Connector

A technology of connectors and substrates, which is applied in the direction of connections, parts of connecting devices, electrical components, etc., can solve problems such as the reduction of the overall strength of the casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

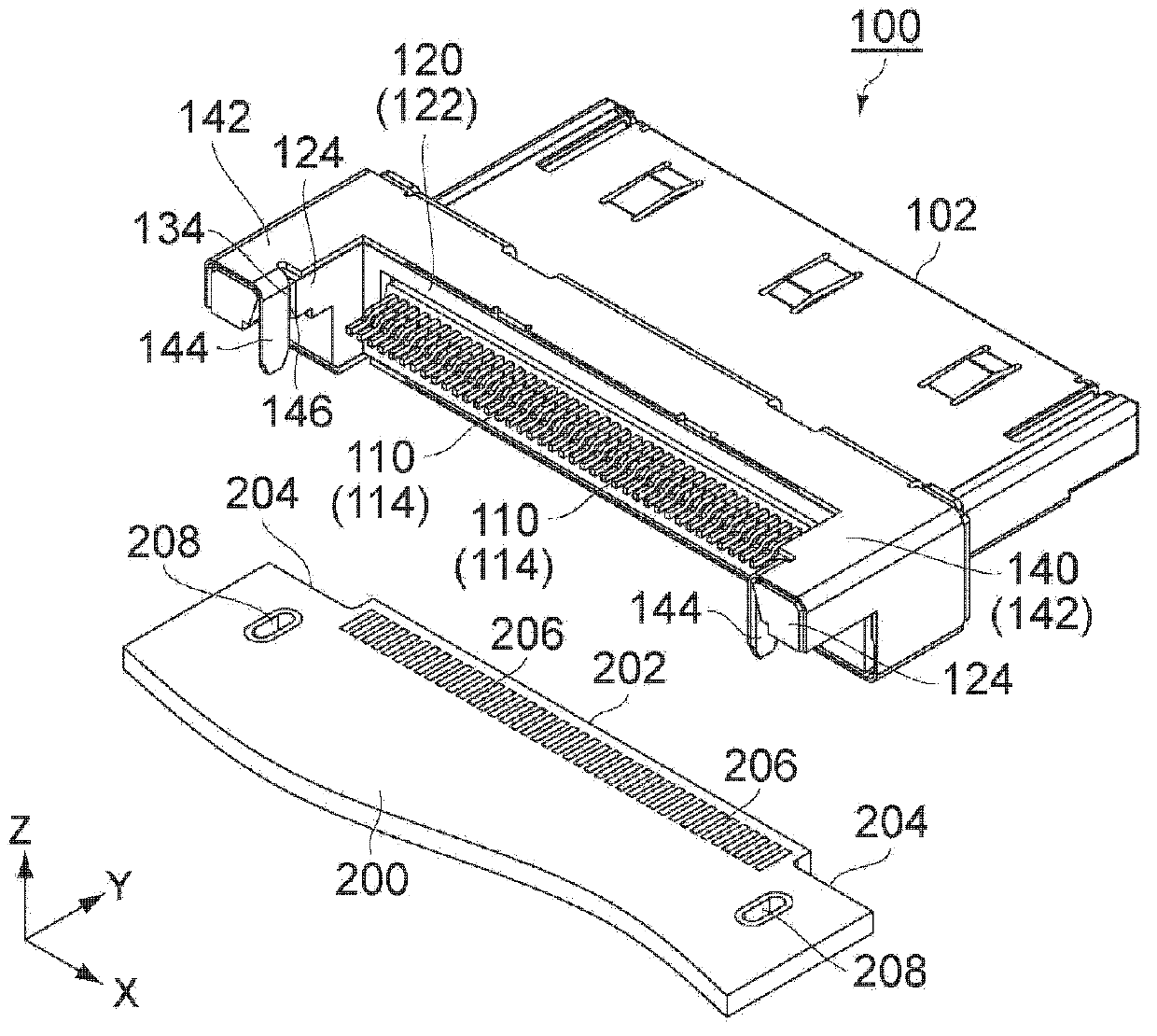

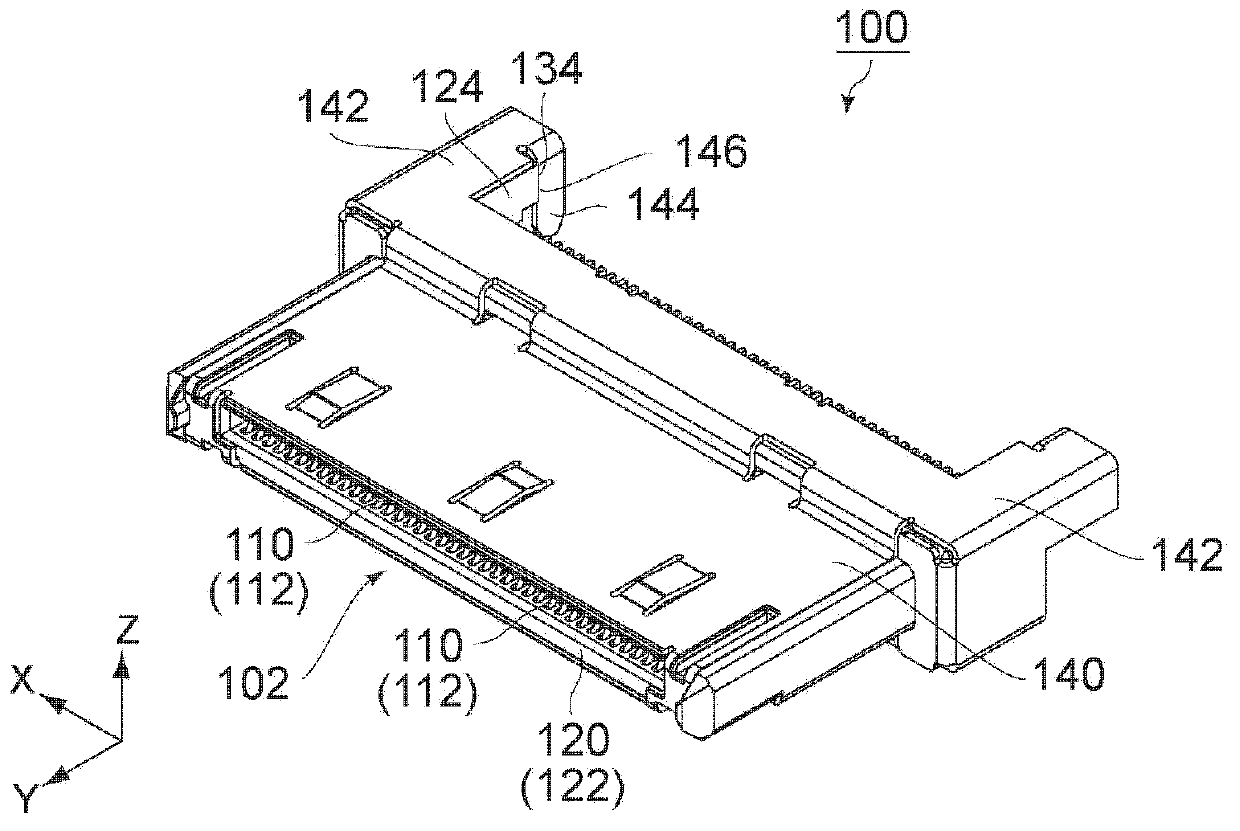

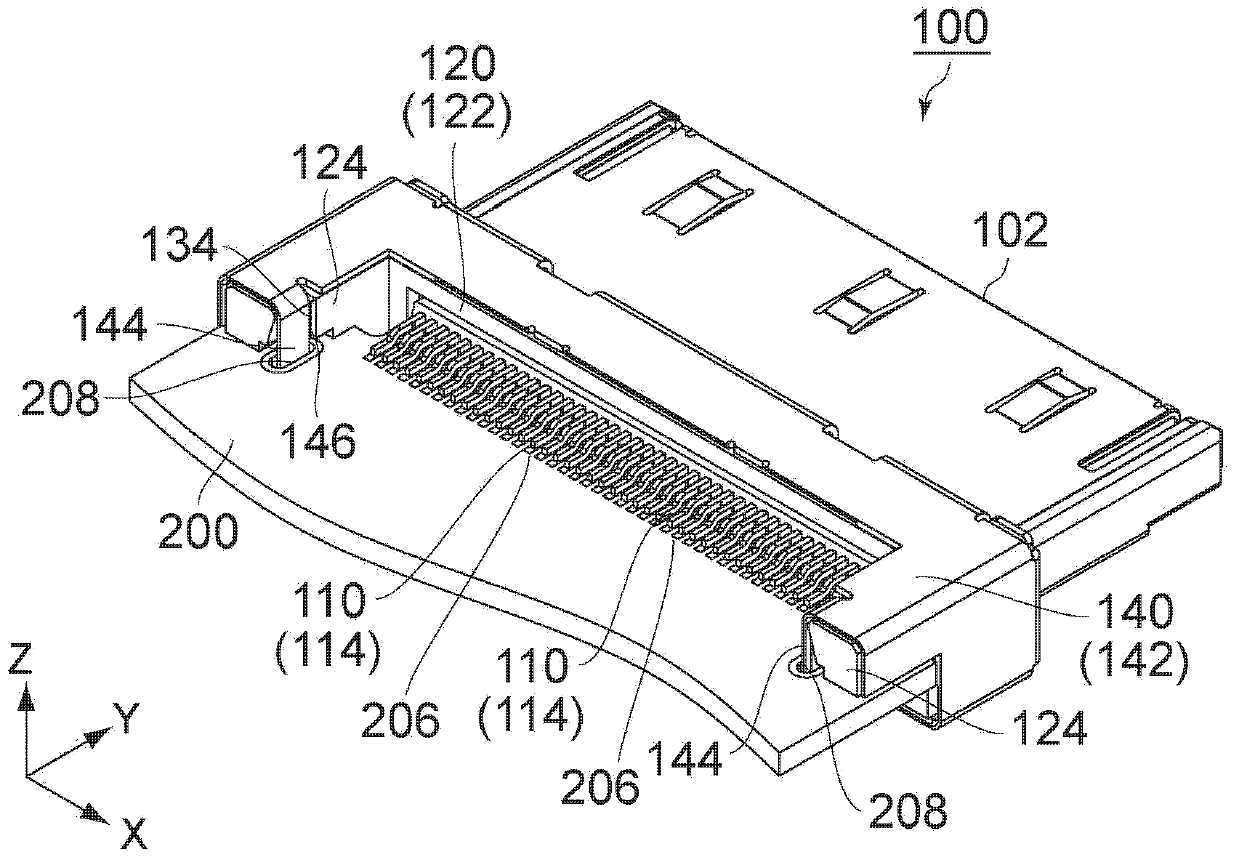

[0023] refer to figure 1 with image 3 , the connector 100 according to the first embodiment of the present invention is a plug connector. The connector 100 has a fitting portion 102 that is fitted with a fitting portion of a mating connector (receptacle connector: not shown). The fitting portion 102 is formed on the +Y (front) side of the connector 100 . In use, the connector 100 is mounted and fixed on the substrate 200 in a state where the fitting portion 102 protrudes in the +Y direction (forward) from the edge 202 of the substrate 200 . Such as figure 1 As shown, the substrate 200 is formed with two shoulders 204 . Each shoulder 204 is recessed from the edge 202 of the substrate 200 in the -Y direction (backward). A plurality of pads 206 are formed on the substrate 200 . A plurality of pads 206 are positioned proximate edge 202 and between shoulders 204 in the X direction (pitch direction). Two through holes 208 are formed on the substrate 200 . The through hole...

no. 2 example

[0038] refer to Figure 8 with Figure 9 , the connector 100A according to the second embodiment of the present invention is the connector 100 of the first embodiment (refer to figure 1 with image 3 ) modification example. The connector 100A of the second embodiment includes almost the same structure as the connector 100 of the first embodiment. Thus, in Figure 8 with Figure 9 In , the same reference numerals are given to components similar to those of the first embodiment, and therefore, detailed descriptions of these components will be omitted.

[0039] Such as Figure 8 with Figure 9 As shown, the connector 100A of the embodiment and the connector 100 (refer to figure 1 with image 3 ) differ only in the structural aspect of the housing fixing part. Therefore, the substrate 200A on which the connector 100A of the present embodiment is mounted is different from the substrate 200 of the first embodiment.

[0040] More specifically, as figure 1 with image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com