Automatic two-stage speed changing mechanism for electric vehicle

An automatic transmission, electric vehicle technology, applied in mechanical equipment, transmission, transmission parts, etc., can solve the problems of reduced endurance, increased output horsepower of motor 72, poor transmission efficiency of the mechanism, etc., to achieve improved endurance, optimal transmission efficiency, The effect of saving electricity demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

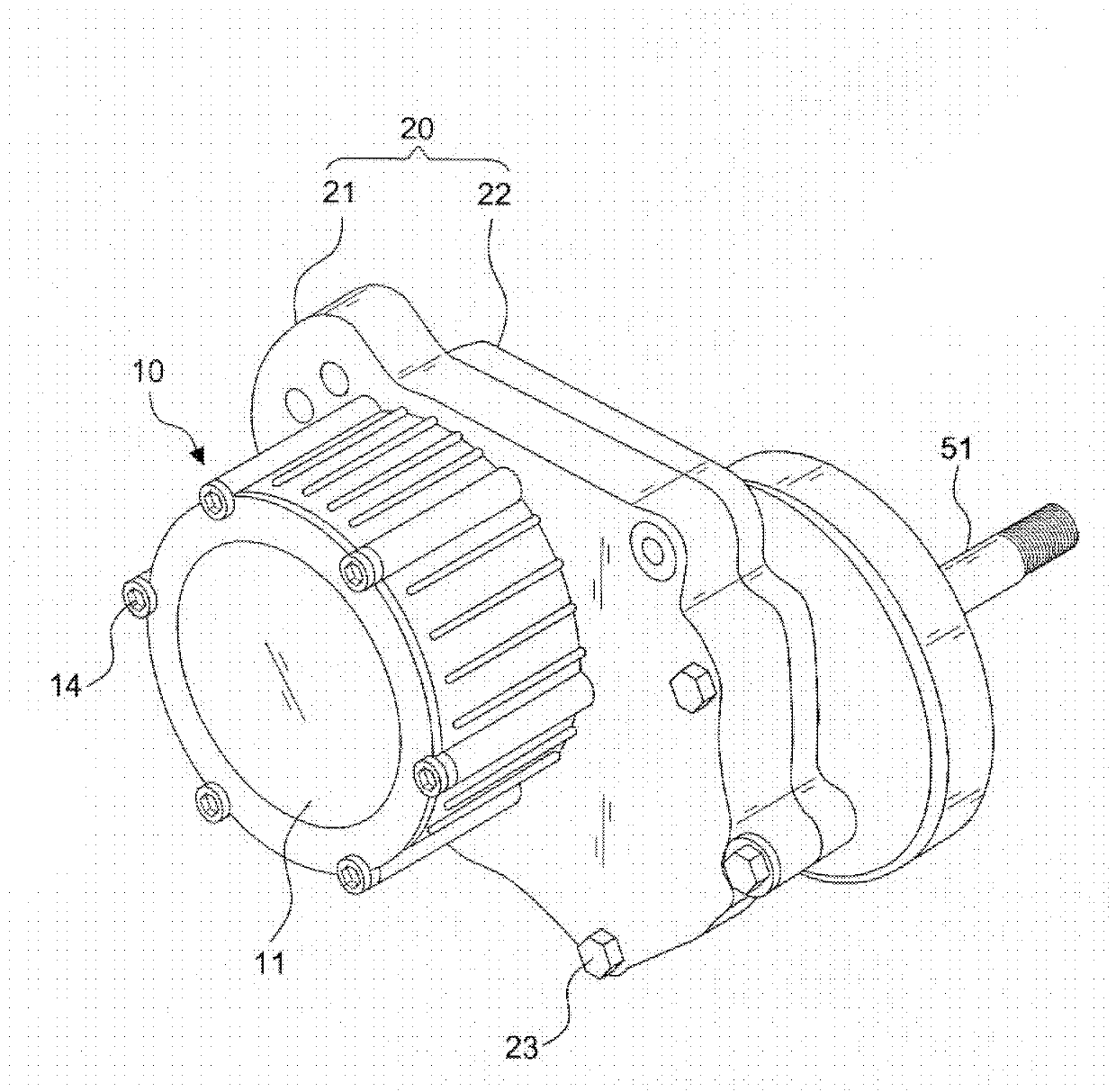

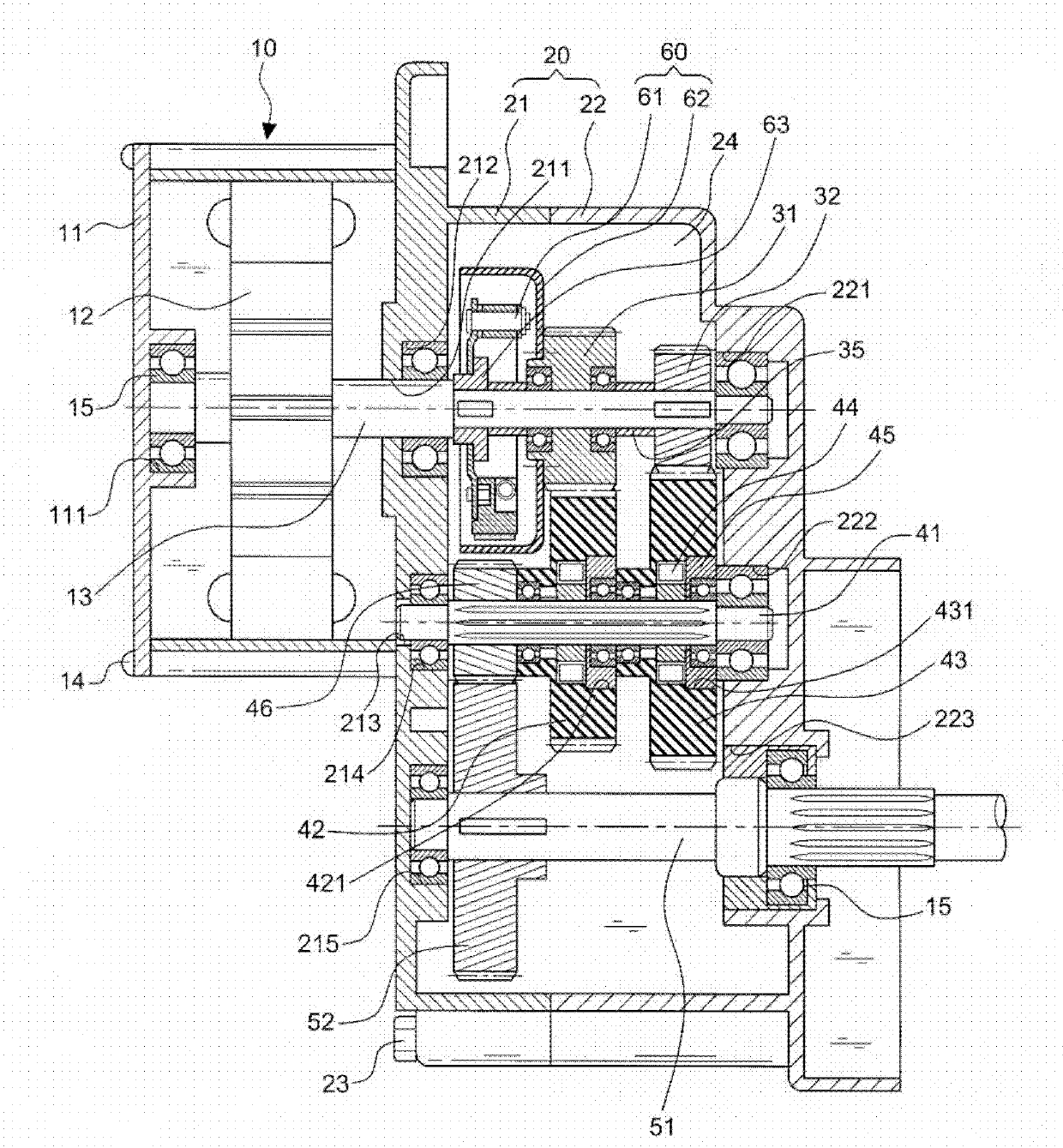

[0083] First, see Figure 2 to Figure 9 As shown, a possible embodiment of the present invention includes:

[0084] A gearbox housing 20, including an outer shell 21 and an inner shell 22, the inner and outer shells 21 / 22 are locked with several screws 23, and the accommodating space 24 formed by it is used to accommodate the required speed change Components: the shell 21 is provided with a first shaft hole 211 , a first shaft seat 212 , a second shaft hole 213 , a second shaft seat 214 , and a third shaft seat 215 at relevant positions; the inner shell 22 corresponds to the outer shell 21 A fourth shaft seat 221 , a fifth shaft seat 222 , and a sixth shaft seat 223 are provided at the relevant positions; each of the aforementioned shaft seats is individually embedded with a ball bearing 15 .

[0085] A motor 10, including a motor housing 11, a rotary member 12, and an input shaft 13, is locked on the outside of the gearbox housing 20 with several screws 14, and the motor hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com