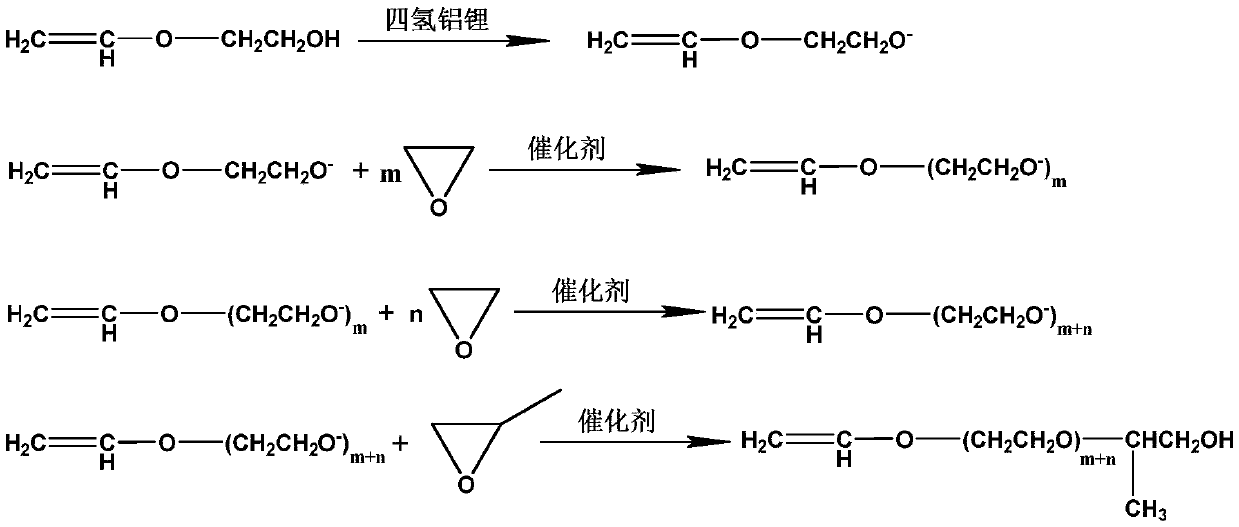

Preparation method of polycarboxylic acid water reducer macromonomer ethylene glycol monovinyl polyoxyethylene ether

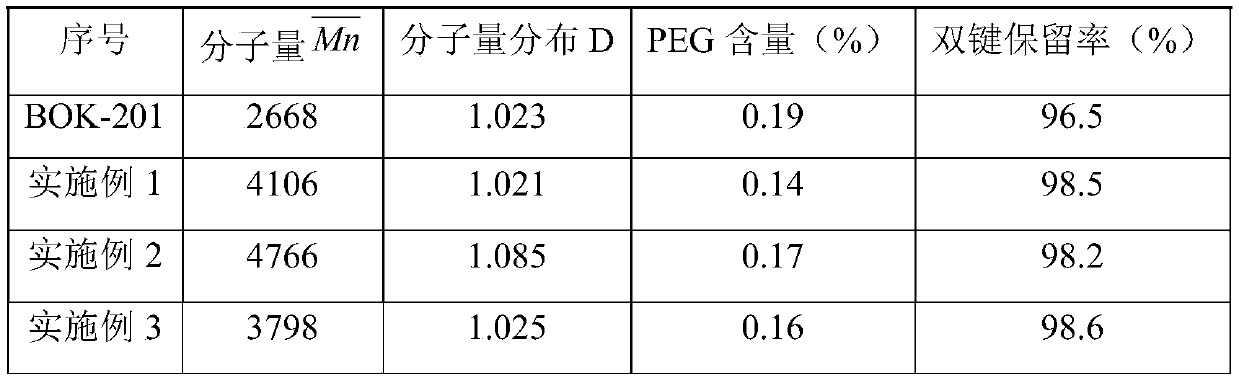

A technology of ethylene glycol monovinyl polyoxyethylene ether and ethylene glycol monovinyl ether is applied in the field of preparation of polycarboxylate water reducing agent macromonomer ethylene glycol monovinyl polyoxyethylene ether, which can solve the problem of Reaction control accuracy requirements are high, double bond retention rate decreases, molecular weight distribution broadens, etc., to achieve the effect of narrow relative molecular weight distribution, high double bond retention rate, and improved application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of ethylene glycol monovinyl polyoxyethylene (46) ether:

[0034] Catalyst preparation: Add 1.135mol (100g) ethylene glycol monovinyl ether to a 100ml round-bottom single-necked flask, put it on an electromagnetic stirrer with a water bath and slowly add 0.0908mol (2.65g) lithium tetrahydrogen, and the reaction temperature is 25 °C, reacted for 2.5 hours, and prepared a catalyst after the reaction was complete.

[0035] Add 1.135mol (100g) ethylene glycol monovinyl ether and the above-mentioned catalyst into a 10L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. The air in the kettle was replaced with nitrogen for 3 times, and when the temperature of the kettle rose to 80-85°C, 68.1mol (3000g) of ethylene oxide was passed through for 3.5 hours, and the reaction was continued for 1 hour. Then add 3.03g of sodium hydride, stir and raise the temperature to 100-120°C, and then feed 158.9mol (7000g) of ethylene oxide fo...

Embodiment 2

[0037] The preparation of ethylene glycol monovinyl polyoxyethylene (53) ether:

[0038] Catalyst preparation: Add 1.135mol (100g) ethylene glycol monovinyl ether to a 100ml round-bottom single-necked flask, put it on an electromagnetic stirrer with a water bath and slowly add 0.1135mol (4.31g) lithium tetrahydrogen, and the reaction temperature is 20 °C, react for 3 hours, and prepare the catalyst after the reaction is complete.

[0039] Add 1.135mol (100g) ethylene glycol monovinyl ether and the above-mentioned catalyst into a 10L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. Replace the air in the kettle with nitrogen for 3 times, and when the temperature of the kettle rises to 80-85° C., 90.8 mol (4000 g) of ethylene oxide is passed through for 3.5 hours, and the reaction is continued for 0.5 hours. Then add 6.05g of sodium hydride, stir to raise the temperature to 100-120°C, and feed 181.6mol (8000g) of ethylene oxide for 8 hours...

Embodiment 3

[0041] The preparation of ethylene glycol monovinyl polyoxyethylene (55) ether:

[0042] Catalyst preparation: Add 50 (100 g) ethylene glycol monovinyl ether into a 100 ml round-bottomed single-necked flask, put it into an electromagnetic stirrer with a water bath and slowly add 0.102 mol (3.87 g) lithium aluminum tetrahydride, and the reaction temperature is 15°C , reacted for 4h, and the catalyst was prepared after the reaction was complete.

[0043] Add 1.135mol (100g) ethylene glycol monovinyl ether and the above-mentioned catalyst into a 10L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. Replace the air in the kettle with nitrogen for 3 times, and when the temperature of the kettle rises to 80-85° C., 56.75 mol (2500 g) of ethylene oxide is passed through for 4 hours, and the reaction is continued for 0.5 hours. Then add 0.91 sodium hydride and 0.91 sodium, stir and raise the temperature to 100-120°C, and feed 147.55 mol (6500 g) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com