Automatic hanging three-dimensional storage sorting delivery system

A conveying system and hanging technology, which is applied in the hanging-type three-dimensional warehouse multi-task automatic parallel picking and conveying system and in the field of picking and conveying, can solve the problems that it is difficult to realize multi-task parallel picking of clothing, shoes and bags, and achieve less rental cost sharing, The effect of high selection efficiency and high efficiency of sorting and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

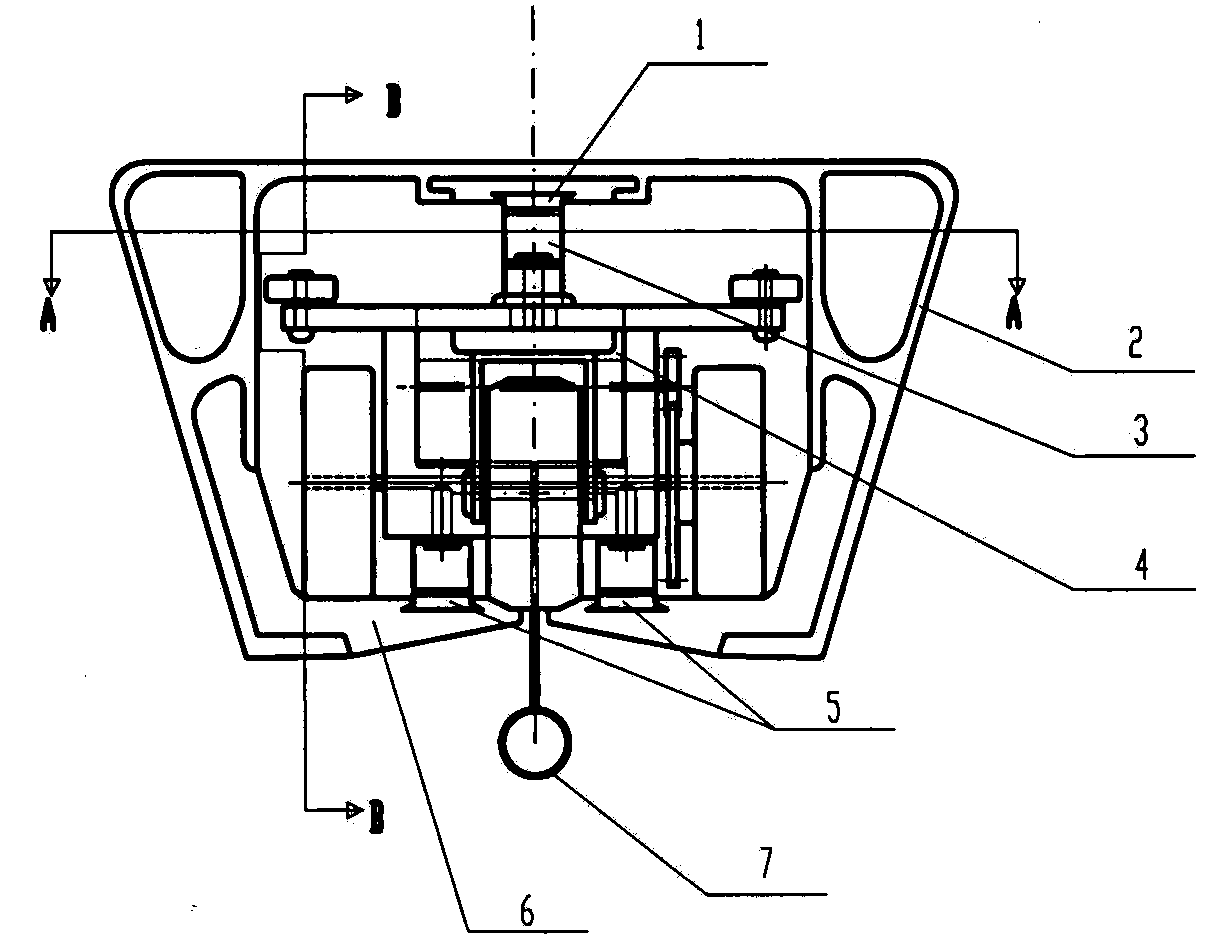

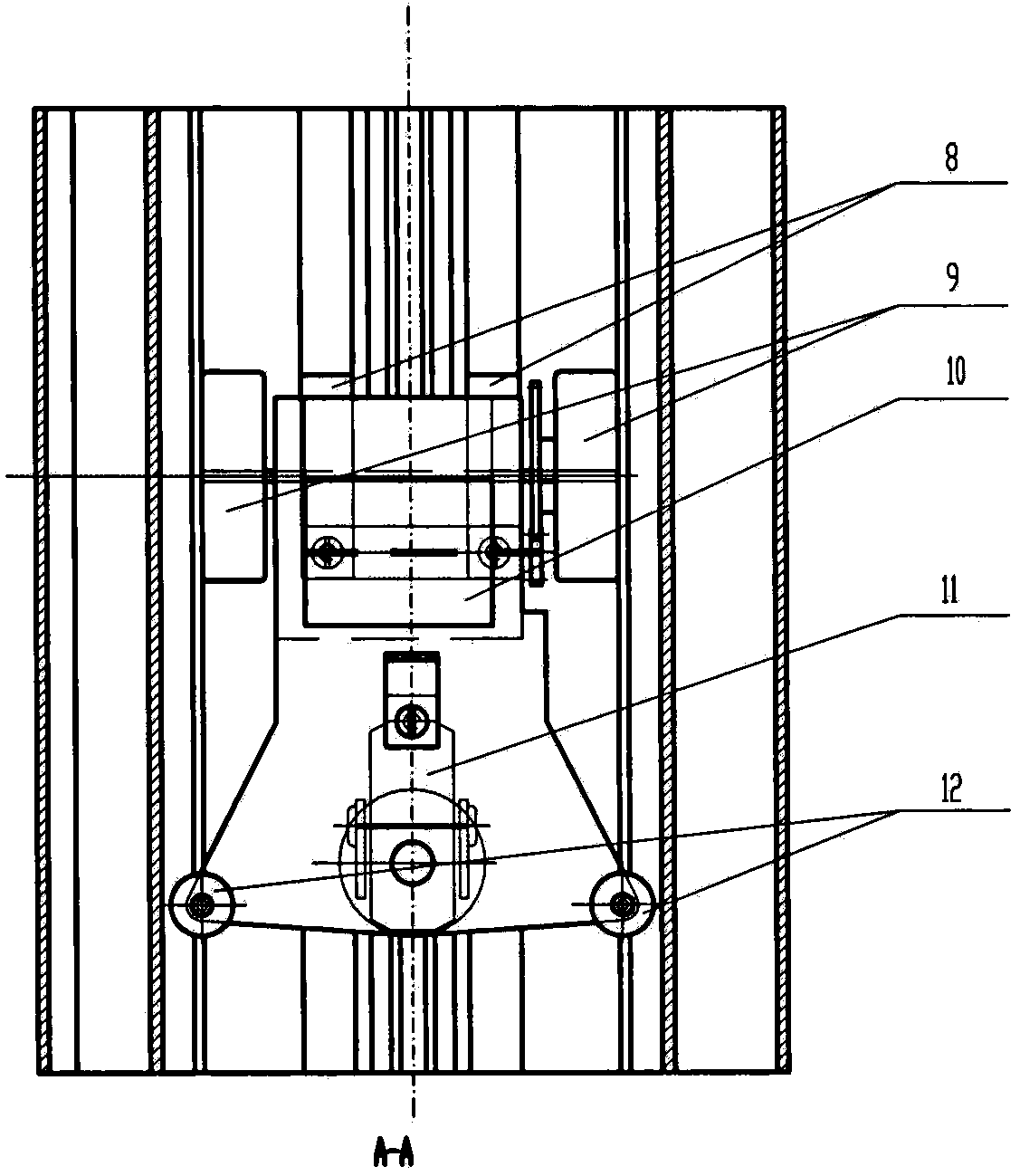

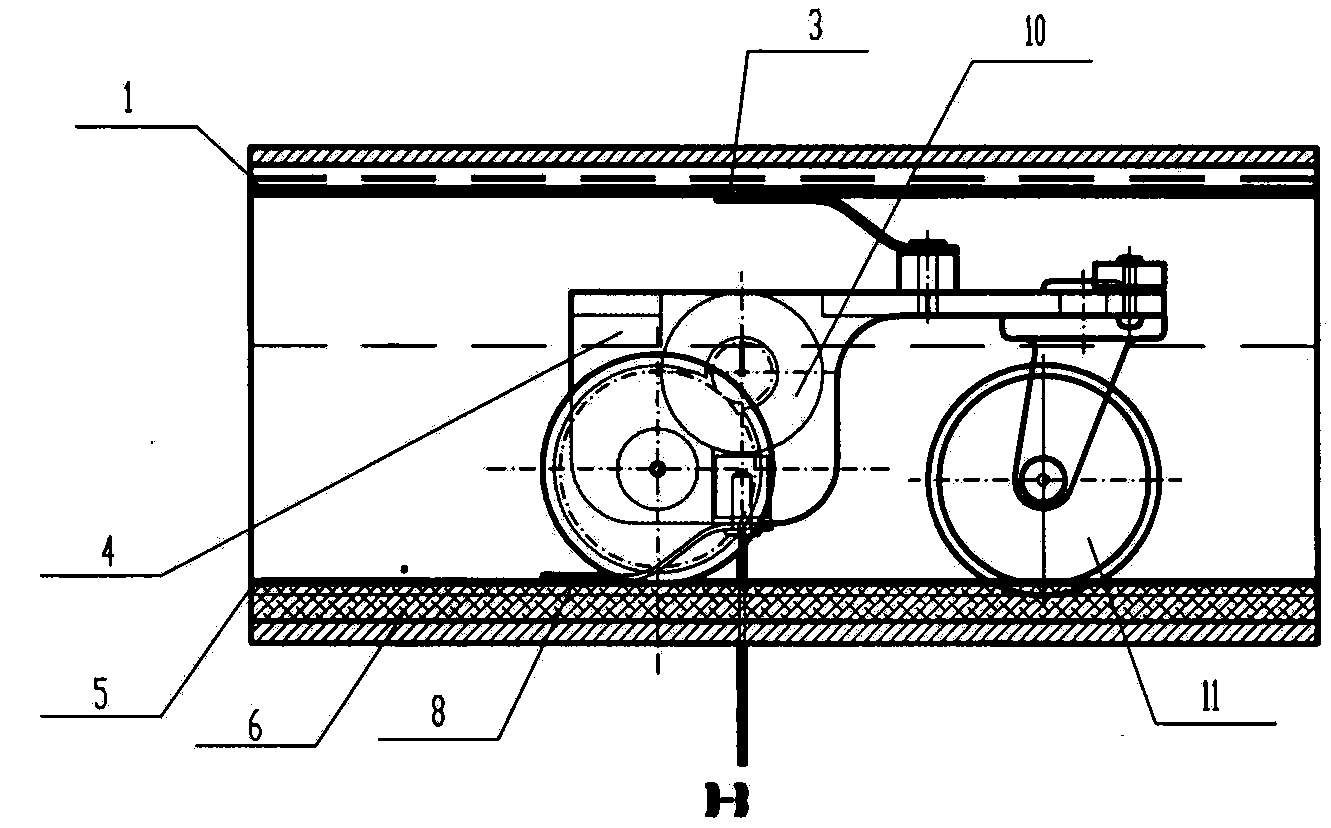

[0039] A hanging type three-dimensional storage automatic picking and conveying system, including PLC, WMS, Ω-shaped hanging rails embedded with internal wires, and a bridge mechanism composed of a stacking channel 13, a stacking channel 14, and multi-layer three-dimensional shelves, through which a remote control car passes. The wires in the Ω-shaped suspension track are powered and driven. According to the WMS command received by the communication module on the remote control trolley, the PLC controls the trolley to start and stop in the Ω-shaped suspension track, and deliver the products hung on the rings of the remote control trolley to the designated WMS. s position. The area designated by WMS includes the temporary storage space of the three-dimensional shelf and various experience areas. WMS (Warehouse Managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com