check valve

A technology for check valves and valve seats, applied in valve details, control valves, valve devices, etc., can solve the problems of not having a spring closing valve force mechanism, shortening the life of check valves, increasing the number of parts, etc., to achieve guaranteed life , the effect of suppressing abnormal noise and increasing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

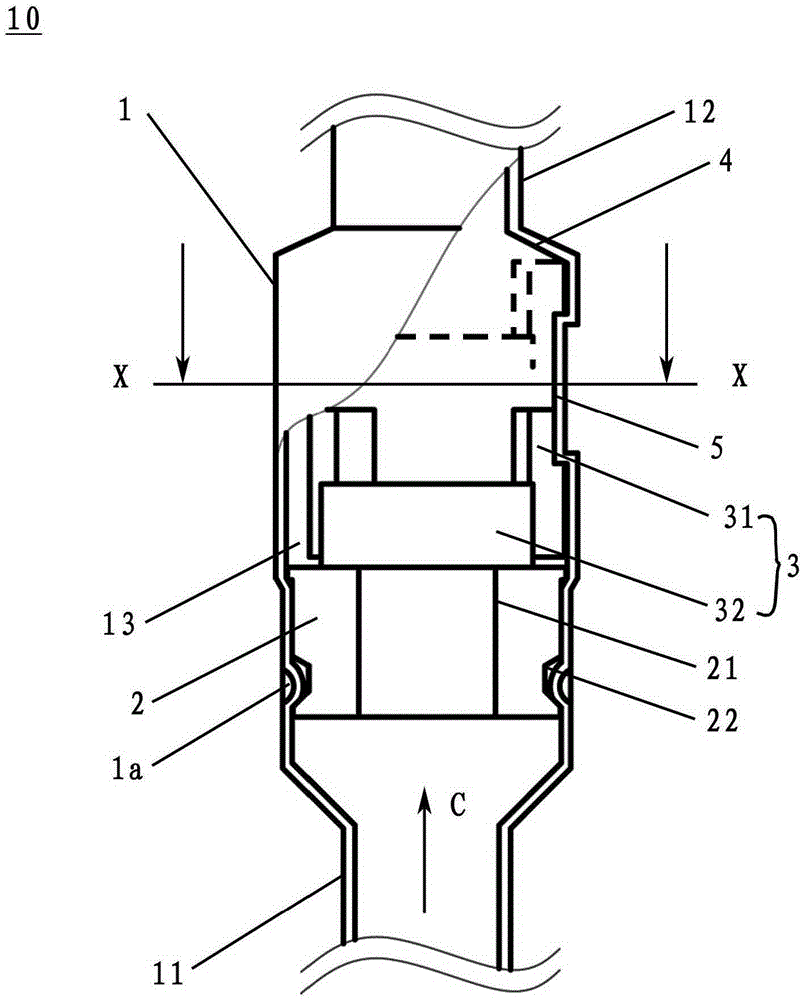

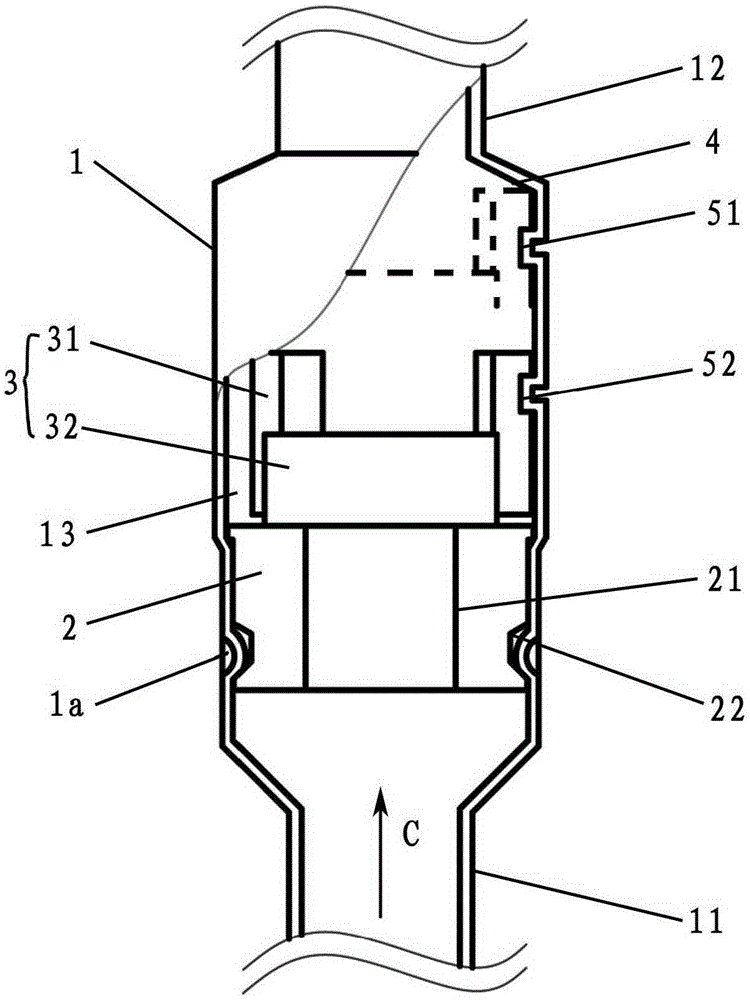

[0036] Hereinafter, the check valve of the present invention will be described with reference to the drawings.

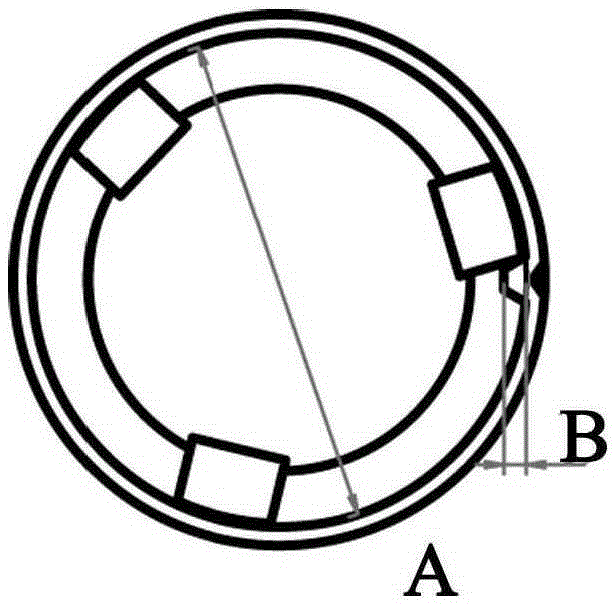

[0037] The check valve 10 is a vertically placed check valve, and includes a metal valve body 1 and a valve body 3 . A valve seat member 2 serving as a “valve seat portion” is provided inside the valve main body 1 . In the valve body 1 , a small-diameter inlet pipe portion 11 and an outlet pipe portion 12 are integrally formed (for example, press-processed), and a large-diameter valve chamber 13 is formed in the center thereof. In addition, a limiting portion 4 is formed on a boundary portion between the outlet pipe portion 12 and the valve chamber 13 of the valve main body 1 . A valve port 21 is formed at the center of the valve seat member 2 attached to the valve main body 1 by being press-fitted toward the introduction pipe portion 11 in the valve chamber 13 . Furthermore, caulking and fixing are performed by a concave portion 22 formed on the outer periphery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com