Rotary tea leaf withering and shaking device

A shaking device and rotary technology, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of heating, uneven friction, unstable tea quality, low tea processing efficiency, etc., and improve the stability. and its quality, avoid human adverse factors, improve quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0019] Example.

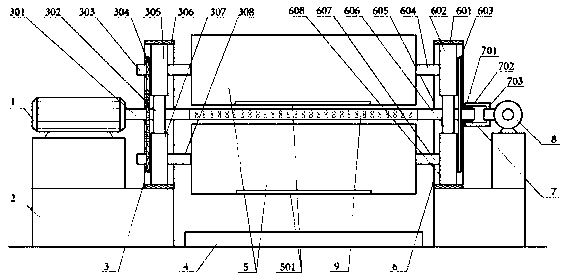

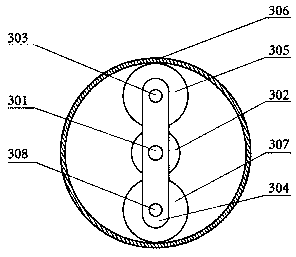

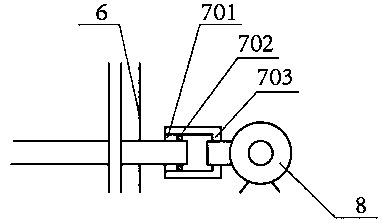

[0020] A rotary tea withering and shaking device, comprising a machine base 2, a main planetary wheel 3 and a secondary planetary wheel 6 are arranged above the machine base 2, the main planetary wheel 3 is connected to a motor 1, and the motor 1 is connected to the machine The motor 1 drives the main planetary gear 3 to rotate; the main planetary gear 3 and the sun gear shaft of the auxiliary planetary gear 6 are connected with a ventilation pipe 9, which drives the ventilation pipe 9 to rotate around the axis of the sun gear shaft. The direction is the same as the rotation direction of the sun gear; the mesh cylinder 5 is connected between the planetary gear shafts of the main planetary gear 3 and the auxiliary planetary gear 6, and the main planetary gear 3 drives the mesh cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com