Wheel rotor

A technology for wheel loaders and work machines, which is applied in the direction of control mechanism, mechanical control device, earth mover/shovel, etc. to achieve the effect of good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below using the drawings.

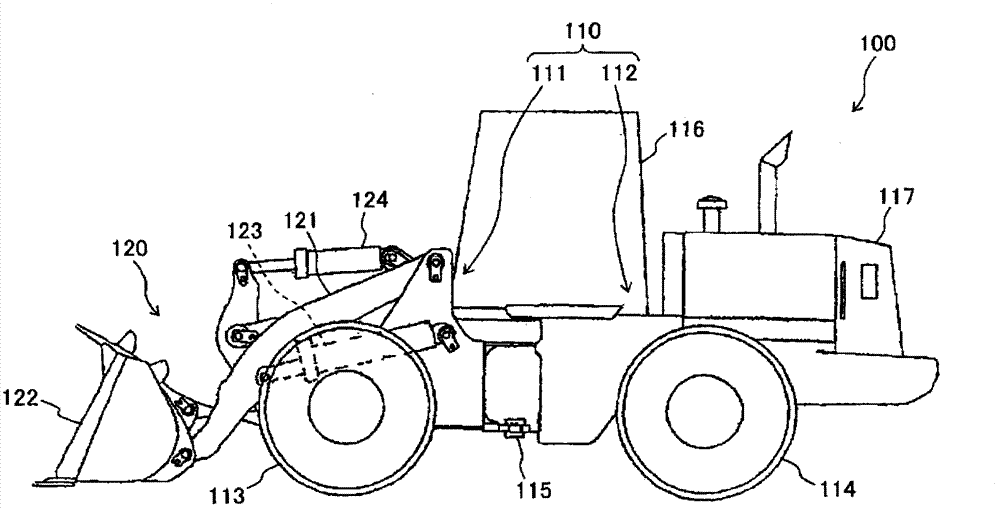

[0027] figure 1 It is a side view of the wheel loader according to one embodiment of the present invention.

[0028] figure 1 The illustrated wheel loader 100 includes a vehicle body 110 and a working machine 120 attached to the front of the vehicle body 110 .

[0029] The vehicle body 110 includes a front body 111 and a rear body 112 . The front body 111 and the rear body 112 have front wheels (tyres) 113 and rear wheels (tyres) 114 respectively, and are connected to each other in a bendable manner via a center pin 115 extending in the vertical direction. Although not shown in the figure, a steering cylinder is connected to the front body 111 and the rear body 112 , and the front body 111 bends left and right with respect to the rear body 112 as the steering cylinder is telescopically driven. In addition, a cab 116 is mounted on the front portion of the rear body 112 , and an engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com