Self-adjusting thread tensioning device for winding yarns

A technology of tensioning device and winding machine, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as tension cannot be adjusted and problems in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

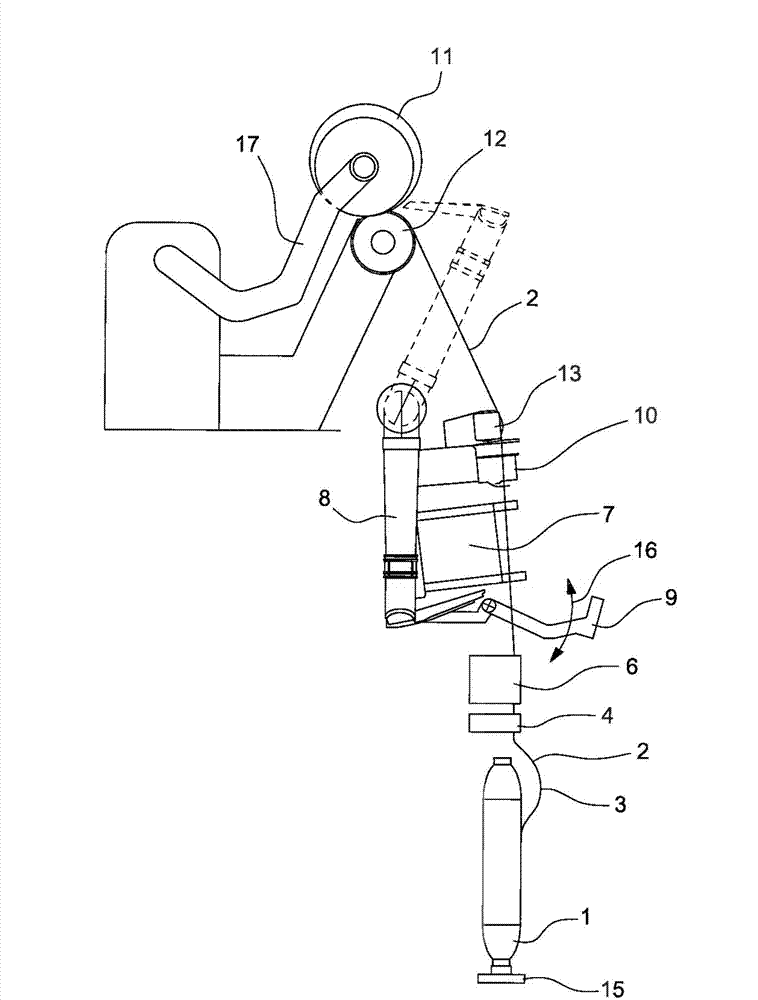

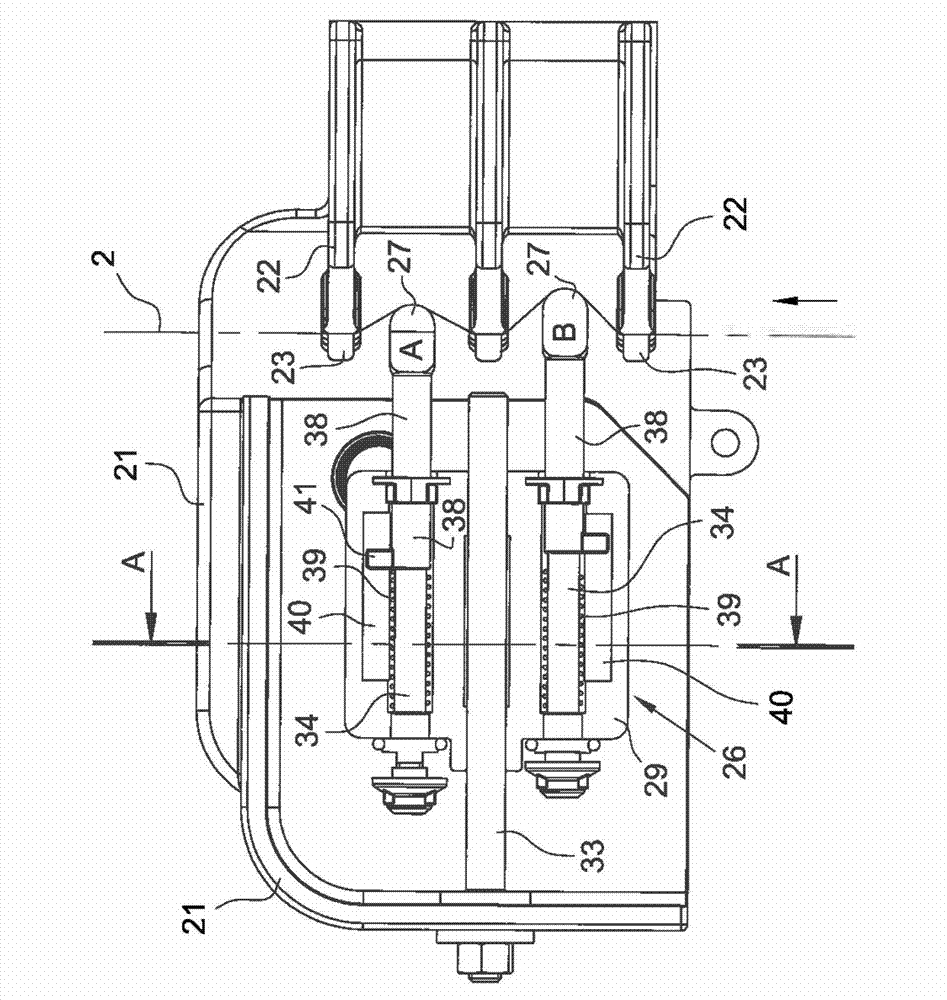

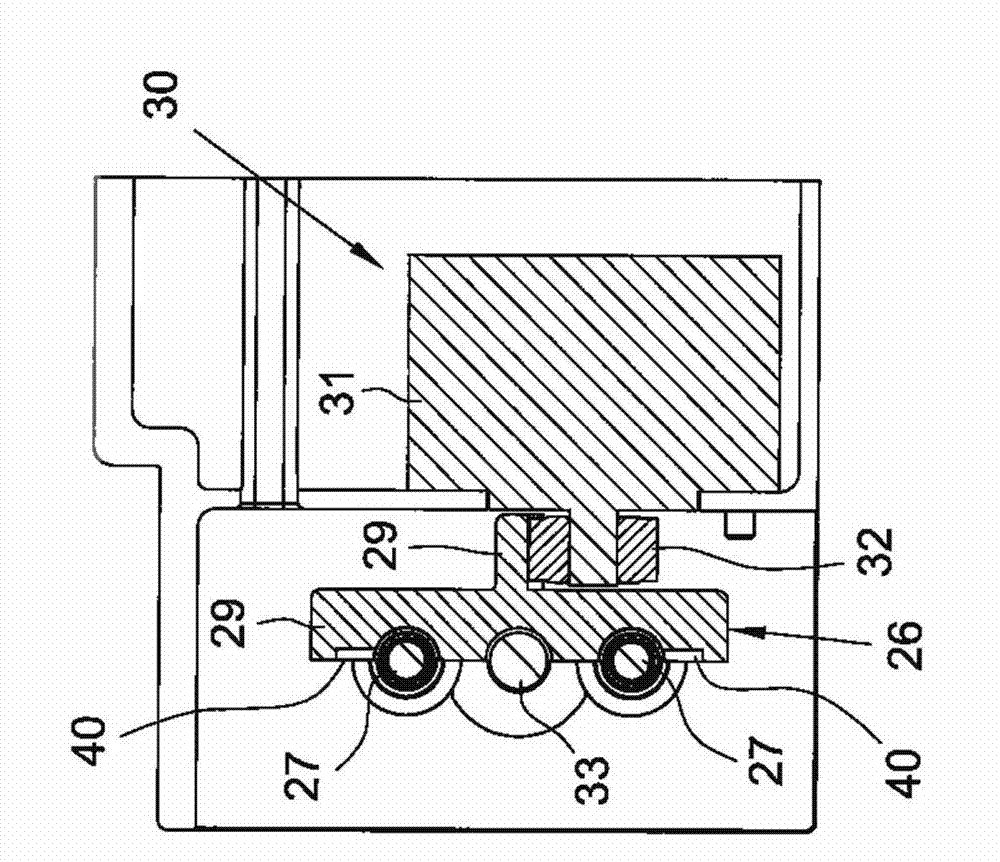

[0029] by pair Figures 1 to 4 The features and advantages of the line tensioning device according to the invention will become clearer from the description of typical embodiments of the invention shown in the description, which are given as examples and not for purposes of limitation.

[0030] figure 1 A side view of a spool unit is schematically shown and shows a technical problem. Figure 2A -C shows the solution of the wire tensioning device according to the invention inserted in the winding station. Figure 2A shows the front view of the device, while Figure 2B A section according to A-A is shown. Figure 2C An isometric view of the device is shown in more detail.

[0031] Alternatively, the idea according to the technical solution of the present invention can be based on image 3 The scheme of the structure shown in is made, according to image 3 The scheme of the structure shown in is identical to the scheme according to FIG. 2 .

[0032] Figure 4 is an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com