PCB (printed circuit board) spraying and etching production line

A technology of spray etching and production line, which is applied in the field of PCB spray etching production line, can solve the problems of affecting the etching rate, inaccessibility, and inability to flow away in time, so as to improve the production quality and overcome the pool effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

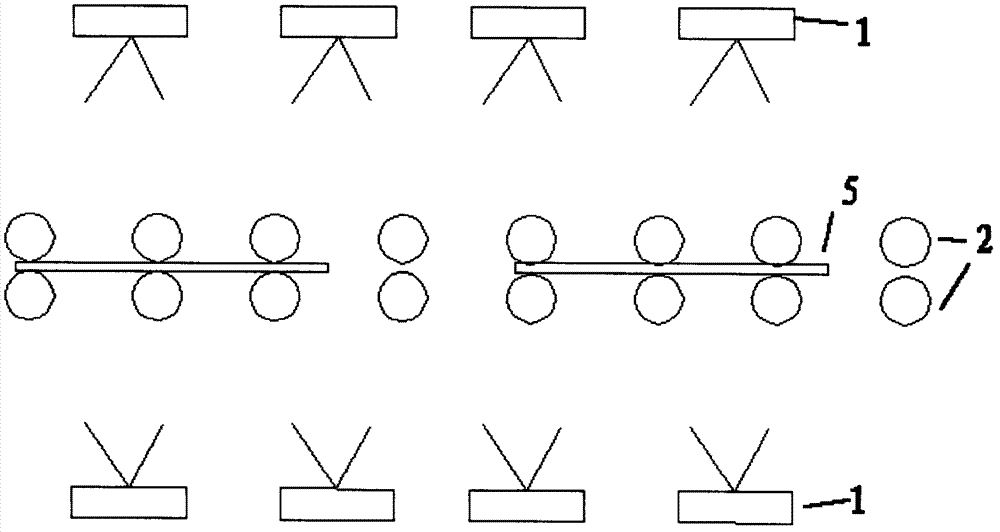

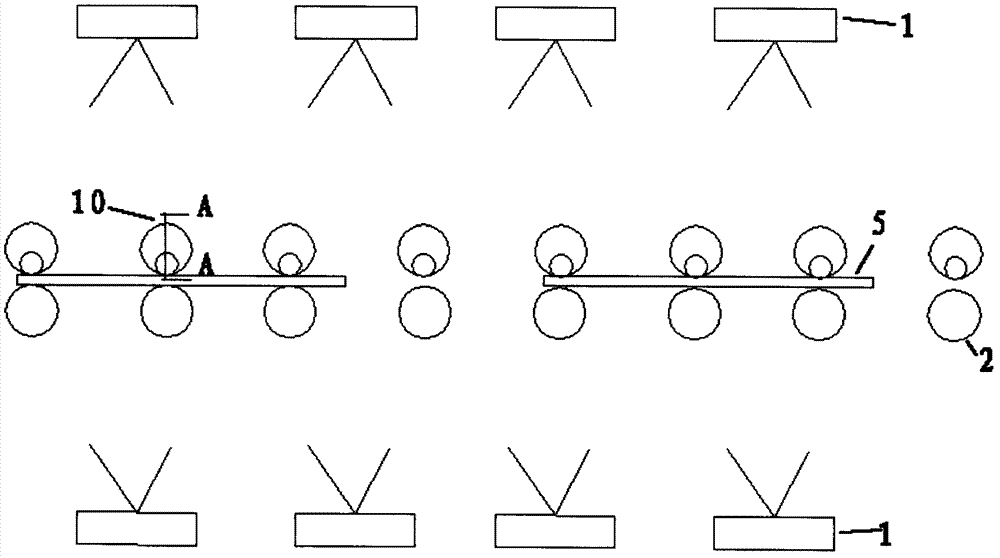

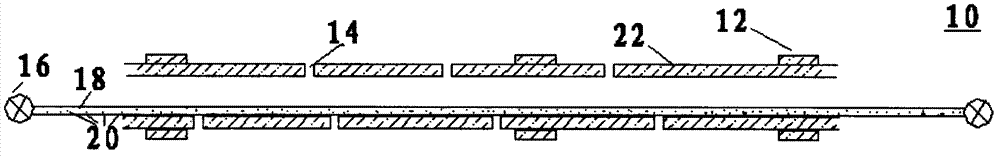

[0013] figure 2 A side view of a PCB spray etching production line according to an embodiment of the present invention is shown, including:

[0014] Upper and lower rows of spray heads 1 opposite to each other are used for spraying etching solution;

[0015] The upper row of rollers 10 and the lower row of rollers 2, the two rows of rollers are opposite to each other, located in the middle of the upper and lower rows of opposite spray heads, and the rollers 2 and 10 are used to clamp and transmit the PCB board 5;

[0016] At least a part of the upper row of rollers 10 has a negative pressure structure for sucking the etching solution on the upper surface of the PCB board 5 .

[0017] Because the PCB spray etching production line uses rollers to suck the waste liquid on the upper surface of the PCB, it avoids the accumulation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com