Parallel type lapping apparatus used for fireproof cable insulation layer mica tape lapping

A technology for fire-resistant cables and mica tapes, which is applied in the direction of insulating conductors/cables, can solve the problems of increasing the length of equipment, limited wrapping length, and restricting the production of large-length fire-resistant cables, so as to reduce equipment costs and reduce equipment length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

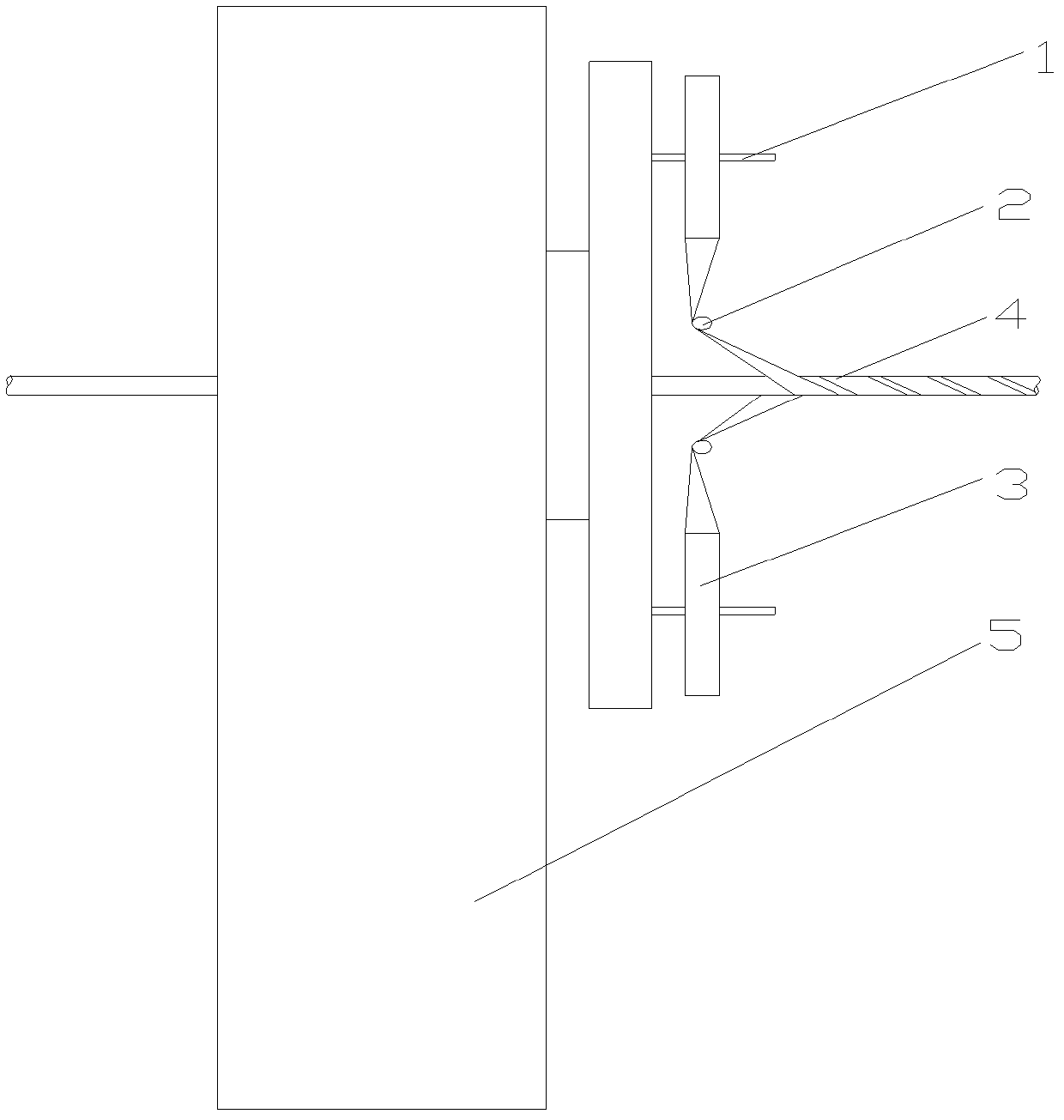

[0014] like figure 1 As shown, a parallel wrapping device for fireproof cable insulation layer mica tape wrapping, including a wrapping frame and a rotary wrapping head, the rotary wrapping head is fixed on the wrapping frame, and is transported through the wrapping frame The power drives the rotary wrapping head to rotate. The rotary wrapping head 5 includes a tape loading frame 1 and two parallel tape guide rods 2. The tape loading frame 1 is a tape loading reel for loading the mica tape. The belt rods 2 are respectively located at the upper and lower positions of the cable conductors to be wrapped. The mica tape 3 is arranged on the tape loading frame 1. The transmission power of the wrapping frame drives the tape loading frame 1 to drive the mica tape 3 to rotate, and the cable conductor 4 passes through the two tape guide rods at a constant speed. 2, the mica tape 3 is guided by the tape guide rod 2 to wrap evenly and orderly on the cable conductor 4.

[0015] The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com