Device for cleaning aircraft parts

一种清洁设备、清洁的技术,应用在使用液体的清洁方法、清洁方法和用具、飞机清洗等方向,能够解决用户有害、蒸气麻烦等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

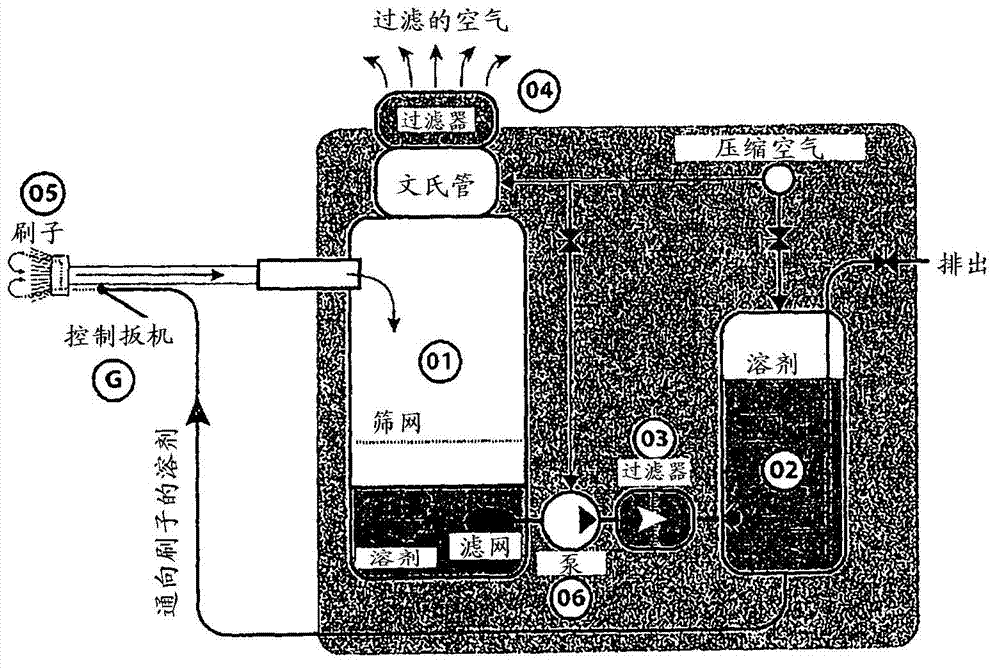

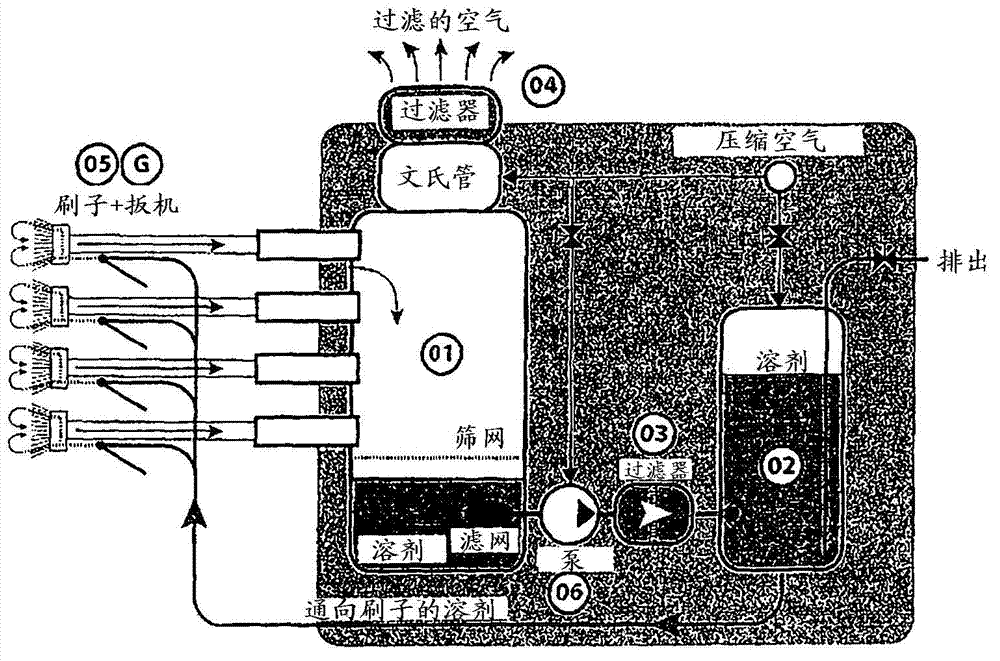

[0019] The invention takes the form of a system capable of delivering solvent to dirty parts and then pumping the mixture.

[0020] Similar to application by a paint brush, the present invention delivers the solvent to a special brush. Any solvent can be used by the system, but the most widely used are the DIESTONE range of solvents (DLS, A8287, A8284, A8290, D, DLS / UV, E, G11, HFP, M-SK, M-TK, S), Products of the SOCOMORE trademark. The aerospace industry currently has only one solvent approved for use by all products involved in this operation.

[0021] This system enables counterparts to "brush" the part to be cleaned by providing solvent in a controlled manner, but instead of applying it by a paint brush, the system recovers the dirty product (solvent + debris + cutting oil), disposes of it (filtering), and send it back to the brush again. The solvent is thus recycled, which enables considerable solvent savings. Cleaned parts can be metallic, or made of composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com