Automated tidying system

A power mechanism and panel technology, applied in the field of finishing systems, can solve problems such as low efficiency, laborious, time-consuming, etc., and achieve high efficiency, smooth connection, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments

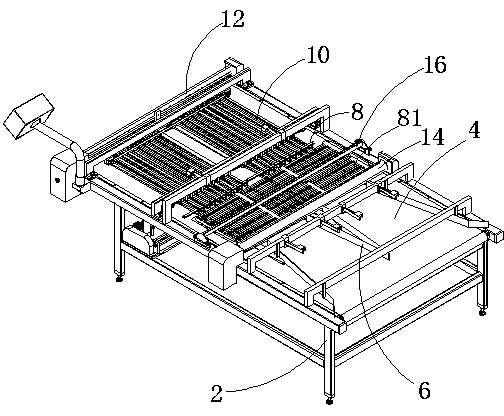

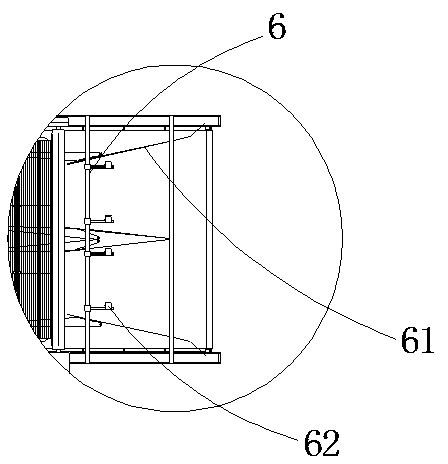

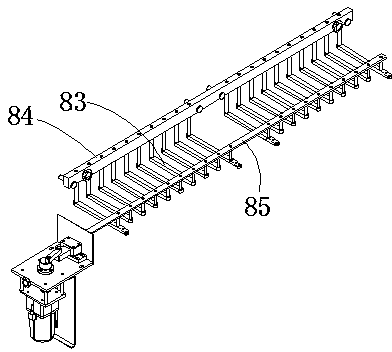

[0023] See figure 1 Said, an automated sorting system of the present invention includes a bracket 2, a horizontal conveying panel 4 is provided on the bracket 2, and a grouping mechanism 6 for grouping products is provided at the beginning of the panel 4. The mechanism 6 is connected to the trough-entry power mechanism 8, and the trough-entry power mechanism 8 is connected to the product guide trough 10. The end of the product guide trough 10 is provided with a feeding mechanism 12, in addition, above the grouping mechanism 6 A steering roller 14 that can be automatically rotated under the drive of a driving device is provided. The steering roller 14 is at a height from the surface of the panel 4 to enable the product to lie flat on the surface of the panel 4, and a pressing material is provided between the steering roller 14 and the product guide groove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap