Integrated molding mould of dead head and casting cavity

A technology for molding molds and casting molds, which is applied to casting molding equipment, casting mold components, casting molds, etc., can solve problems that affect the quality of casting products, time-consuming and labor-consuming, riser damage, etc., to save time for loose sand cleaning, The effect of improving production efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

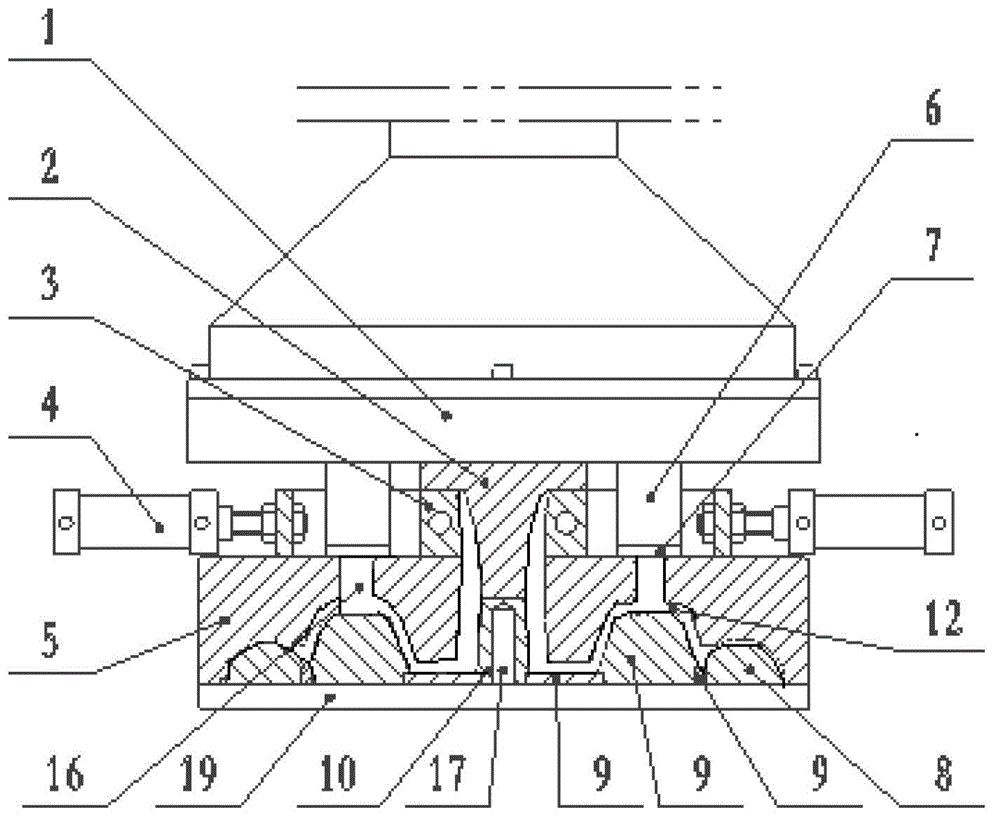

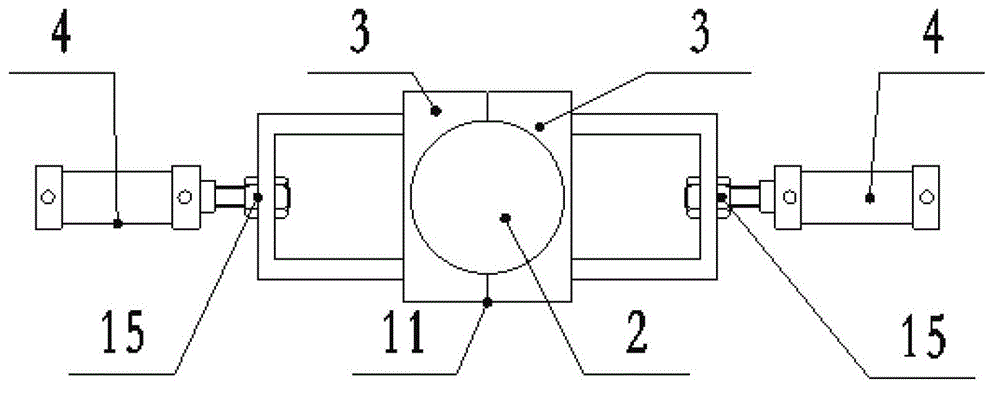

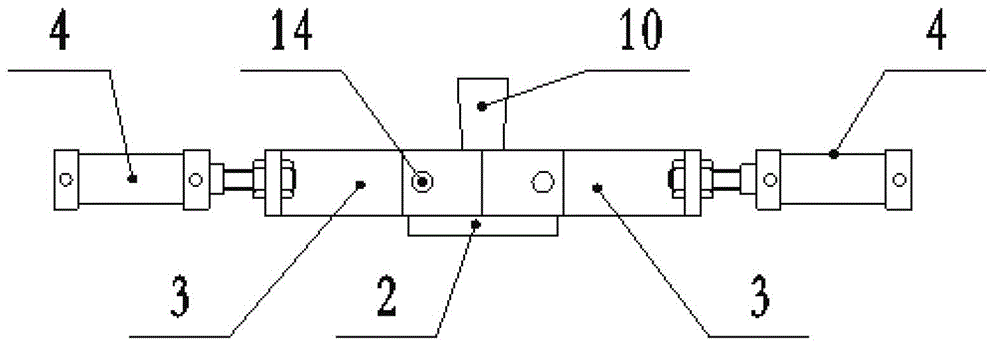

[0032] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

[0033] Such as figure 1 As shown, the riser and the casting cavity are integrally formed into a mold, including a core shooting machine, a casting mold upper mold 5 and a casting mold upper mold 5 combined box molding template 19, the molding template 19 has a casting product model 8 and a casting molding template Pouring system model 9; the nozzle 6 of the core shooting machine is connected with the sand shot hole 16 of the upper mold 5 of the casting mold; it also includes a riser forming mold 3 arranged on the upper mold 5 of the casting mold, and the riser forming mold 3 is provided with Molding hole, the upper mold 5 is provided with a mold hole communicating with the molding hole, the mold hole is a through hole, and the mold hole penetrates from the upper end surface of the upper castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com