Motor-driven three-way valve

An electric three-way valve and valve seat technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve the problems of reduced magnetic characteristics of stepper motors, large output power of stepper motors, and no consideration of valve core shape, etc. Achieve the effect of realizing opening and closing, avoiding large-scale, and realizing the reduction of occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

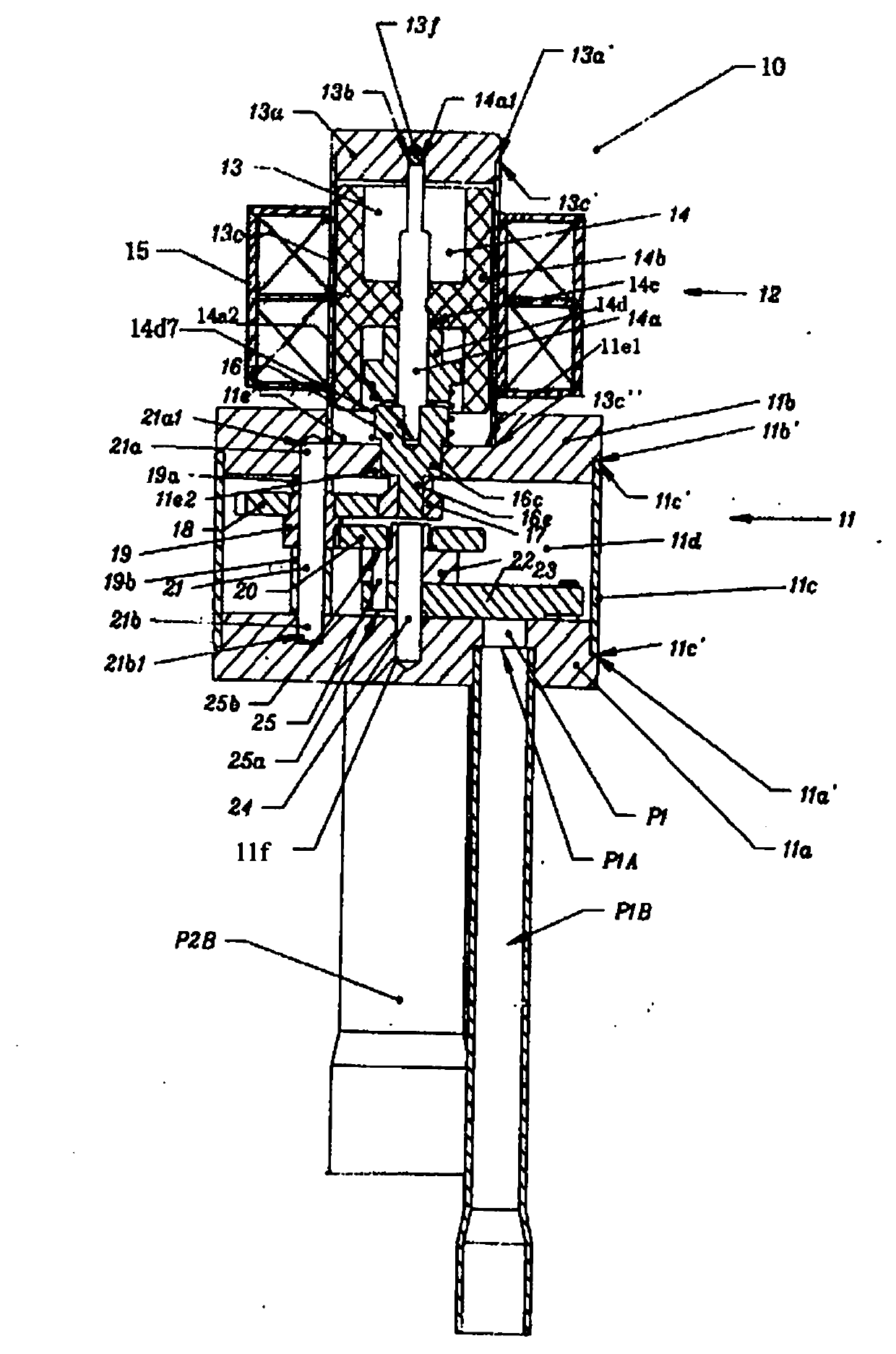

[0027] Such as figure 1 The illustrated electric three-way valve 10 is composed of a cylindrical housing 11 of a metal material such as stainless steel and a motor portion 12 . The above-mentioned motor part 12 is made of a non-magnetic metal material such as a cylindrical shell 13 made of stainless steel, a rotor 14 and a rotor shaft 14a disposed in the above-mentioned shell, and are externally embedded in the outside of the above-mentioned shell 13, and are fixed as a stator to drive the above-mentioned rotor 14. Composed of coils 15, the motor unit 12 is separated from the housing 11 and is arranged above the outer housing 11 in the figure.

[0028] The above-mentioned cylindrical housing 11 is made of a metal material such as a disc-shaped valve seat 11a of stainless steel, and a metal material such as a disc-shaped flat plate 11b of stainless steel disposed on the valve seat 11a as an upper end surface. A cylindrical side wall 11c is formed between the seat 11a and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com