12-crown ether-4 lithium salt complex as well as preparation method and application thereof

A complex, crown ether technology, applied in sulfonate preparation, organic chemistry and other directions, can solve the problems of high raw material risk, low product yield, low product purity, etc., and achieve high reaction selectivity and high product purity. , the effect of high process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

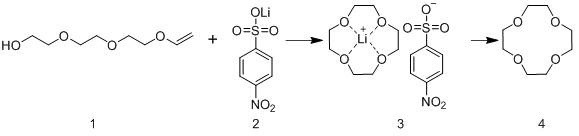

[0033] The synthetic route is as follows:

[0034]

[0035] Step (1): Preparation of formula 3 compound 12-crown-4 p-nitrobenzenesulfonate lithium complex

[0036] Maintain a slight positive pressure of nitrogen, and add 60 L of toluene, 6.31 kg of formula 2 compound lithium p-nitrobenzenesulfonate, 5.29 kg of formula 1 compound triethylene glycol monovinyl ether, and stir well in the 100L reactor; 5 L of 2M lithium tert-butoxide tetrahydrofuran solution was added to the reaction solution, and stirred at room temperature for 1 hour. The temperature of the reaction solution was raised to 70° C. for 6 hours, and the reaction was completed.

[0037] The reaction solution was naturally cooled to room temperature, and a large amount of light yellow solid was precipitated. Filtrate, recover the filtrate for mechanical application, and dry the filter cake to obtain 11.32 kg of product. Product HPLC purity 99.1%, yield 97.84%, 1H NMR (400MHz, d6-DMSO): δ8.43 (d, 2H), 8.02 (d, 2H...

Embodiment 2

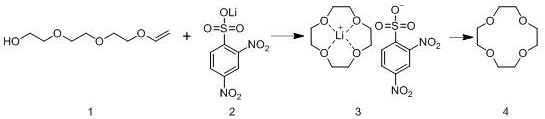

[0044] The synthetic route is as follows:

[0045]

[0046] Step (1): Preparation of 12-crown-4 (2,4-dinitrobenzenesulfonate lithium) complex compound of formula 3

[0047] Maintain a slight positive pressure of nitrogen, add 50 L tetrahydrofuran, 8.05 kg formula 2 compound 2,4-dinitrobenzene sulfonate lithium, 5.29 kg formula 1 compound triethylene glycol monovinyl ether, and stir and then add 300 g of sodium ethylate in three batches to the reaction solution, and stir at room temperature for 1 hour. The temperature of the reaction solution was raised to 40° C. for 7 hours, and the reaction was completed.

[0048] The reaction solution was naturally cooled to room temperature, and a large amount of light yellow solid was precipitated. Filtrate, recover the filtrate for mechanical application, and dry the filter cake to obtain 12.01kg of product. Product HPLC purity 98.2%, yield 93%, 1H NMR (400MHz, d6-DMSO): δ9.07(s, 1H), 8.91(d, 1H), 8.34 (d, 1H), 3.77(s, 16H) .

[0...

Embodiment 3

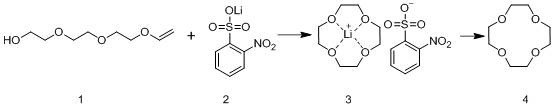

[0055] The synthetic route is as follows:

[0056]

[0057] Step (1): Preparation of Formula 3 Compound 12-Crown Ether-4 o-Nitrobenzenesulfonate Lithium Complex

[0058] Maintaining a slight positive pressure of nitrogen, add 45 L of xylene, 7.31 kg of formula 2 compound o-nitrobenzene sulfonate lithium, 5.29 kg of formula 1 compound triethylene glycol monovinyl ether, and stir well; Add 200 g of sodium methoxide in four batches to the reaction solution, and stir at room temperature for 1 hour. The temperature of the reaction solution was raised to 45° C. for 5 hours, and the reaction was completed.

[0059] Most of the solvent was recovered by rotary evaporation of the reaction solution, and an appropriate amount of tert-butyl methyl ether was added to the residue, cooled in an ice-water bath to precipitate a large amount of light yellow solid. Filtrate, recover the filtrate and apply mechanically, and dry the filter cake to obtain 10.64kg of product. Product HPLC purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com