Rotary Cutters for Lawn Mowers

A rotary cutting and lawn mower technology, applied in cutters, harvesters, applications, etc., can solve the problems of removal, inability to cooperate, and deterioration of the weight balance of the head body, so as to avoid the effect of reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

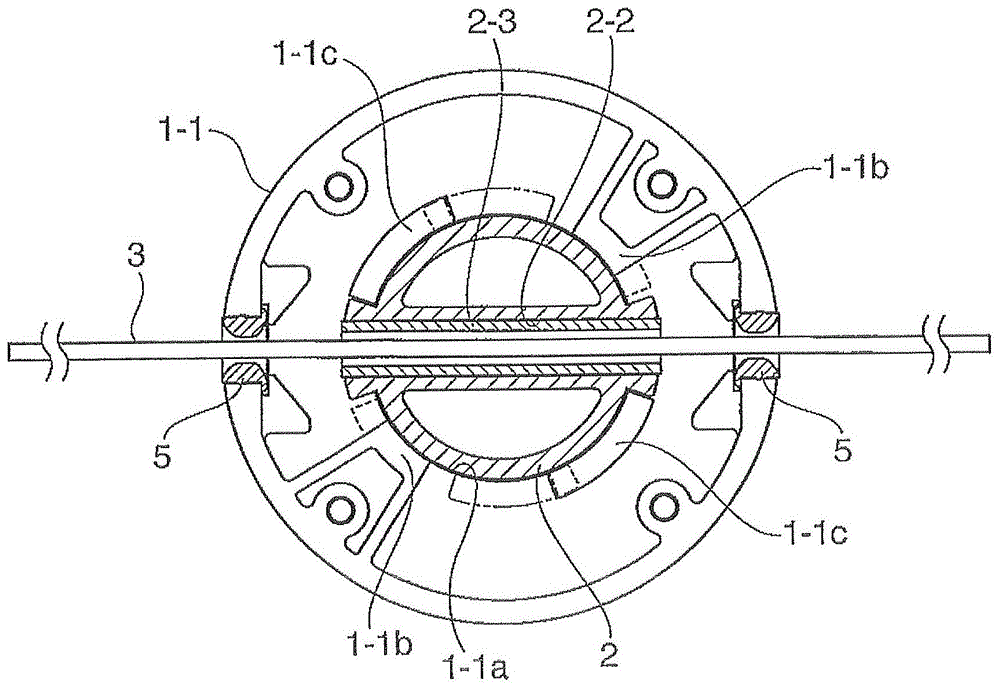

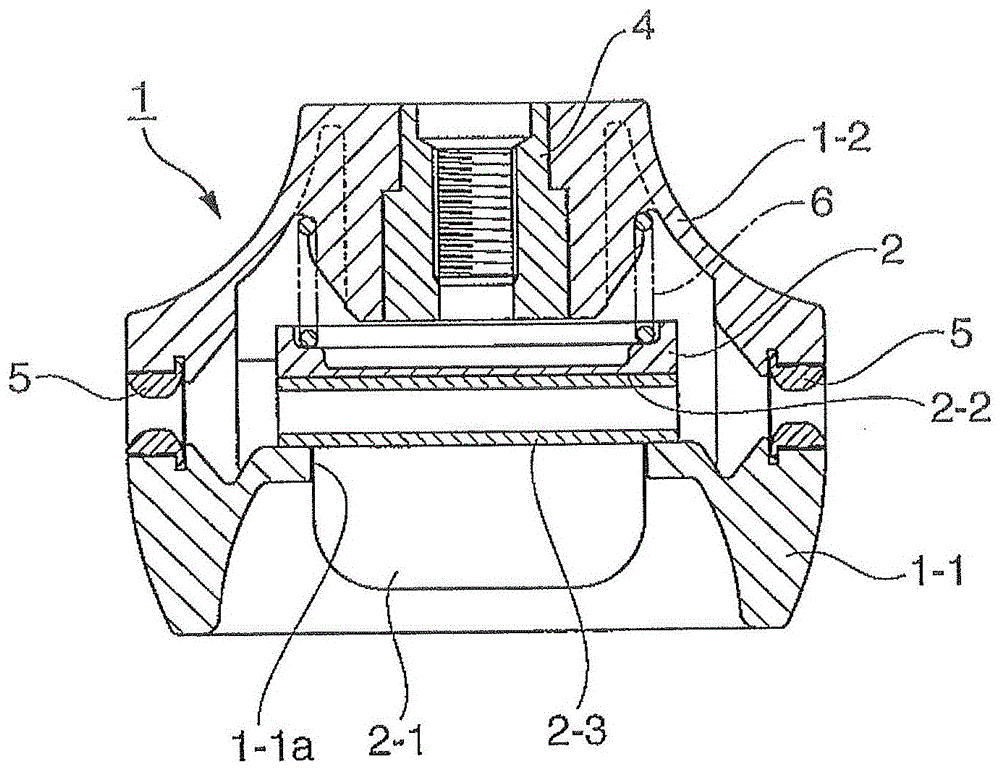

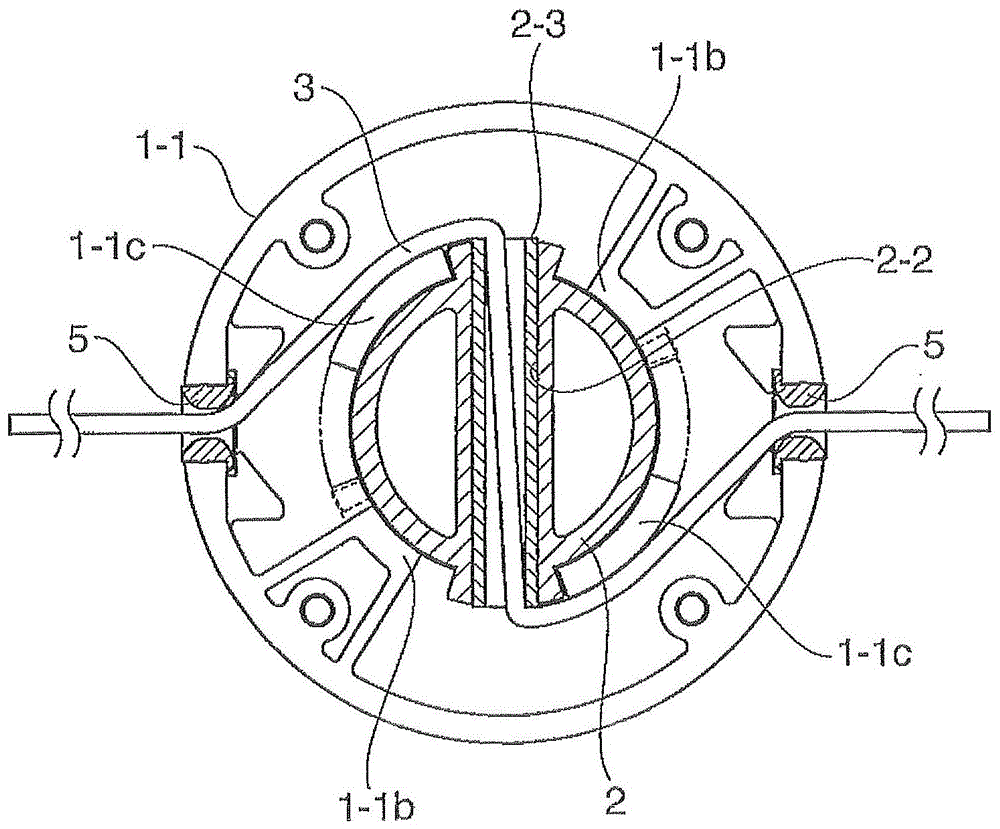

[0035] First, refer to figure 1 A rotary cutter for a lawnmower according to a first embodiment (pressure member pushing type) is described through FIG. 4 . In the rotary cutter of the first embodiment, attachment and removal of the cutting cord 3 are performed while pushing the pressure member. In this rotary cutter, a head main body 1 is composed of a housing 1-1 and a cover 1-2, and a pressure member 2 is interposed between the housing 1-1 and the cover 1-2. The pressure member 2 has a bottom cylindrical body, a flat sheet-shaped clamping portion 2-1 formed at the center of the bottom portion of the body, and a string insertion guide hole 2-2 formed at an open side of the body. The size of the string insertion guide hole 2-2 is larger than the thickness (diameter) of the cutting string 3, and extends parallel to the flat sheet-shaped clamping portion 2-1 in the radial direction. The rope support pipe 2-3 is fitted inside the guide hole 2-2. For example, the rope support ...

no. 2 example

[0047] Next, refer to Figure 5 to Figure 7 A rotary cutter for a lawnmower according to a second embodiment (pressure member pulling type) will be described. In the rotary cutter of the second embodiment, attachment and removal of the cutting cord 13 is performed while pulling the pressure member. In the rotary cutter, a head main body 11 is composed of a housing 11-1 and a cover 11-2, and a pressure member 12 is interposed between the housing 11-1 and the cover 11-2. The pressure member 12 comprises a bottomed and flanged cylindrical body. The main body of the pressure member 12 is longer than that of the pressure member 2 of the first embodiment. The pressure member 12 also includes a flat sheet-shaped clamping portion 12-1 formed at the center of the bottom portion of the main body and a cord insertion guide hole 12-2 formed close to an upper portion of the clamping portion 12-1. The size of the cord insertion guide hole 12-2 is larger than the thickness (diameter) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com