Funnel structure of two-in-one coffee maker

A coffee machine, two-in-one technology, applied in the direction of kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of large volume, low temperature, and large volume of the whole machine, and reduce the volume of the whole machine and reduce the packaging volume. , The effect of flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

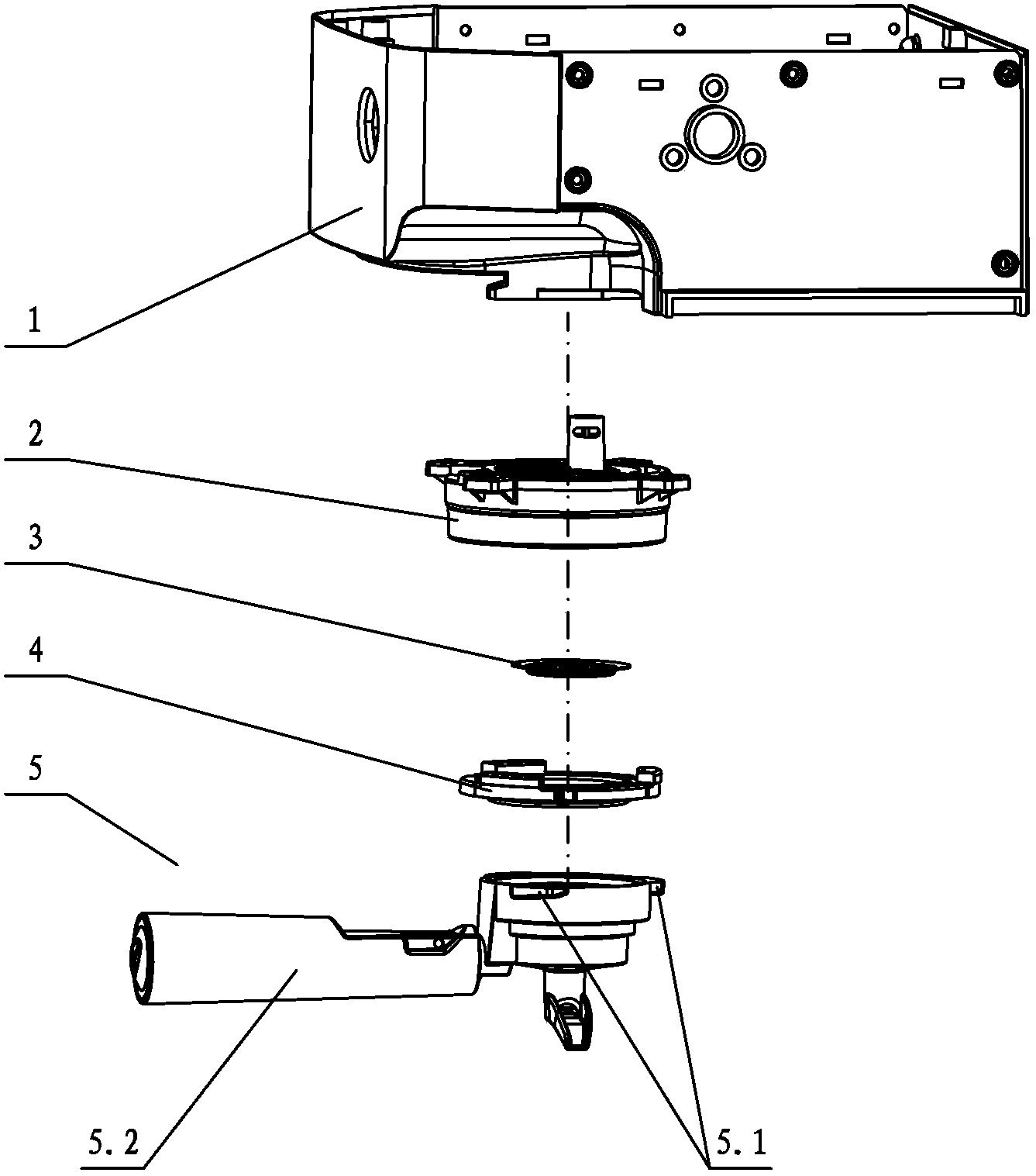

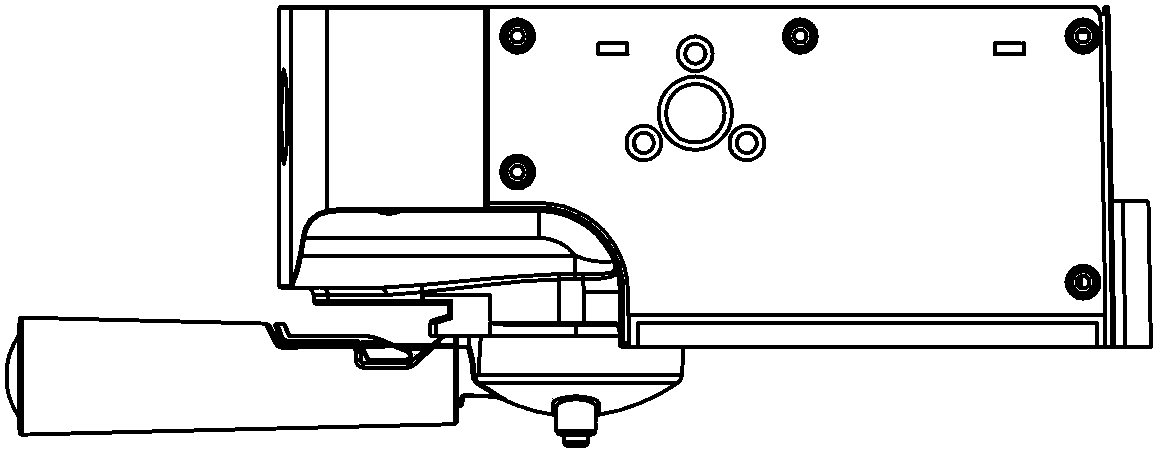

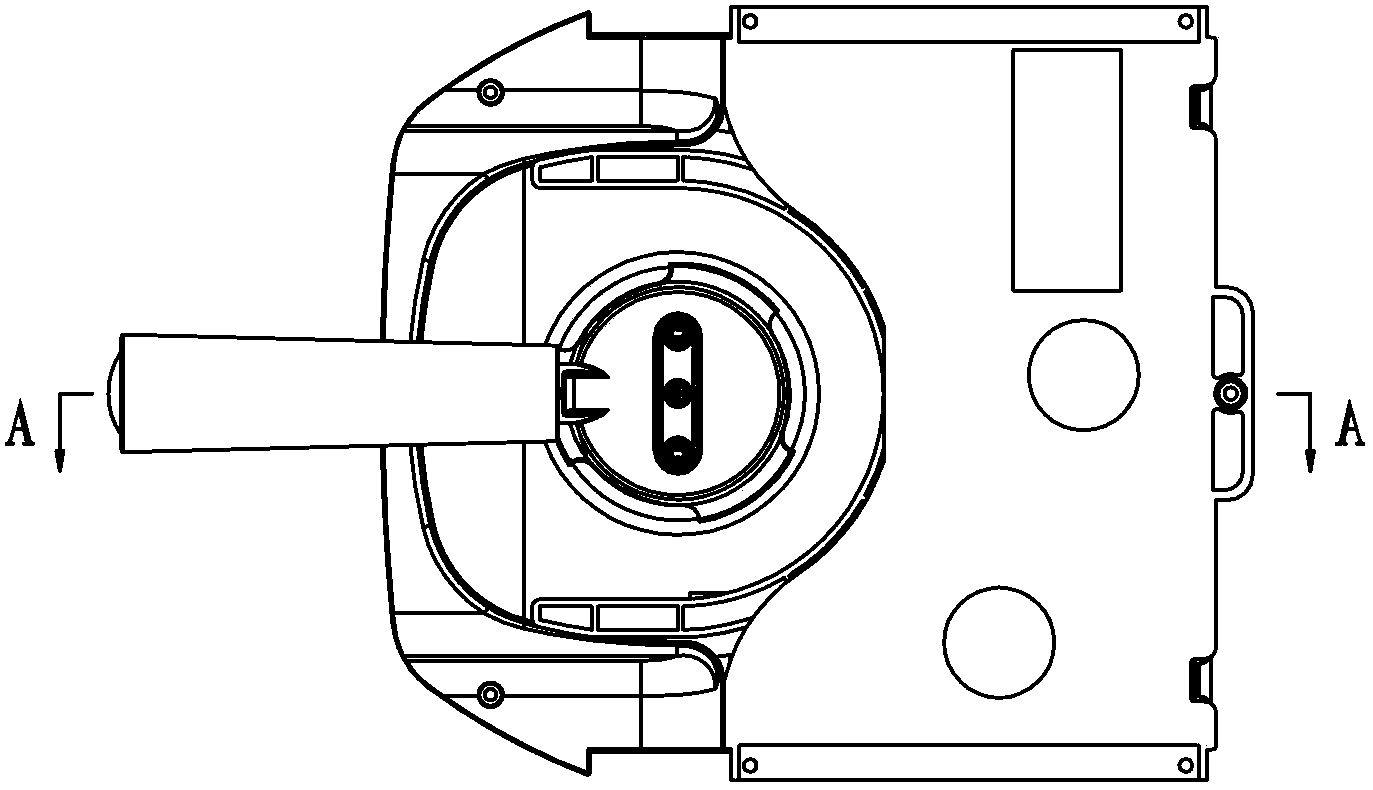

[0039] see Figure 1-Figure 4 , The funnel structure of the two-in-one coffee machine includes a bracket 1 arranged on the body, the bracket 1 is provided with a pressure coffee brewing mechanism and a drip coffee brewing mechanism, and the bracket 1 is also provided with a heating pot communicated with Water outlet 1.1.

[0040] The pressure coffee brewing mechanism includes a first assembly groove 1.2 provided on the bracket 1, the water outlet 1.1 is disposed above the first assembly groove 1.2, the outer circumference of the first pressure coffee funnel 5 is provided with a first flange 5.1, A pressure coffee funnel 5 is screwed into the bracket 1, the first flange 5.1 is inserted into the first assembly groove 1.2; the first assembly groove 1.2 and the first flange 5.1 are each more than two, the first assembly groove 1.2 and The first flanges 5.1 are respectively arranged at intervals.

[0041] The first pressure coffee funnel 5 is provided with a handle 5.2.

[0042]...

no. 2 example

[0045] see Figure 5-Figure 10 , in this embodiment, the drip coffee brewing mechanism includes a second assembly groove 1.3 provided on the bracket 1, the drip coffee funnel 7 is provided with a third flange 7.1, the drip coffee funnel 7 is inserted into the bracket 1, The third flange 7.1 is inserted into the second assembly groove 1.3.

[0046] The second assembly groove 1.3 is located outside the first assembly groove 1.2; the water outlet 1.1 is arranged above the second assembly groove 1.3.

[0047] For the rest of the undescribed parts, refer to the first embodiment, and will not be repeated here.

no. 3 example

[0049] see Figure 11-Figure 16 , in this embodiment, the pressurized coffee brewing mechanism includes a first assembly groove 1.2 provided on the bracket 1, the water outlet 1.1 is provided above the first assembly groove 1.2, and the outer circumference of the second pressurized coffee funnel 6 is provided with The second flange 6.1, the second pressure coffee funnel 6 is screwed into the bracket 1, and the second flange 6.1 is inserted into the first assembly groove 1.2.

[0050] There are more than two first assembling grooves 1.2 and second flanges 6.1 respectively, and the first assembling grooves 1.2 and the second flanges 6.1 are respectively arranged at intervals.

[0051] The outer periphery of the second pressure coffee funnel 6 is provided with one or more baffles 6.2.

[0052] A second assembly step 7.2 is provided on the inner wall of the drip coffee funnel 7, and the baffle plate 6.2 of the second pressure coffee funnel 6 rests on the second assembly step 7.2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com