Cushion block for bench drilling machine

A cushion block and mattress technology, which is applied to the parts of the boring machine/drilling machine, drilling/drilling equipment, clamping, etc., can solve the problems that affect the flatness of the surface of the cushion block, the machining accuracy of the workpiece, and the unevenness of the surface of the cushion block. Achieve the effect of simple structure, guaranteed flatness and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

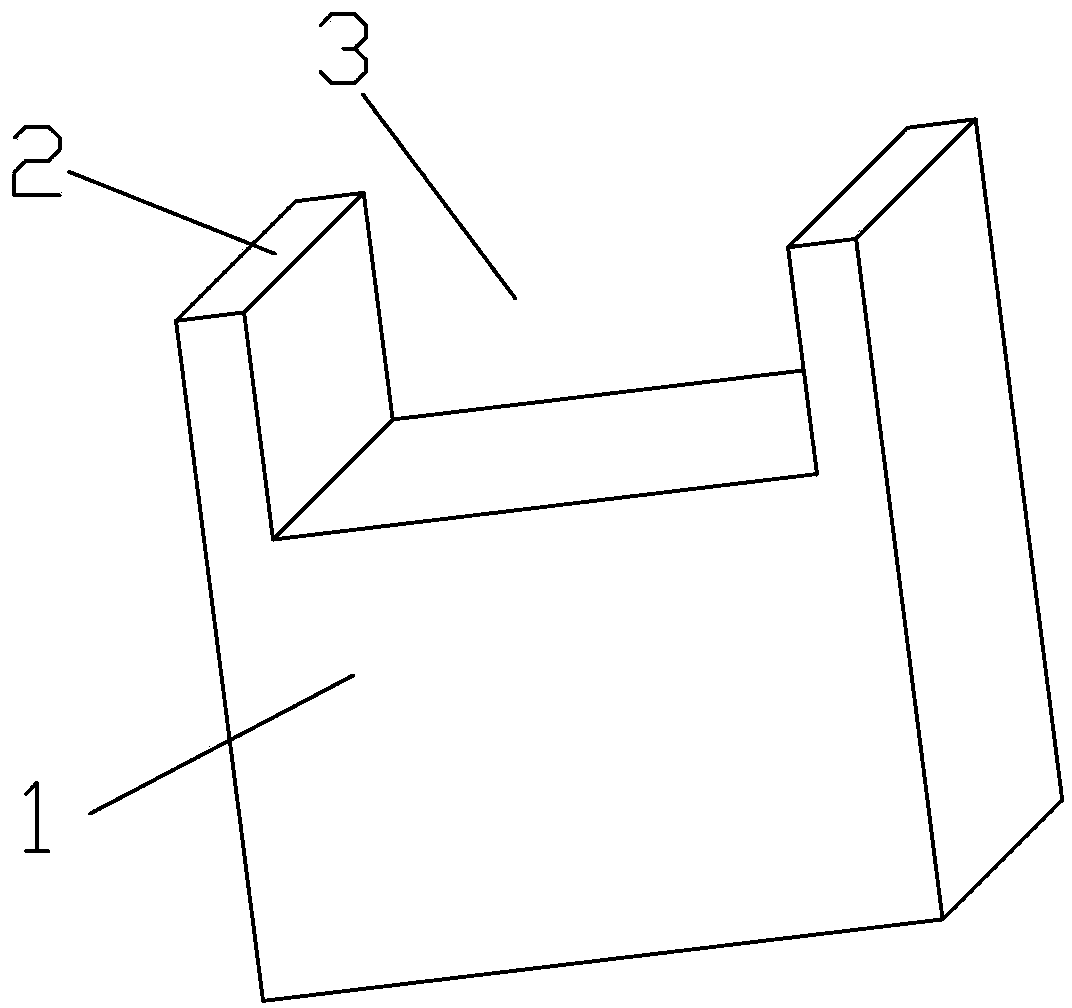

[0013] like figure 1 Shown, a kind of bench type drilling machine block, it comprises block body 1, and upper plane middle part of block body 1 is made with upper through groove 3, and the two sides of upper through groove 3 form upper leg 2, and the upper leg 2 The upper plane is parallel to the lower plane of the spacer body 1 .

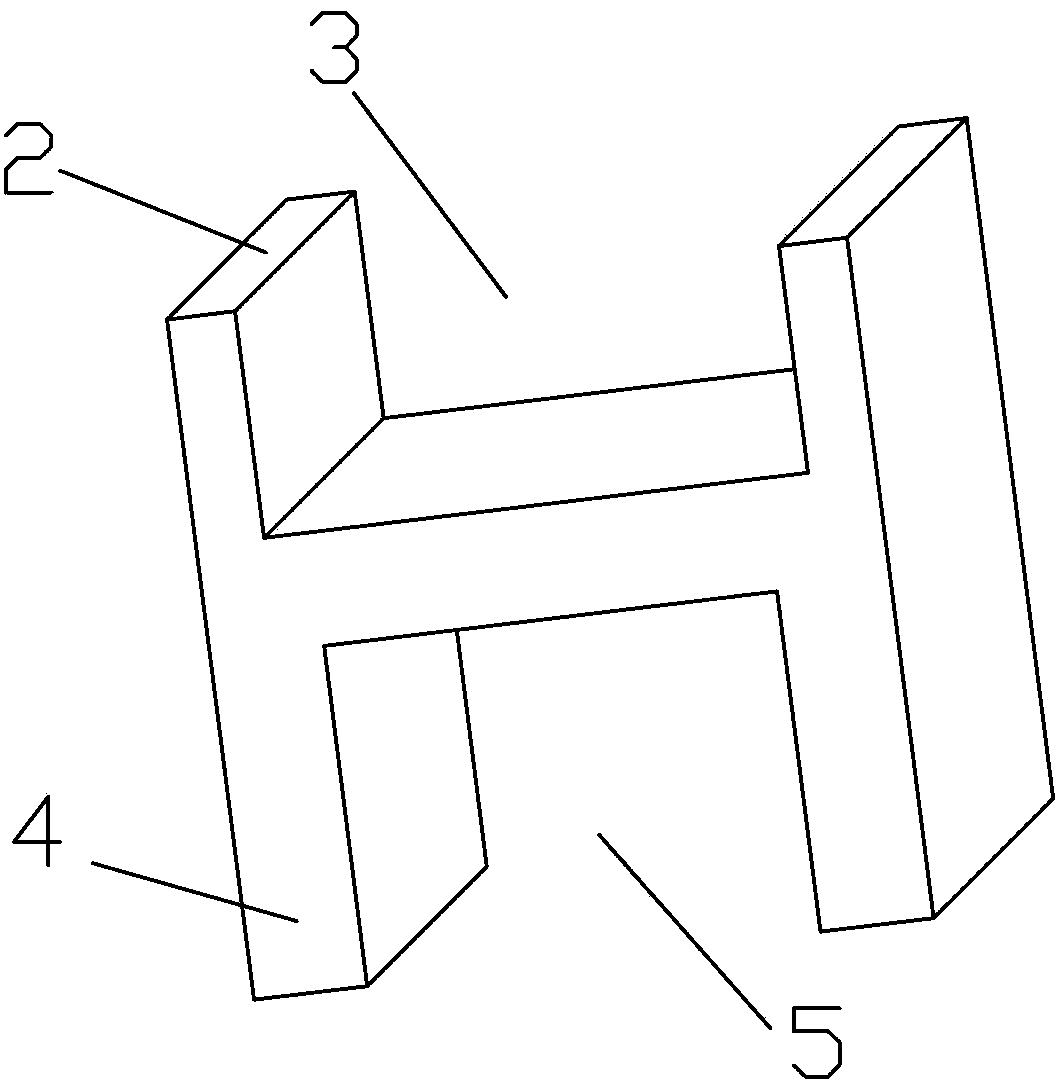

[0014] like figure 2 As shown, in the middle part of the lower plane of the pad body 1, a lower through groove 5 is formed, and the lower legs 4 are formed on both sides of the lower through groove 5, and the pad body 1 forms an "H" shape. The lower plane of the leg 4 is parallel to the upper plane of the upper leg 2 .

[0015] The depth of the lower through groove 5 is greater than the depth of the upper through groove 3 .

[0016] When processing the through hole of the workpiece on a desktop drilling machine, put the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap