Squeeze double-roll distance adjusting device

A technology for adjusting device and roller spacing, which is applied in the direction of presses, presses using rotating pressure components, manufacturing tools, etc. It can solve problems such as affecting product quality, avoid human factors, improve extrusion effects, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

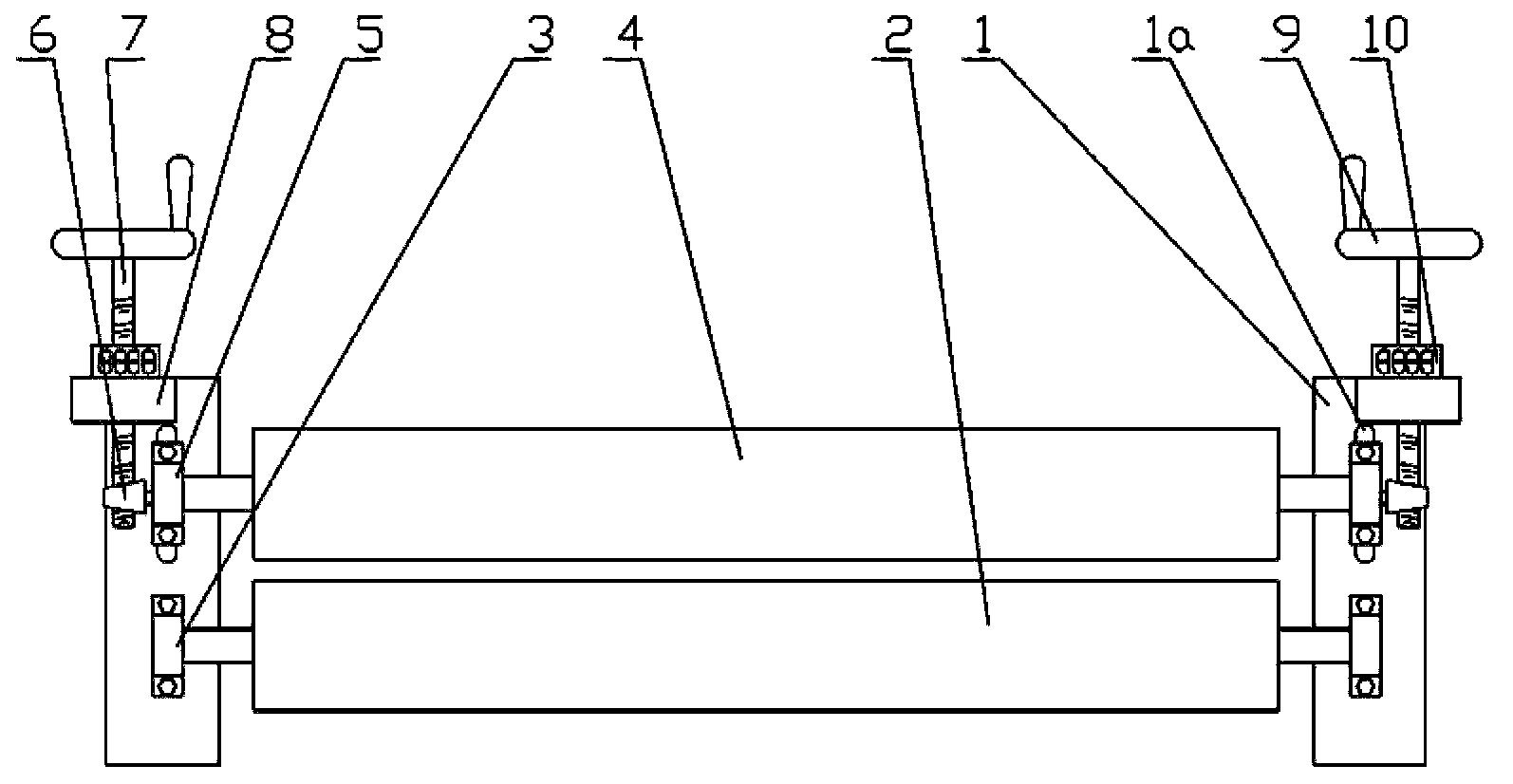

[0011] Example: see figure 1 As shown, the extrusion roller spacing adjustment device includes a roller support 1, the roller shaft of the fixed roller 2 is installed on the fixed roller bearing seat 3, and the fixed roller bearing seat 3 is fixed on the roller support 1 by bolts;

[0012] The roller shaft of the movable roller 4 is installed on the movable roller holder 5, and the movable roller holder 5 is fixed on the waist-shaped hole 1a of the roller bracket 1 by bolts; the movable roller holder 5 is fixed with a worm wheel 6, and the worm 7 is screwed On the adjustment seat 8, the worm screw 7 is fixed on the handle 9.

[0013] A digital display 10 is installed on the worm 7 , and the housing of the digital display 10 is fixed on the adjustment seat 8 .

[0014] Working principle: Loosen the bolts on the movable roller holder 5, adjust the position of the movable roller holder 5 by shaking the worm 7, and then tighten the bolts, so that the distance between the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com