Interior anti-abnormal slide rail mechanism

A slide rail and abnormal sound technology, applied in the field of auto parts, can solve the problems of reducing the effective restraint of parts, affecting the sliding performance, and setting a large friction resistance of the cushion pad, so as to improve comfort, reduce friction and eliminate abnormal sound Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

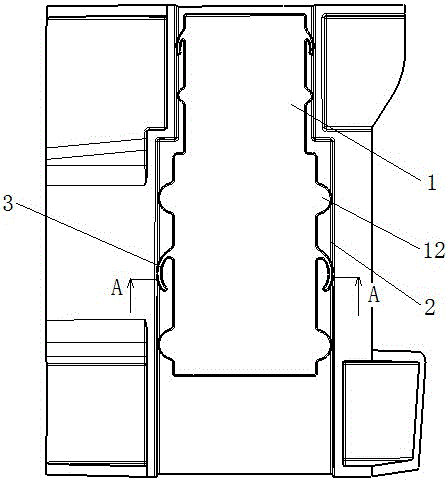

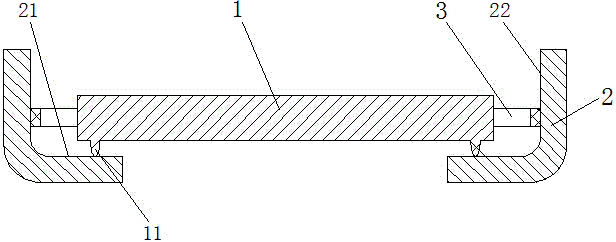

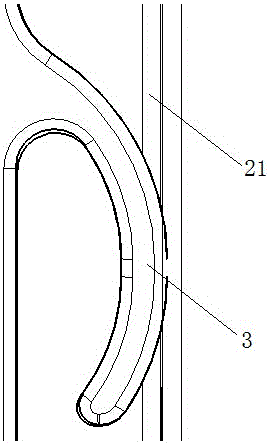

[0018] Such as figure 1 , 2 As shown in , 3, an interior decoration anti-squeaky slide mechanism is composed of two parts: a slide part 1 and a slide rail 2. The slide rail 2 is provided with a protruding support surface 21, and the two sides of the slide part 1 The bottom surface of the bottom surface is erected on the support surface 21, and the slide plate part 1 and the slide rail 2 cooperate to form a moving pair. The slide plate part 1 is also provided with an elastic part 3, and the bottom of the elastic part 3 is fixedly installed on the side of the slide plate part 1. , the top of the elastic member 3 abuts against the side wall 22 of the slide rail 2 .

[0019] In the present invention, in order to ensure that the connection between the elastic member 3 and the slider 1 has a certain structural strength, so that the elastic member 3 can really function without being damaged by the impact force, the elastic member 3 is formed by the slider 1 The sides of the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com