Adjustable gradient acoustic impedance matching layer

A technology of acoustic impedance and matching layer, which is applied in the field of ultrasonic transducers and acoustic detection, can solve problems such as complex artificial periodic structure, complicated matching layer manufacturing, and inability to meet working conditions and environments, so as to achieve good transmission efficiency and enhance flexibility and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described now in conjunction with accompanying drawing.

[0036] The invention provides an adjustable gradient acoustic impedance matching layer. The gradient of the acoustic impedance matching layer can be adjusted accurately, which can improve the transmittance of acoustic energy and enhance the flexibility and practicability of the acoustic impedance matching layer.

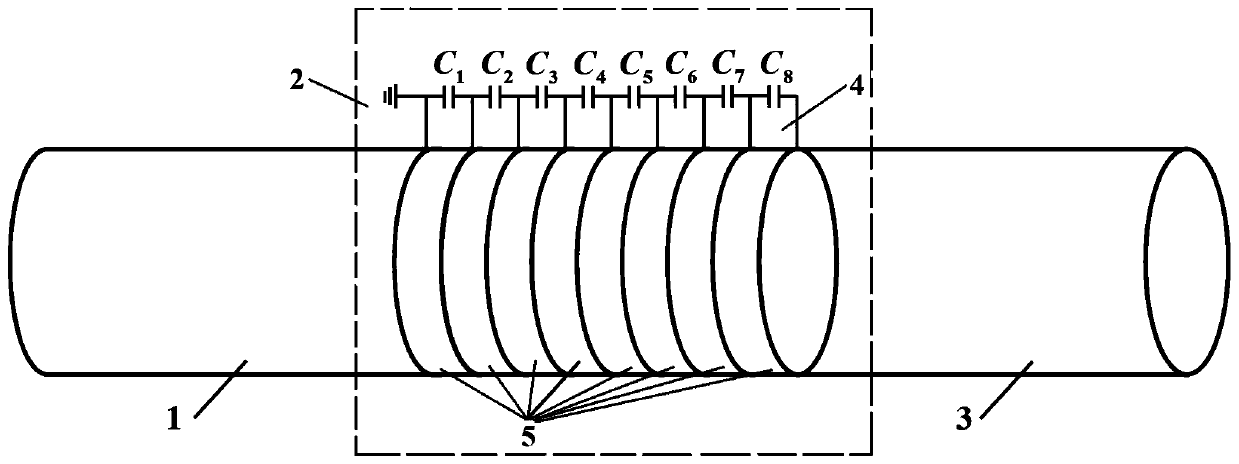

[0037] Such as figure 1 As shown, the acoustic impedance matching layer 2 includes: a first material to be matched 1, a piezoelectric ceramic layer 2, and a second material to be matched 3; the piezoelectric ceramic layer 2 includes a plurality of serially connected piezoelectric ceramic sheets 5 and Corresponding external shunt circuit 4;

[0038] The piezoelectric ceramic layer 2 is installed between the first material to be matched 1 and the second material to be matched 3, and each piezoelectric ceramic sheet 5 is independently connected to an external shunt ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com