Feedstock conveying device of stainless steel solid melting furnace

A conveying device, stainless steel technology, applied in furnaces, furnace components, furnace types, etc., can solve the problems of reducing the frequency of chain replacement, affecting work efficiency, and changing chains, etc., to improve work efficiency, reduce production costs, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

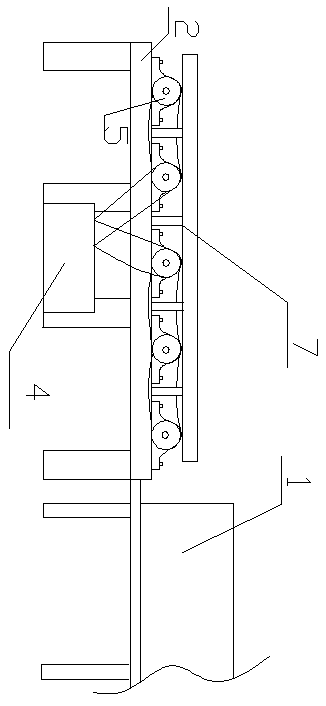

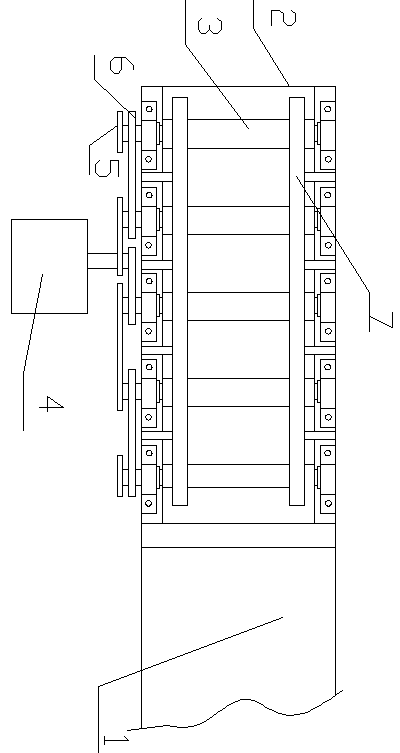

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0014] Such as figure 1 , 2 Shown: a feeding conveying device of a stainless steel solid melting furnace in this embodiment, including a solid melting furnace 1, a feeding conveying device is provided on one side of the feed port of the solid melting furnace 1, and the feeding conveying device includes a conveying frame 2. Roller 3, motor 4, baffle plate 7, first roller gear 5 and second roller gear 6, the output shaft of the motor 4 is fixedly provided with internal and external gears, wherein two of each roller 3 Bearings with seats at the ends are fixed on both sides of the conveyor frame 2 for rotation, and one end of each roller 3 is provided with a first roller gear 5 and a second roller gear 6 axially forward and backward, and the motor 4 Both the internal and external gears are cross-connected with one of the second roller gears 6 and one of the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com