Curve cleaning machine

A cleaning machine and water washing technology, which is applied in the direction of dryers, cleaning flexible objects, cleaning methods and utensils, can solve the problems of affecting the working environment of workers, and the noise of the air-drying section of the curved washing machine, etc., to reduce labor intensity and wind. The effect of stabilizing and improving the working environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

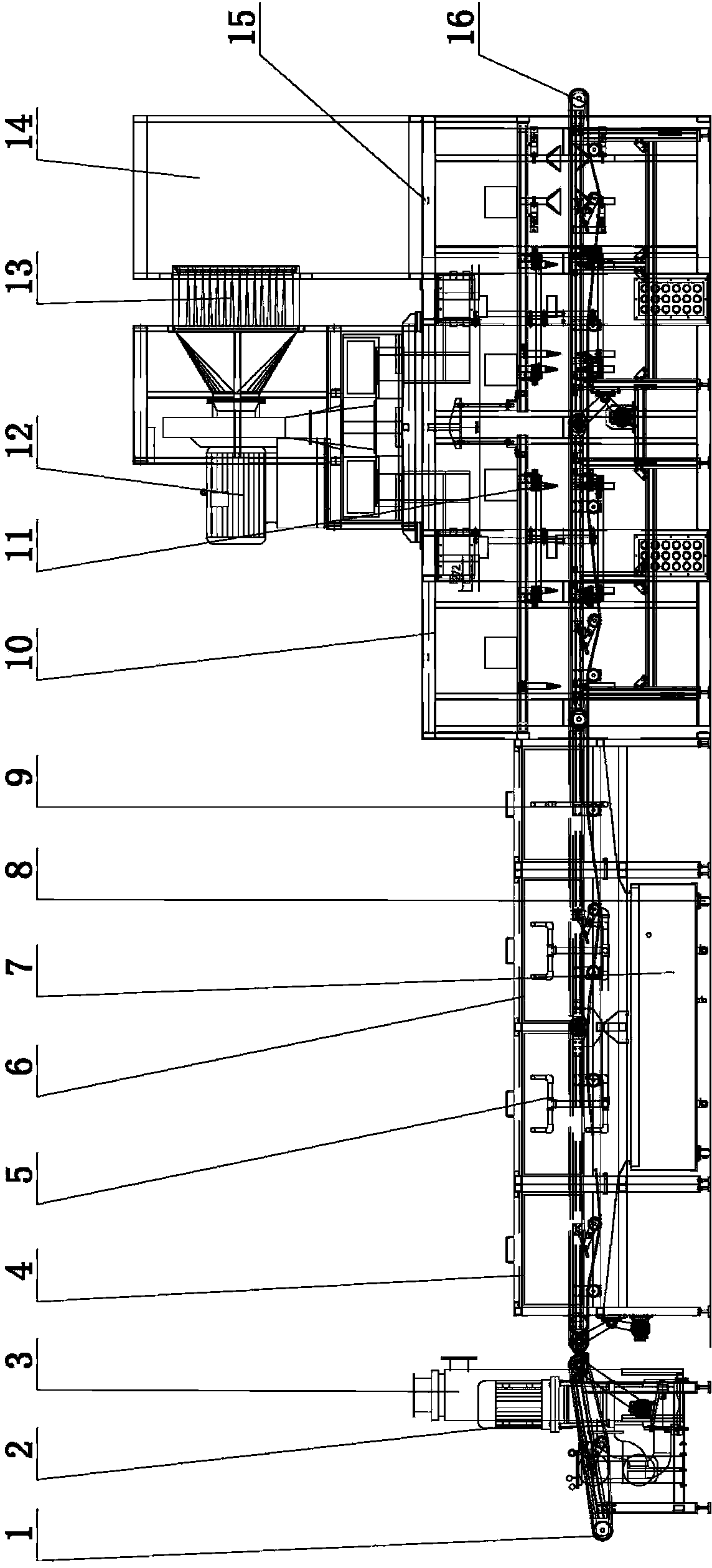

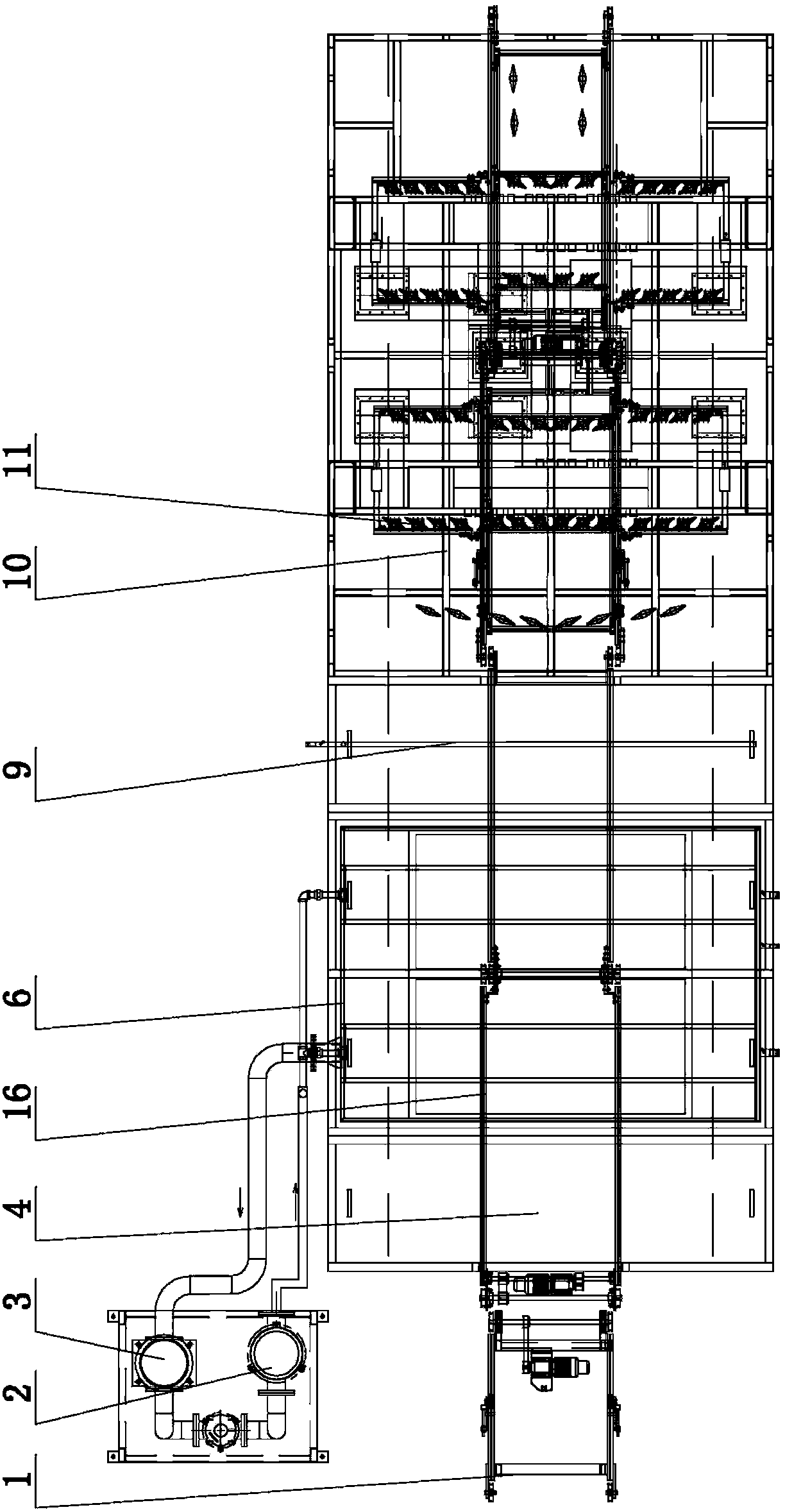

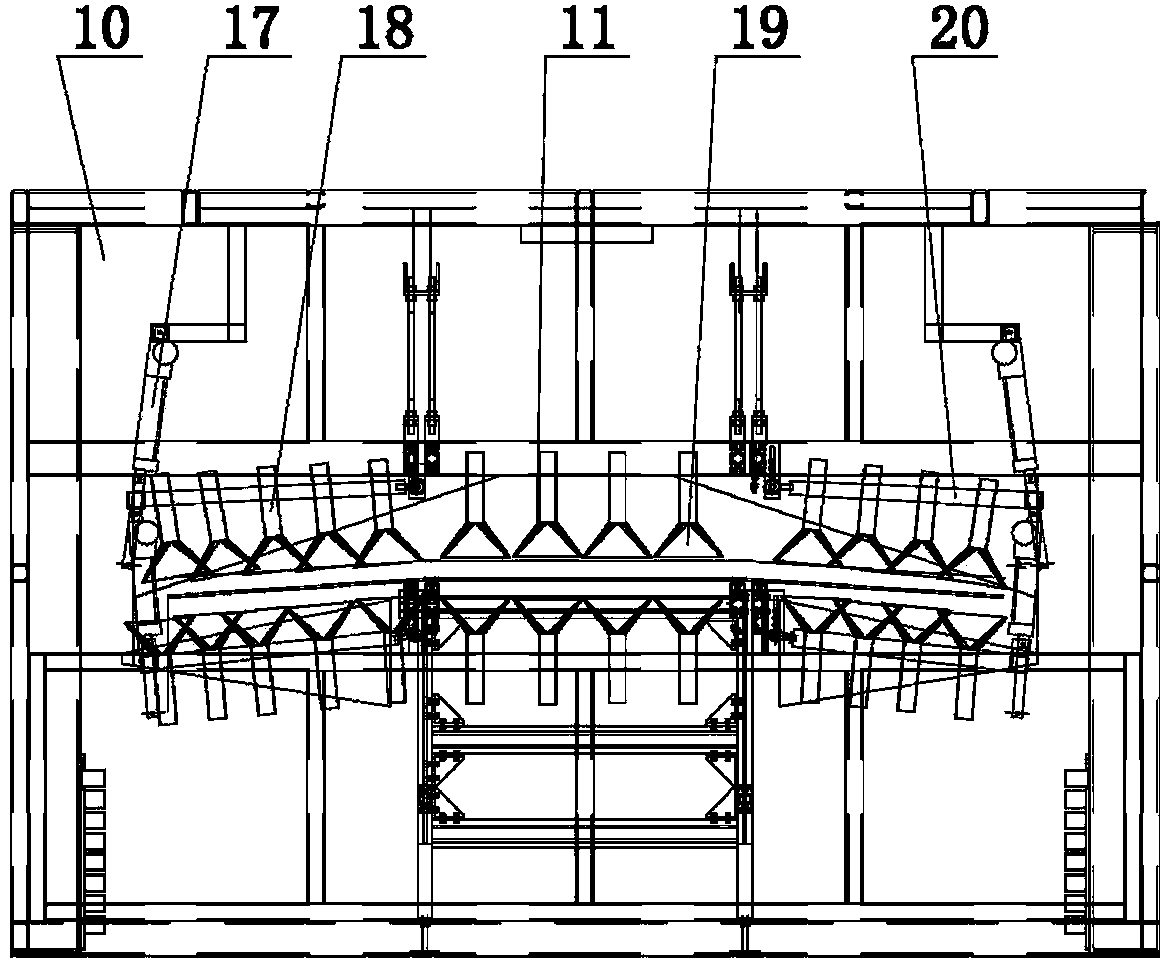

[0020] The present invention includes a washing section 6 and an air-drying section 10. A transmission device 16 is arranged in the washing section 6 and the air-drying section 10. The water-washing section 6 is provided with at least two sets of high-pressure sprays corresponding to the top and bottom of the transmission device 16. Corresponding to the high-pressure spray pipe 5, a water tank 7 is arranged below the pipe 5 and the water washing section 6, and the feature is that the water tank 7 is connected to at least two groups of high-pressure spray pipes 5 through the circulating water pump 2 and the heater 3 .

[0021] The bottom of the water tank 7 is provided with a traveling wheel 8; the traveling wheel 8 facilitates the movement of the water tank 7 and facilitates maintenance of the present invention.

[0022] A sheet loading conveyor 1 is arranged in front of the washing section 6 , and a buffer section 4 is arranged between the washing section 6 and the sheet loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com