Station arrangement structure of idling motor automatic final inspecting and labeling integrated machine

An idle motor and automatic technology, applied to typewriters, conveyor objects, printing, etc., can solve the problems of low work efficiency, loss of manufacturers and consumers, and high labor costs, and achieve the effect of improving work efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

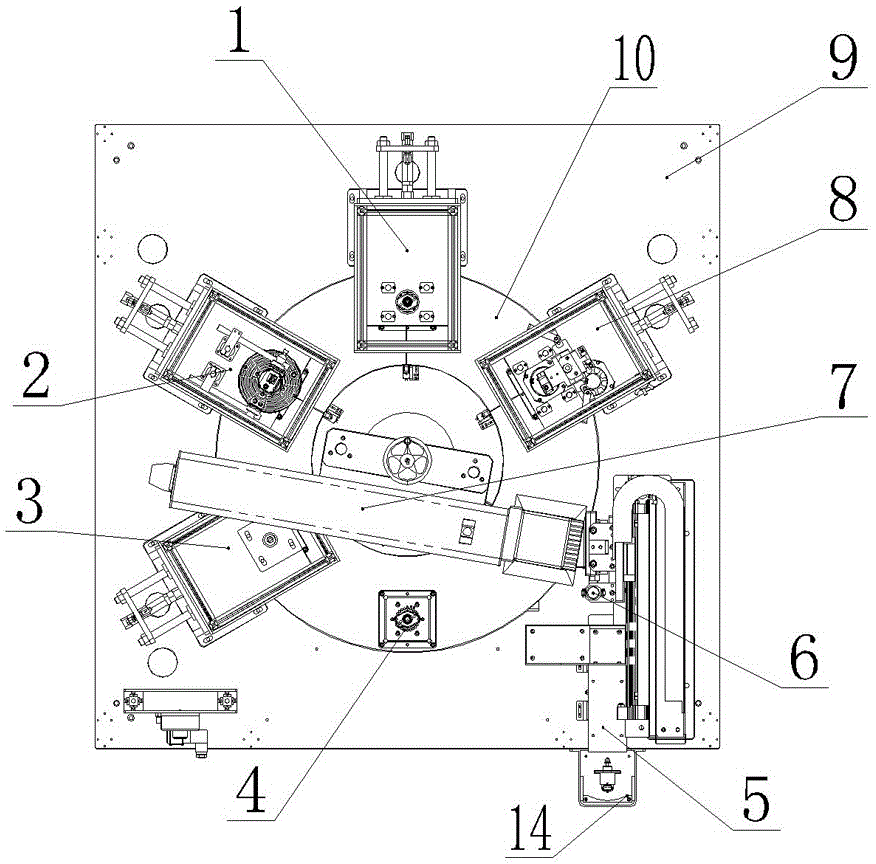

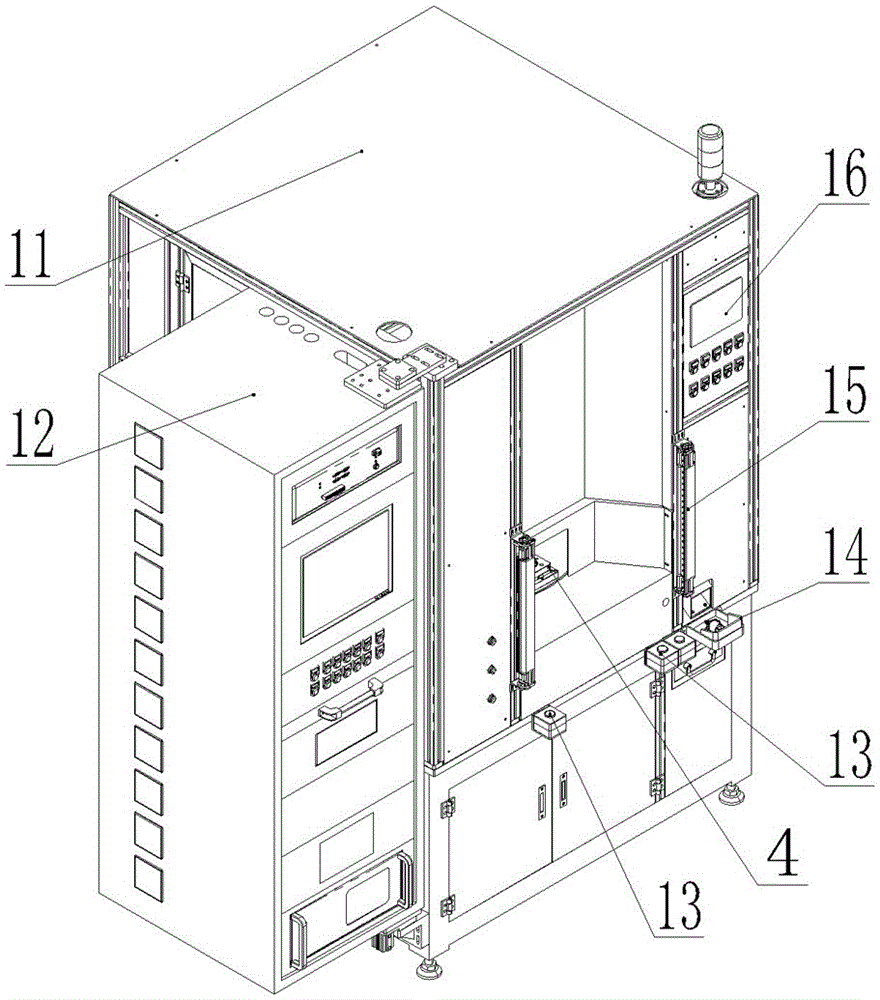

[0010] Such as figure 1 with figure 2 Shown: an idle motor automatic final inspection and marking integrated machine station arrangement structure, including turntable 10, air tightness detection device 3, concentricity detection device 2, resistance detection device 1, thrust and lost step detection device 8, Marking device 7, blanking device 6, turntable 10 is set on bottom plate 9, turntable 10 is provided with a number of product clamps 4, in this embodiment air tightness detection device 3, concentricity detection device 2, resistance detection device 1. Thrust and lost step detection device 8, marking device 7 and blanking device 6 are arranged on the bottom plate 9 around the turntable 10 and corresponding to the position of the product clamp 4, and a blanking slide 5 is provided behind the blanking device 6.

[0011] Among them, a material box 14 is connected after the material chute 5.

[0012] Among them, the outer periphery of the bottom plate 9 is provided with a safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com