The structure of the pressing wheel assembly of a paper corner protection automatic coiling device

A component structure and compression wheel technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems that boxes cannot be stacked in multiple layers, occupy a large space, and have large gaps in packaging cardboard, so as to facilitate manual observation and occupy The effect of small site and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

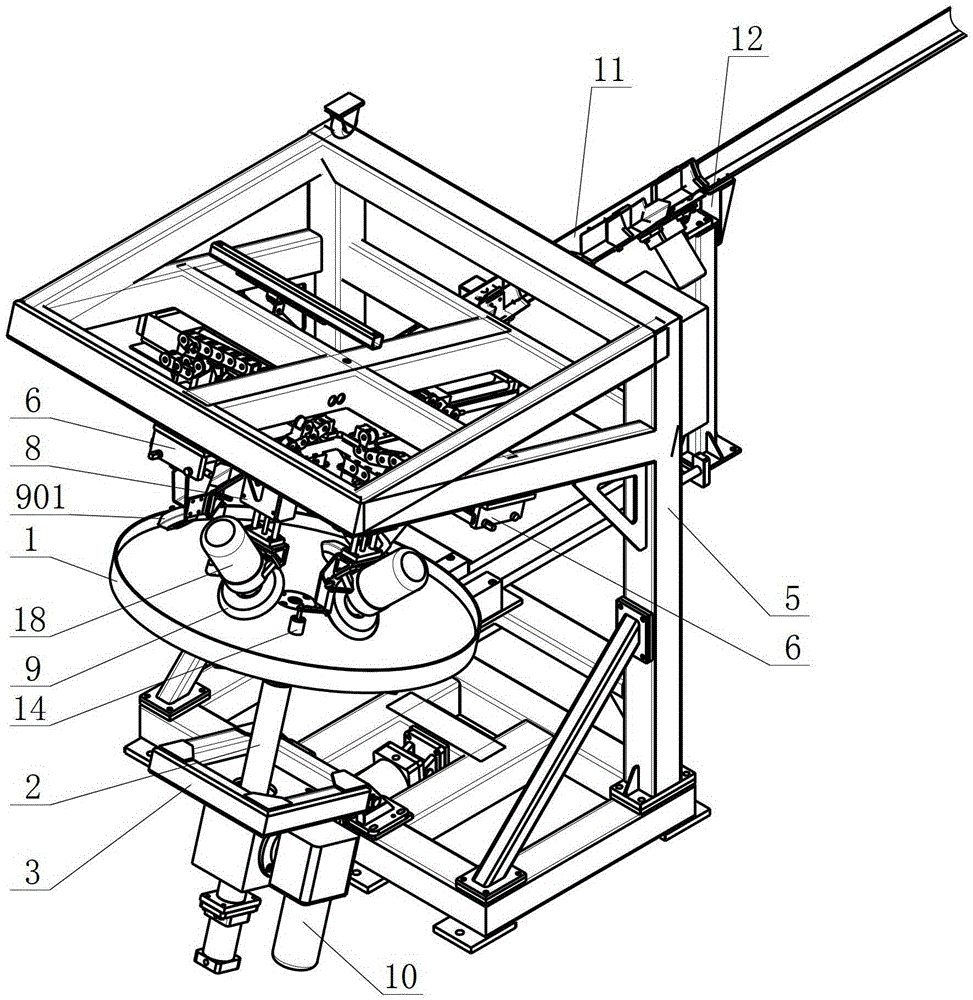

[0059] The present invention will be further described below in conjunction with accompanying drawing.

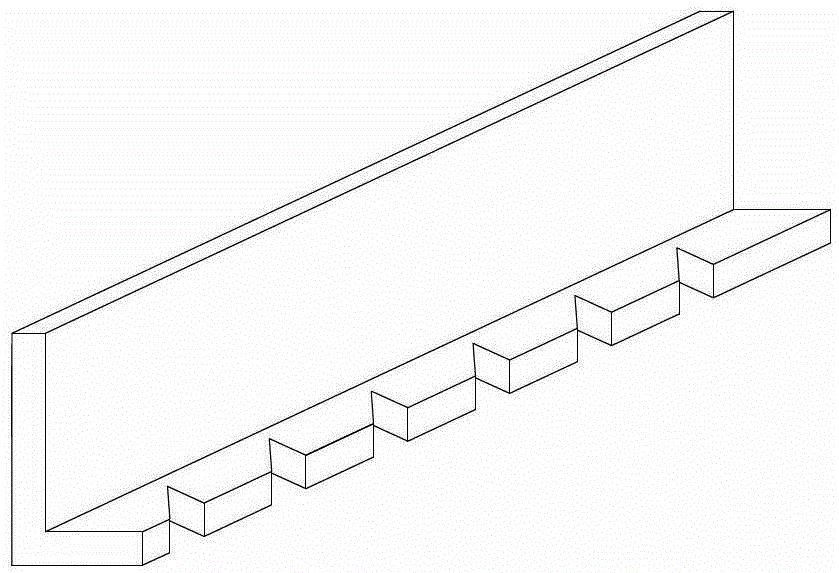

[0060] figure 1 Among them, the paper corner protector is a long strip of 90° bent paper tape, and a plurality of gaps are opened at intervals on one right angle surface.

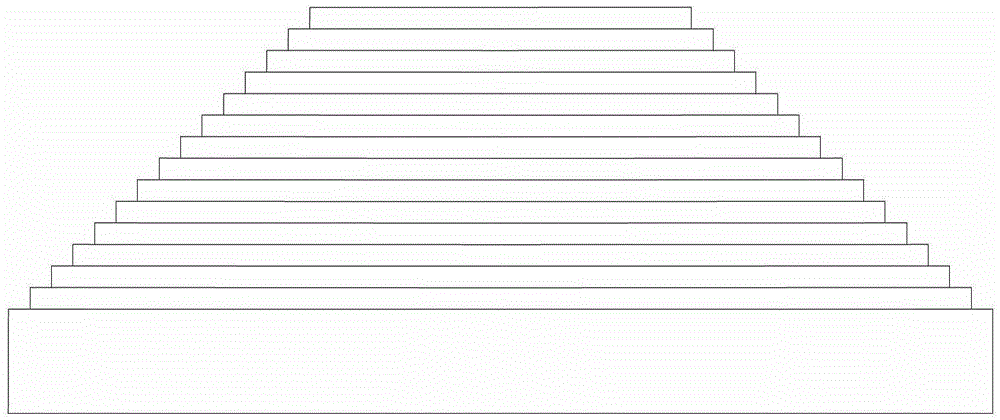

[0061] The device includes a turntable assembly, a guide feeding trough assembly and a pressing wheel assembly arranged from bottom to top.

[0062] Such as Figure 11 , Figure 12 As shown, the structure of the turntable assembly is:

[0063] The turntable 1 is a circular disk surface, and its outer edge is bent upward perpendicular to the surface of the disk to form a ring-shaped side wall. The upper end of the vertically arranged rotating shaft 2 is installed at the center of the bottom of the turntable 1 perpendicular to the surface of the turntable 1. The turntable 1 can be opposite The rotating shaft 2 rotates around its axis, the lower end of the rotating shaft 2 is a free end, and a rack segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com