A double heat source vertical dryer and a drying system using the dryer

A vertical dryer and dual heat source technology, applied in the direction of dryers, drying, heating devices, etc., can solve the problems of reducing the flow rate of materials and limiting the drying efficiency of vertical dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

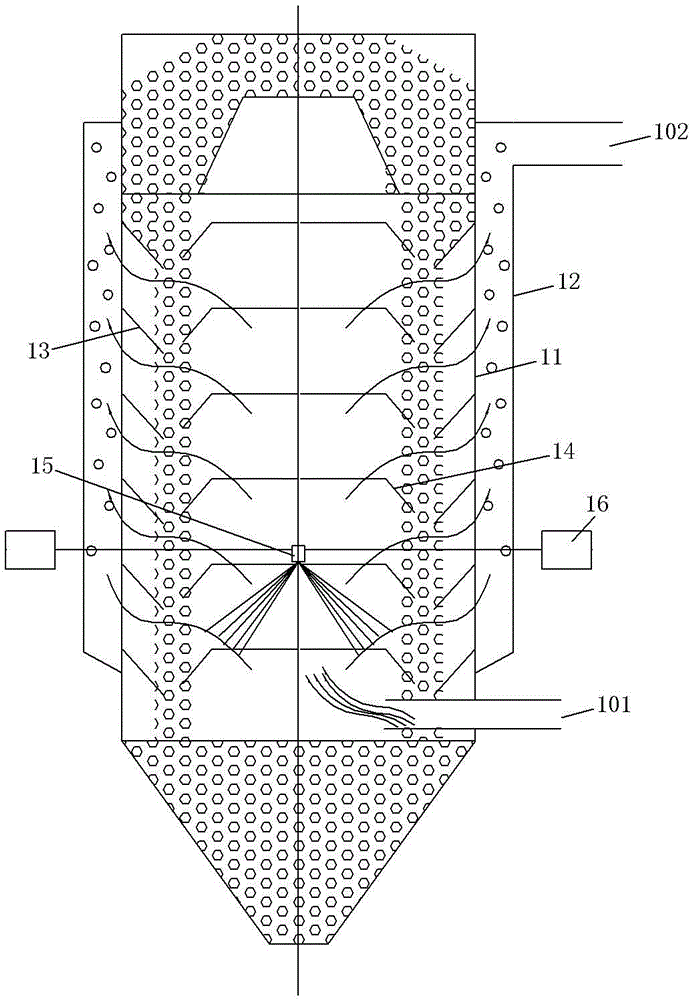

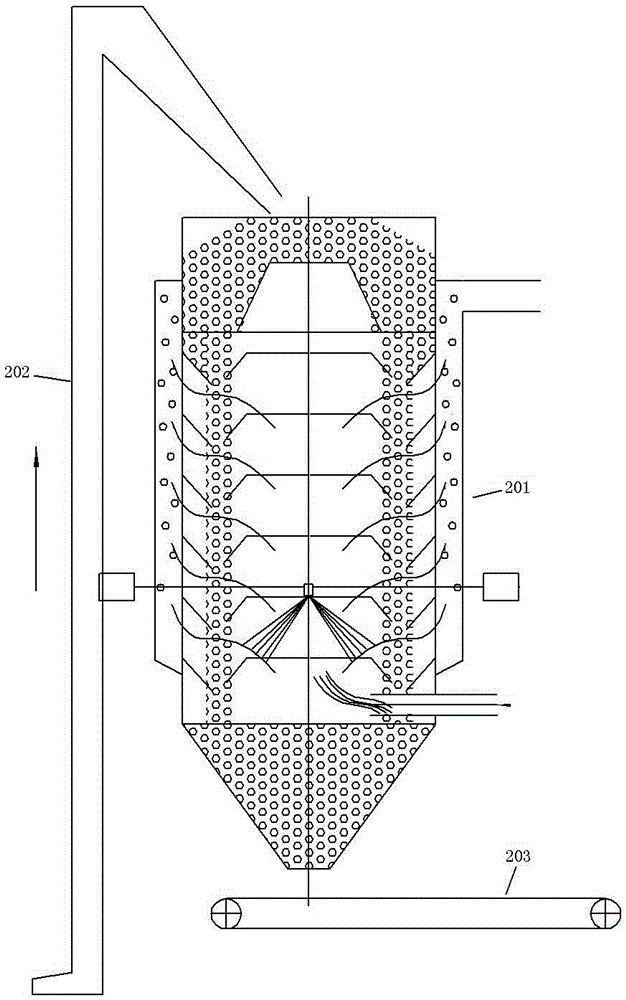

[0017] Examples of dual heat source vertical dryers, such as figure 1 As shown, including the furnace body, the top of the furnace body is provided with a feed inlet, the bottom is provided with a hot air inlet 101, and the bottom is provided with a discharge port. In this embodiment, the furnace body is a jacketed structure, which includes an inner layer The inner tank 11 and the outer shell 12, the inner tank 11 is provided with internal and external air holes, its inner side is provided with a lifting plate 13, the outer shell is provided with an exhaust port 102, and the exhaust port 102 is used to communicate with the corresponding dust collector connection.

[0018] The inner liner 11 of the furnace body is also provided with a retaining ring 14 and a microwave conduit 15, the retaining ring 14 is roughly in the shape of a truncated cone sleeve, and the microwave outlet of the microwave conduit 15 is covered in the retaining ring 14 and is located at the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com