Automobile drum type brake heat dissipation system

A heat dissipation system, drum-type technology, applied in the direction of brake type, brake parts, mechanical equipment, etc., can solve the problems of reducing vehicle carrying capacity, icy road traffic accidents, increasing the extra load of the car, etc., to ensure stable and normal performance Operation, reduce transportation costs, improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

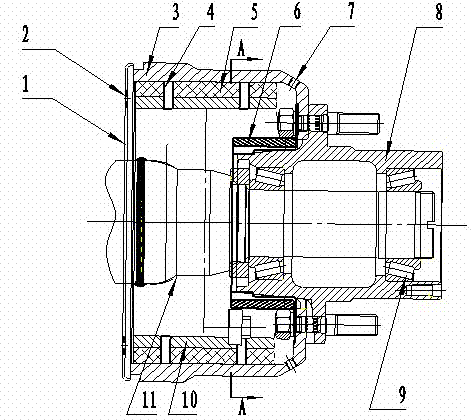

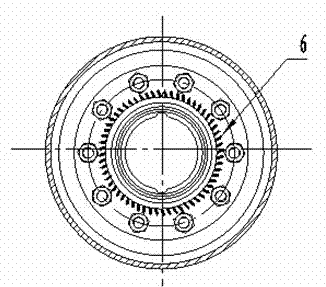

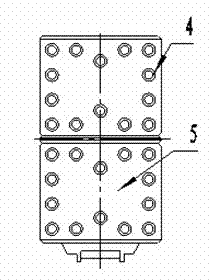

[0017] It includes an axle 11, the axle is installed with the hub 8 through the bearing 9, the inner side of the hub is connected with the brake drum 3 through the flange plate with the connecting bolt, the inner cavity of the brake drum is equipped with a brake shoe, and the brake shoe includes The brake shoe 10 and the friction plate 5, the friction plate and the brake shoe are riveted together through the rivet 4 with a through hole, so that the heat generated between the brake shoe and the brake drum can be dissipated in time, and the heat dissipation effect is further enhanced Install a wind wheel or fan blade 6 near the bottom of the brake drum inner cavity, the wind wheel or fan blade is connected with the brake drum through the connecting bolts of the brake drum and the hub, and runs synchronously with the hub brake drum; Air intake holes 7 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com