A self-venting waterproof membrane and preparation method thereof

A waterproof membrane, self-adhesive technology, applied in chemical instruments and methods, water conservancy projects, other chemical processes, etc., can solve the problems of membrane rupture, water loss, increase project cost, etc., to restore anti-seepage performance, easy construction, Strong self-healing effect of repairing cracks and micro-holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

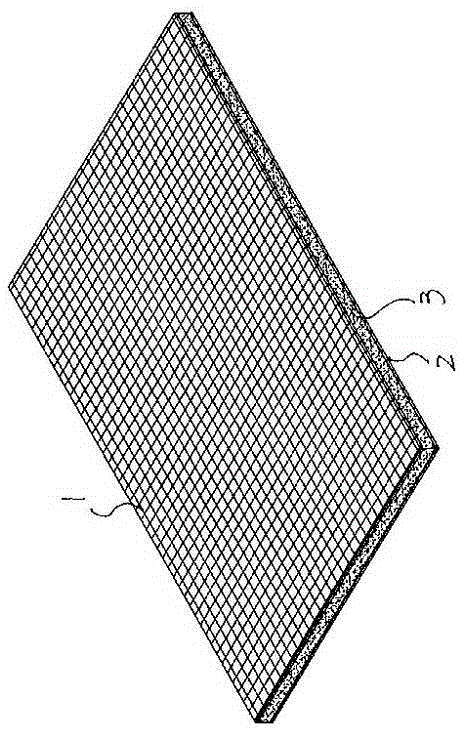

Image

Examples

Embodiment 1

[0028] The first step is to prepare the reinforcement lining

[0029] First, singe the polyester filament non-woven geotextile with a specification of 200 g / m2, and control the elongation to 58% for later use.

[0030] The second step is to prepare water-swellable self-adhesive sheet

[0031] First, take 5 parts by weight of natural rubber, 10 parts by weight of water-soluble polyurethane prepolymer and 80 parts by weight of natural sodium bentonite, 1 part by weight of white wax oil as softener, 1 part by weight of petroleum The resin is used as a thickener, 1 part by weight of porogen functional filler and 0.5 part by weight of anti-aging agent D are sequentially added to the internal mixer, mixed at 140 ° C for 15 minutes, and then filtered by a rubber filter; then, Add the filter gel into the preheated screw extruder to extrude into a water-swellable self-adhesive sheet with a thickness of 3 mm;

[0032] The third step compound

[0033] The water-swellable self-adhesive...

Embodiment 2

[0036] The first step is to prepare the reinforcement lining

[0037] First, the polyester filament non-woven geotextile with a specification of 300g / square meter is singed, and the elongation is controlled to 50%, and it is set aside.

[0038] The second step is to prepare water-swellable self-adhesive sheet

[0039] First, get 10 parts by weight of butyl rubber, 5 parts by weight of water-soluble polyurethane prepolymer and 70 parts by weight of calcium-based bentonite, 1.5 parts by weight of pine tar as softener, 1.5 parts by weight of rosin Make a thickener, 1.5 parts by weight of porogen functional filler and 2.0 parts by weight of anti-aging agent 4010A, sequentially add to the internal mixer, mix at 110 ° C for 25 minutes and filter the rubber with a rubber filter; then, put The filter gel is added to the preheated screw extruder and extruded into a water-swellable self-adhesive sheet with a thickness of 3.5 mm;

[0040] The third step compound

[0041] The water-swe...

Embodiment 3

[0044] The first step is to prepare the reinforcement lining

[0045] First, the polyester filament non-woven geotextile with a specification of 350 g / m2 is singed, and the elongation is controlled to 45%, and it is set aside.

[0046] The second step is to prepare water-swellable self-adhesive sheet

[0047] First, take 8 parts by weight of nitrile rubber that has been masticated, 20 parts by weight of sodium acrylate polymer water-absorbing resin and 30 parts by weight of sodium bentonite, 0.5 parts by weight of naphthenic oil as a softener, 1.5 parts by weight of Rosin is used as a thickener, 1.5 parts by weight of porogen functional filler and 1.5 parts by weight of anti-aging agent D are sequentially added to the internal mixer, mixed at 130°C for 20 minutes, and then filtered by a rubber filter; then, Add the filter glue to a preheated screw extruder to extrude into a water-swellable self-adhesive sheet with a thickness of 4.0 mm;

[0048] The third step compound

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrostatic pressure | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap