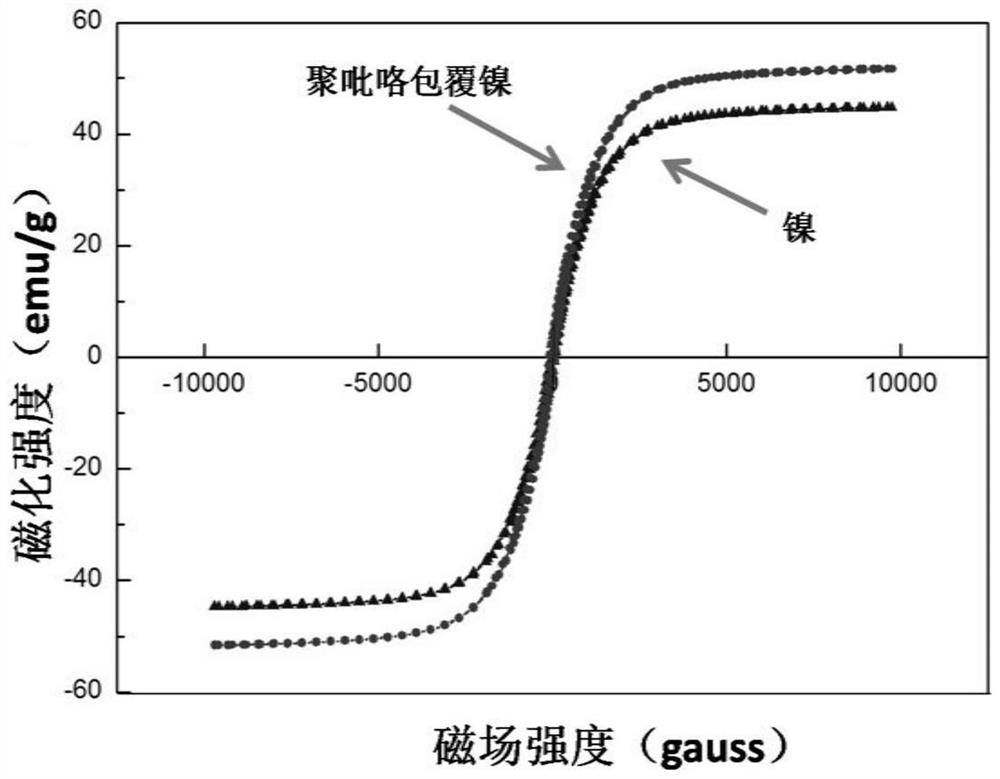

[0049] (1) Put nickel powder with a particle size of 0.1-1mm and pyrrole monomer in a molar ratio of 1:1. Take 0.3g of nickel powder and pyrrole monomer in a beaker, add 50mL of ethanol aqueous solution with a volume ratio of water and ethanol of 1:1 , and then add 0.2g of sodium chloride, stir evenly and the current density is 2.0mA·cm -2 Direct current for 10 minutes, take out the composite material, add ethanol and centrifuge, take the solid and place it in an oven at 80°C to dry to obtain polypyrrole-coated nickel particles.

[0050](2) Get 3g polyurethane acrylate resin in the beaker, then take the quality of polyurethane acrylic resin as a benchmark, add 10% diethylene glycol monovinyl ether, 5% 2-hydroxyl-2-methylpropiophenone, 1 % of the polypyrrole-coated nickel particles prepared in step (1), stirred evenly, placed in a magnet...

Embodiment 2

[0057] Example 2: Preparation of conductive polymer composite material with polyurethane acrylate resin and polypyrrole-coated nickel particles

[0058] (1) Put nickel particles with a particle size of 0.1-1mm and pyrrole monomer in a molar ratio of 1:3 to take 0.3g of nickel powder and pyrrole monomer in a beaker, add 50mL of ethanol aqueous solution with a volume ratio of water and ethanol of 1:1 , and then add 0.2g of sodium chloride, stir evenly and the current density is 2.0mA·cm -2 Direct current for 10 minutes, take out the composite material, add ethanol and centrifuge, take the solid and place it in an oven at 80°C to dry to obtain polypyrrole-coated nickel particles.

[0059] (2) Get 3g polyurethane acrylate resin in the beaker, then take the quality of polyurethane acrylic resin as a benchmark, add 10% diethylene glycol monovinyl ether, 5% 2-hydroxyl-2-methylpropiophenone, 1 % of polypyrrole-coated nickel particles prepared in the first step, stirred evenly, placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com