A bracket for a turbocharger

A technology of turbocharger and supercharger, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of numerous pipelines, difficult system layout and production line assembly, complicated turbocharger system layout, etc. Simplify system layout, improve assembly conditions, reduce the effect of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

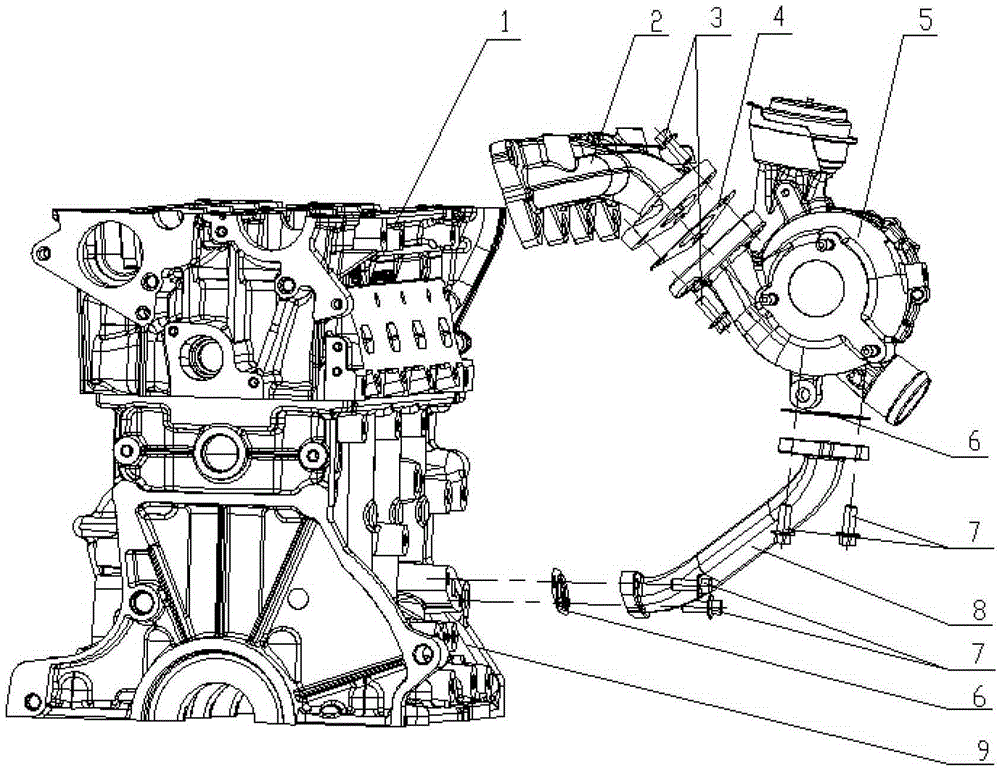

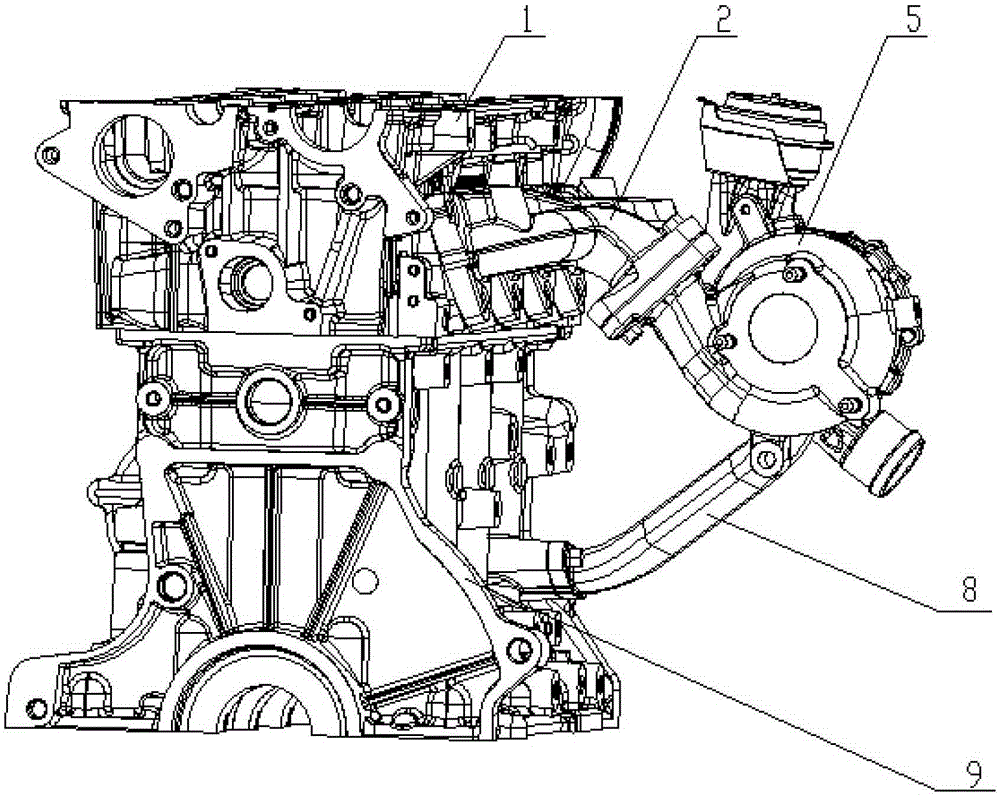

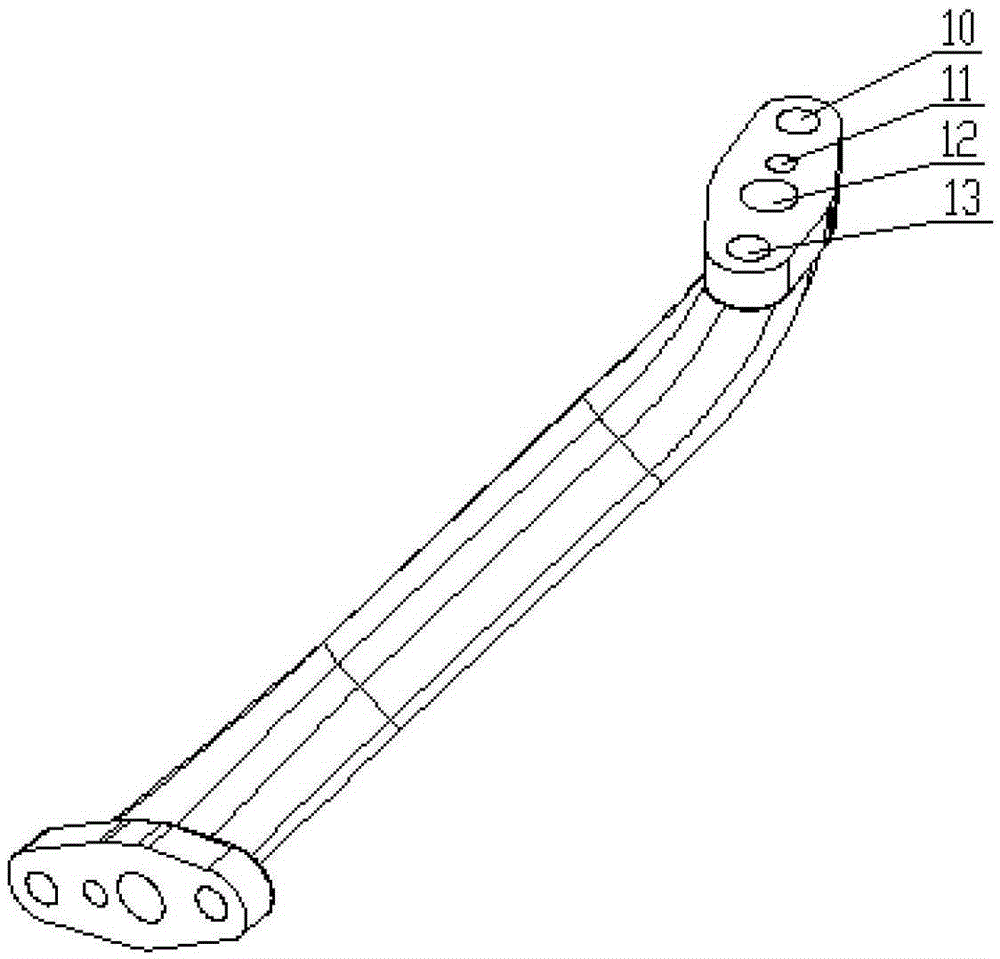

[0030] Such as figure 1 As shown, like all turbocharged engines, the turbocharger 5 is arranged on the exhaust manifold 2, and a supercharger bracket 8 is arranged between the turbocharger 5 and the engine block 9, respectively through two The bolts 7 are installed on the supercharger 5 and the cylinder body 9 to effectively support and fix the supercharger 5 . At the same time, the supercharger bracket 8 is provided with a bracket oil inlet channel 11 and a bracket oil return channel 12 . One end of the bracket oil inlet passage 11 is connected to the main oil passage 19 of the lubrication system on the cylinder body through the oil inlet passage 17 on the cylinder body, and the other end is connected to the supercharger side oil inlet passage B22 through the supercharger side oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com