Method for improving memory cutting execution precision of coal mining machine

A coal shearer and memory technology, which is applied in the field of improving the execution accuracy of the memory cutting of the coal shearer, can solve the problems of low coincidence degree, large amount of remaining coal, difficult control of memory cutting execution accuracy, etc., so as to improve the smoothness and improve the The effect of execution precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

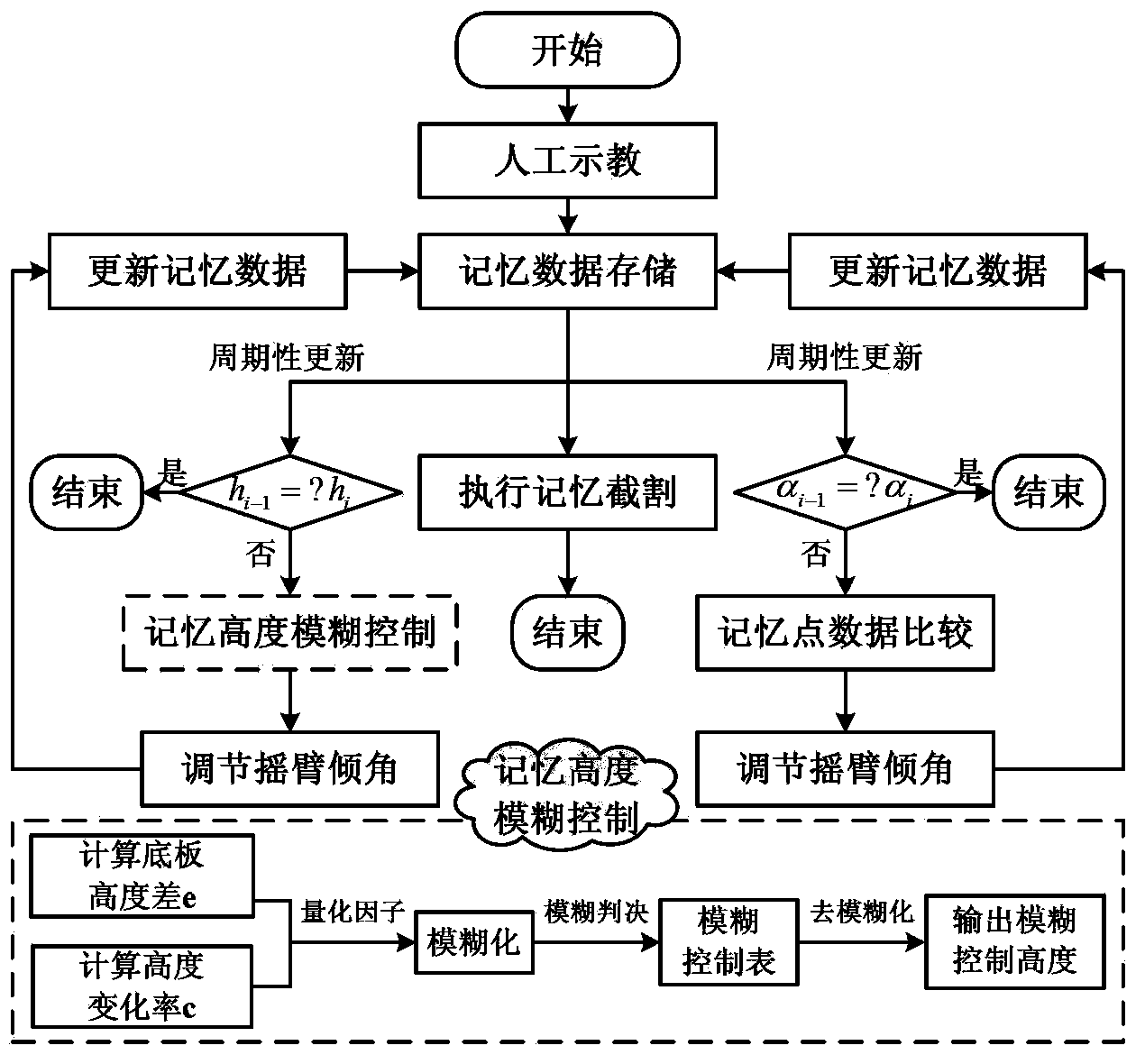

[0032] The present invention will be further described below in conjunction with accompanying drawing.

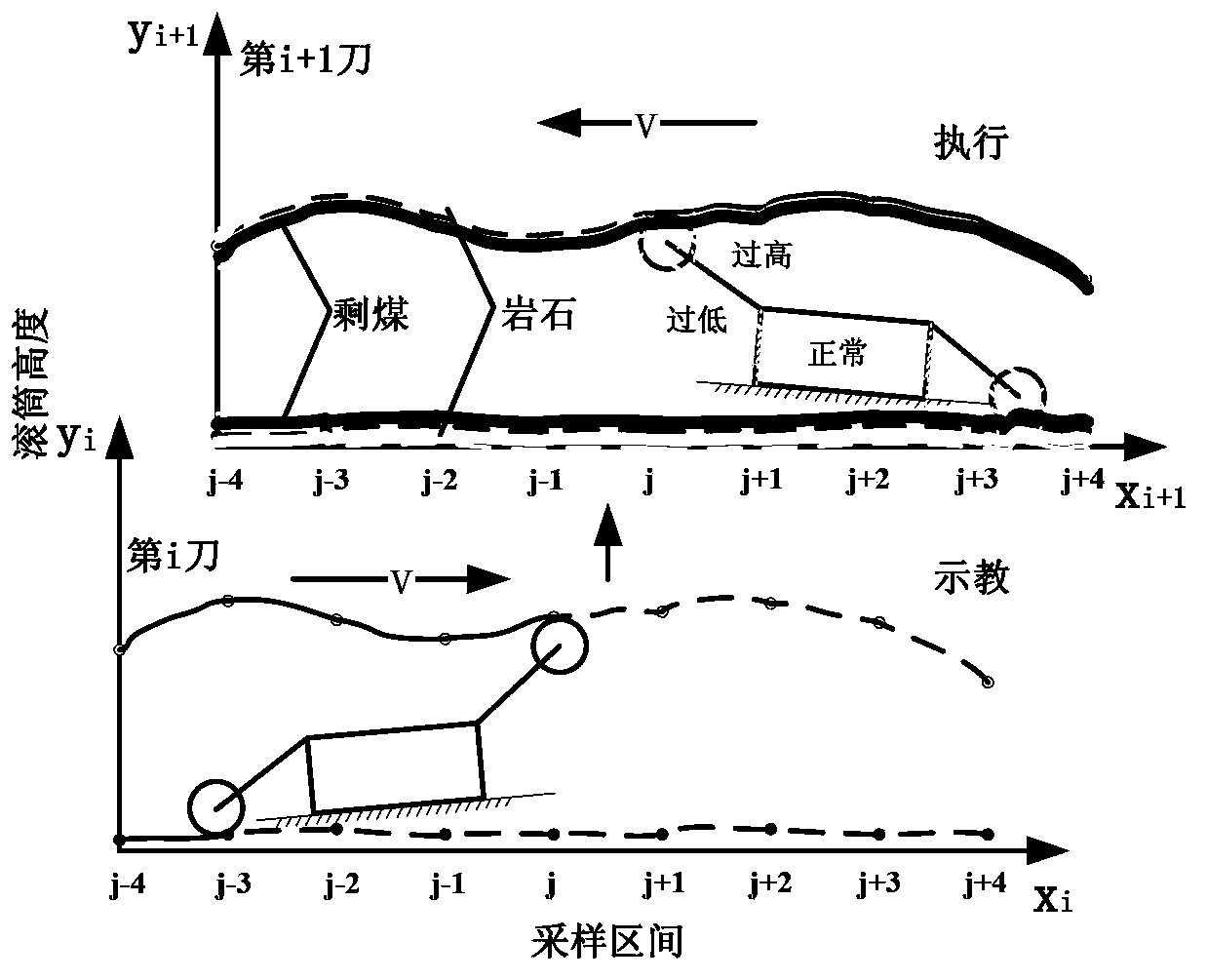

[0033] Such as image 3 As shown, the specific steps of the method for improving the execution accuracy of shearer memory cutting are:

[0034] (1) Data collection: collect the floor height of each cutter of the shearer and the inclination angle of the rocker arm of the shearer, and calculate the height difference e between the front and rear cutter floors, the rate of change in height deviation c, and the change in inclination angle of the rocker arm of the shearer Δβ 2 ;

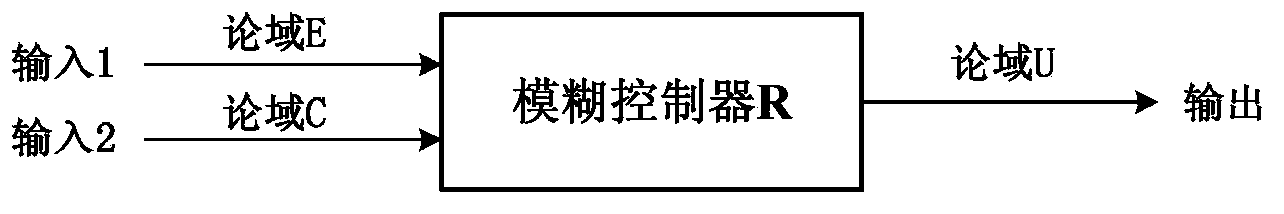

[0035] (2) Determine the input and output variables: For the memory cutting execution accuracy decrease caused by the height change of the floor, consider the height difference e between the front and rear blades and the height deviation change rate c as fuzzy input; change the inclination angle of the shearer rocker arm Δβ 2 As a fuzzy output, the fuzzy controller adopts a two-dimensional input-sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com