Multilayer composite hand bag with eight edge sealing strips

A multi-layer composite and multi-layer composite film technology, applied in the field of handbags, can solve the problems of complex manufacturing process, poor standing stability, inconvenient folding, etc., and achieve the effect of high structural strength, compact structure, and easy folding and carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

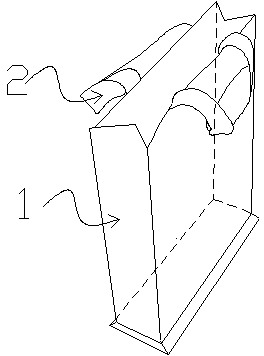

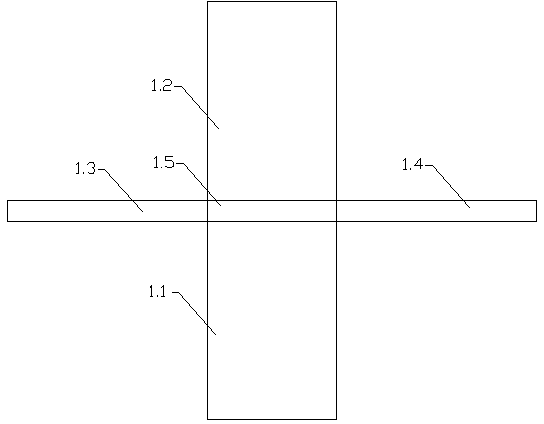

[0015] see figure 1 and figure 2 , the present invention relates to a kind of multi-layer composite handbag with eight edges, which includes a bag body 1 and a handle strap 2 arranged on the bag body 1, and the bag body 1 includes a vertical front sheet body 1.1, a rear sheet body 1.2, the left sheet body 1.3, the right sheet body 1.4 and the flat negative sheet body 1.5, the front sheet body 1.1, the rear sheet body 1.2, the left sheet body 1.3, the right sheet body 1.4 and the negative sheet body 1.5 are all rectangular structures. Layer composite film, the shape and size of the front sheet body 1.1 and the back sheet body 1.2 are the same, the shape and size of the left sheet body 1.3 and the right sheet body 1.4 are the same, the front sheet body 1.1, the back sheet body 1.2, the left sheet body The heights of body 1.3 and right body 1.4 are the same, the lengths of the front and rear sides of said negative body 1.5 are the same as the lengths of the lower sides of front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com